CNC Drilling

- Global delivery as fast as 30 days

- Machined prototypes in as fast as 9 days.

- 100+metals and plastics

- Tolerances down to +-0.05mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

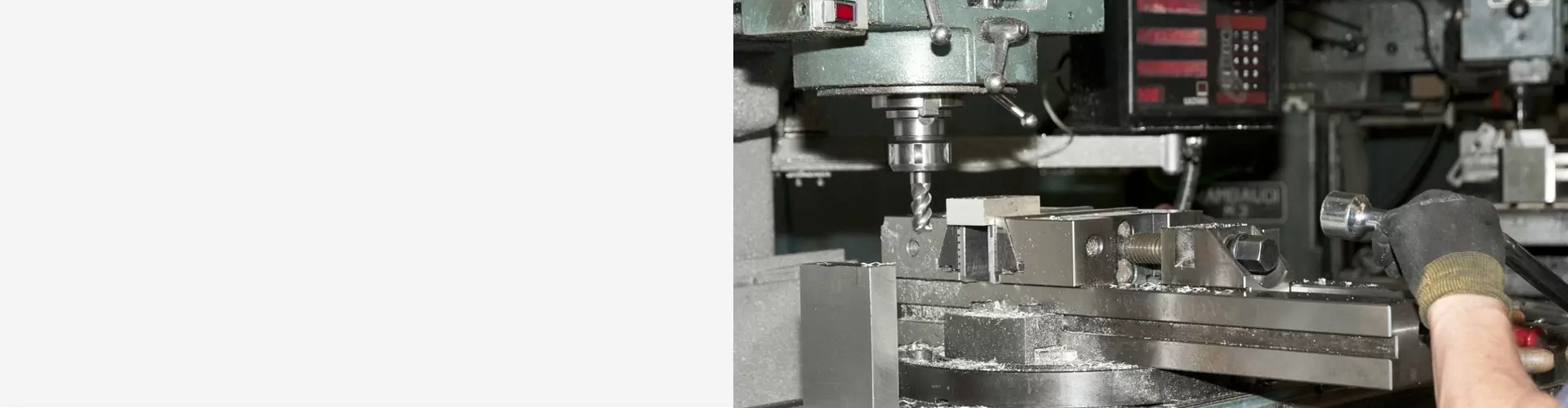

Drilling Define & How CNC Drilling Works

Drilling holes in solid materials with a drill is called drilling. The hole processing of various parts is completed by the fitters using drilling machines and drilling tools (drills, reaming drills, reamers, etc.) When drilling on a drilling machine, in general, the drill bit should complete two movements at the same time; the main movement, that is, the rotational movement of the drill bit around the axis (cutting movement); the auxiliary movement, that is, the linear movement of the drill bit against the workpiece along the axis direction ( Feed movement), when drilling, mainly due to the shortcomings of the drill bit structure, affecting the processing quality, the processing accuracy is generally below IT10 level, and the surface roughness is about Ra12.5μm, which is rough processing.Drilling centers are mainly used for the processing of small and medium-sized parts in the electrical and mechanical industries. It is a numerically controlled drilling-based hole machining machine. Due to the development of machining centers, most CNC drilling machines have been replaced by machining centers. In the automobile, locomotive, shipbuilding, aerospace, construction machinery industries; especially for super-long laminates, the drilling of large parts such as longitudinal beams, structural steel, and tubular parts is the first choice.When in use, the step-by-step process for CNC drilling includes:

- The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

- The operator installs the appropriate drill bit and secures the designated material on the table.

- The operator starts the drilling process through the control panel or interface.

- The spindle lowers, drilling the appropriate hole sizes and diameters.

In addition, on the basis of the three-coordinate CNC vertical drilling machine, a turret-type tool magazine and an automatic tool-changing mechanism can be added to form a drilling machining center (drilling center). The drilling center can not only perform drilling, expanding, reaming, countersinking, tapping and other hole processing procedures, but also can complete contour-controlled milling with linear and circular interpolation.

CNC Drilling Services For Precision Machine Parts – China Drilling Parts Manufacturer

Be-cu provides best CNC drilling services for the fabrication of both small and large series of parts of any complexity. We use various types of CNC drilling machines including upright, bench, radial, which allows us to drill holes of both simple and complex patterns up to 7 cm in diameter. The CNC drilling parts be made of metals and alloys (aluminium, steel, copper and others) and polymers. Our drilling services provide us with the capability to complete your job in-house to our exacting quality standards. Our advanced CNC drilling equipment is integrated with our machining centers and allows us to efficiently and precisely drill your part, whether you require simple or complex drilling patterns. Our drilling services offer precision machining for complex shapes that meet all your requirements.

CNC Drilling Accuracy

The precision offered by CNC is unmatched. It has provided companies in all industries with many returns, including raised productivity, lowered expenses and optimized production lines.

CNC Drilling Versatility

The precision offered by CNC is unmatched. It has provided companies in all industries with many returns, including raised productivity, lowered expenses and optimized production lines.

CNC Drilling Reproducibility

A continuous challenge for companies across markets is producing identical batches of products. This hurdle becomes amplified for custom machining projects. With CNC, however, those challenges are solved, leading to a consistent, imperfection-free production line.

CNC Drilling Applications – What is CNC Drilling Used for

Because the CNC drilling allows a very high precision without altering the structure of the material with a good rate of manufacture, CNC drilling is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our CNC drilling service is used to produce a variety of custom-designed CNC drilling parts and products in all areas of the industry:

The Case Studies Of CNC Drilling Parts

You have a complex part design, Our CNC drilling service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

5 Axis Cnc Machining Titanium Motorcycle Frame

-

5-axis Machining Aluminum 7075 Complex Special-Shaped Parts

-

5 Axis CNC Milling Aluminum 6061 Led High Bay Lighting Parts

-

5 Axis CNC Milling Aluminum Automotive Motor Enclosure

-

5-axis Machining Aluminum Alloy Motorcycle Gasoline Tank Housing

-

5 Axis Milling Machining Car Tail Light Housing

-

5 Axis Machining Automation Equipment Precision Parts

-

DMU Five-Axis Cnc Machining Aluminum Alloy Complex Structures Parts

-

Precision 5 Axis Machining Aluminum 6061 Aerospace Parts

-

Vertical 5 Axis Machining Complex Stainless Steel Parts