316L Outdoor Camping Pot

- Material: 316l Stainless Steel

- Stamping Size: Custom

- Stamping Type: Metal Spinning

- Stamping Mold: Metal Spinning Molds

- Spinning Thickness: 1.5(mm)

- Post-Processing: Custom

- Spinning Material: Stainless Steel Spinning

- Surface Treatment: Anodized Oxidation

- Application: Cookware

High-Quality Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

In the world of outdoor adventures, having the right gear is essential for both survival and enjoyment. Among the most crucial pieces of equipment is a reliable cooking pot. Enter the prototype CNC spun stainless steel 316L outdoor camping pot, a marvel of modern engineering designed to meet the rigorous demands of outdoor enthusiasts.

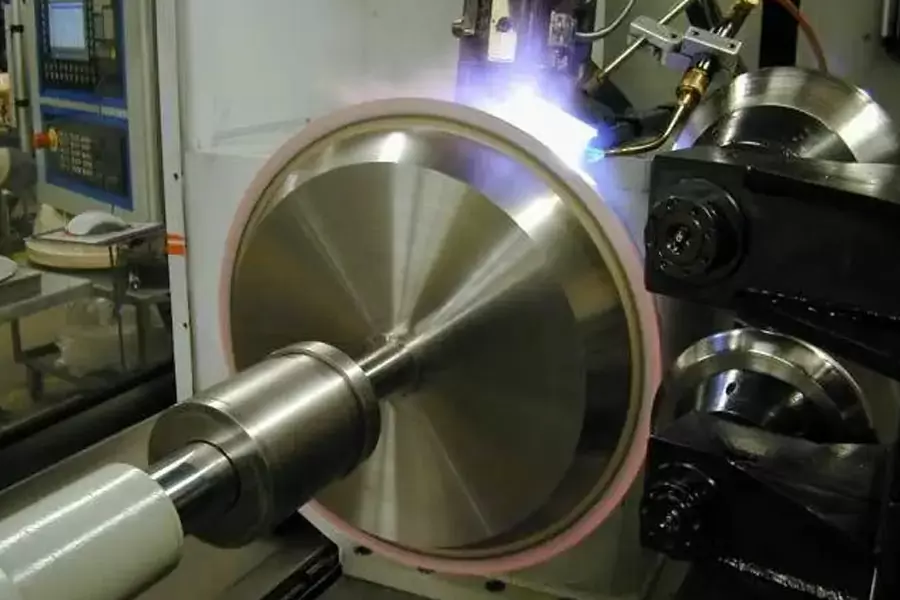

Computer Numerical Control (CNC) spinning is a sophisticated manufacturing process that combines the precision of CNC machining with the traditional art of metal spinning. In this process, a metal disc is rotated at high speeds while a CNC-controlled tool shapes it into the desired form. This method is particularly advantageous for creating uniform, high-quality products with intricate designs. The prototype CNC spun camping pot benefits immensely from this technology, ensuring consistent thickness, superior strength, and an impeccable finish.

Our state-of-the-art CNC (Computer Numerical Control) spinning technology ensures each camping pot is crafted with exceptional precision. This process allows for consistent and accurate production, maintaining the highest standards of quality across all units.

We utilize Stainless Steel 316L, renowned for its superior resistance to corrosion and extreme temperatures. This makes our camping pots not only robust and long-lasting but also safe for cooking in diverse outdoor conditions.Understanding that every camper has unique needs, we offer custom prototyping services. Whether you need a specific size, shape, or feature, our team can create a prototype tailored to your exact specifications, ensuring the final product meets all your requirements.

Why Choose Our Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot Service?

- Tooling. Metal spinning of exotic or super alloys does require tooling, however the tooling in most cases will last for the lifetime of the product. Be-cu.com’s experience in spin tool development allows optimized tooling, such that thinning, follow on trimming and material spring back are controlled.

- Prototyping. Because tooling is minimized metal spinning can be a good fit for prototyping of complex components. As the design concept evolves tooling may be adjusted to match the part and quickly produce more prototypes.

- Cost. Given a suitable geometry Metal Spinning can be a very cost effect way to produce large diameter hollow shapes.

Contact Be Cu Now for your Custom Metal Spinning, We are your best online Spinning services choice!

The Advantage of Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

- Compared to the tools employed in alternative forming methods, metal spinning tools are typically 10% of the cost.

- The metal spinning process amounts to significantly shorter turnaround times – tools and spun components can be available within weeks rather than months.

- Metal spinning tools can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Metal spinning produces smooth, durable objects without seams or welds, for parts require feature superior strength and great aesthetics.

The Specifications of Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

| CNC Metal Spinning Capabilities | English Units | Metric Units |

|---|---|---|

| Max Part Length / Height | 48.0 in | 1,220 mm |

| Max Blank Size, Diameter | 49.0 in | 1,245 mm |

| Max Roller Force | 19 ton | 169 kN |

| Max Blank Thickness, Stainless Steel | 0.25 in | 6.3 mm |

| Max Blank Thickness, Steel | 0.31 in | 8 mm |

The Shapes Achieved Of Metal Spinning Parts

Simple shapes are easy to make in less time. But for complex shapes, it requires more time because it increases steps as per the block shape.

In addition to metal spinning, Be-cu.com also offers in-house tooling, welding, abrasive polishing and hydroforming, helping to drive down your costs and streamline production. Quicker turnaround times and lower costs are two of the most attractive advantages of metal spinning. The ability to form very thick components and large diameters with uniformity and high quality at low and high quantities, are more appealing reasons to consider metal spinning.To find out if metal spinning would be beneficial for your application or end product, contact us today.

- Domed

- Flanged

- Domed with flange

- Dished

- Semi elliptical

- Hemisphere

- Flanged, dished and flued

- Trumpet

The Detail Of BE-CU Metal Spinning Company

At Be-cu.com, we use a variety of materials for metal spinning such as cold rolled steel, hot rolled steel, aluminum spinning, stainless steel spinning, brass, copper spinning and exotic metals such as titanium and inconel. Be-cu Metal Spinning Section specializes in the forming of stainless steel. With our automated metal spinning lathes and the capabilities of our deep drawing, stamping and welding equipment, our ability to form your part to your specifications and within your budget are realistic. Be-cu Metal Spun Company has over 30 years of metal forming experience and has used the spinning technology for a variety of industries such as aerospace, automotive, military, ordnance, plastics, lighting, pharmaceuticals, dairy, etc…

We have engineers on staff with metal spinning expertise to help guide you on designing a custom part and choose the optimal process to produce high quality spun parts at a competitive and affordable price. Tooling is custom made to form parts to your configuration.