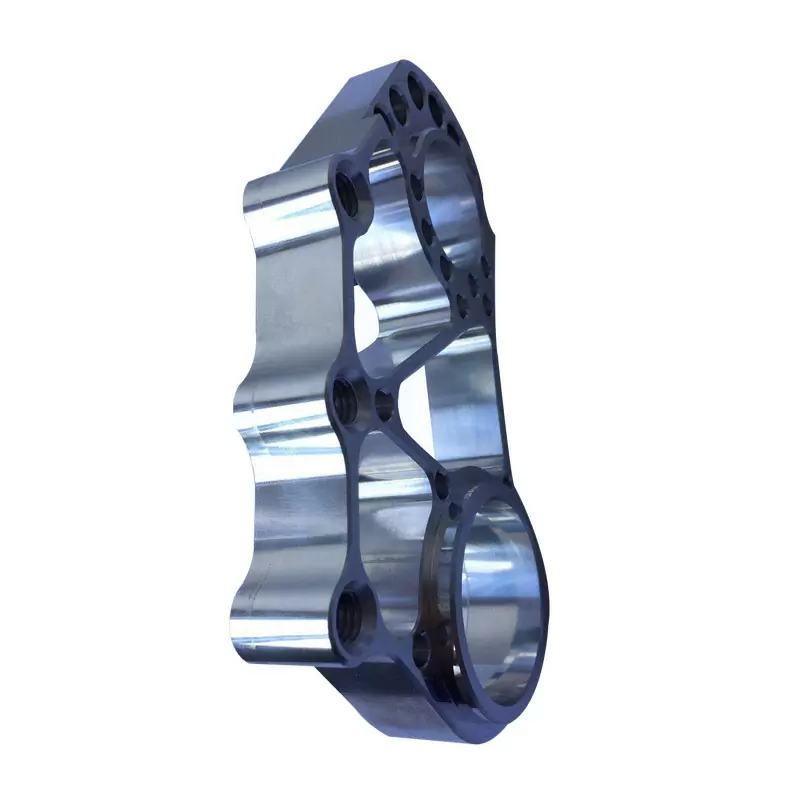

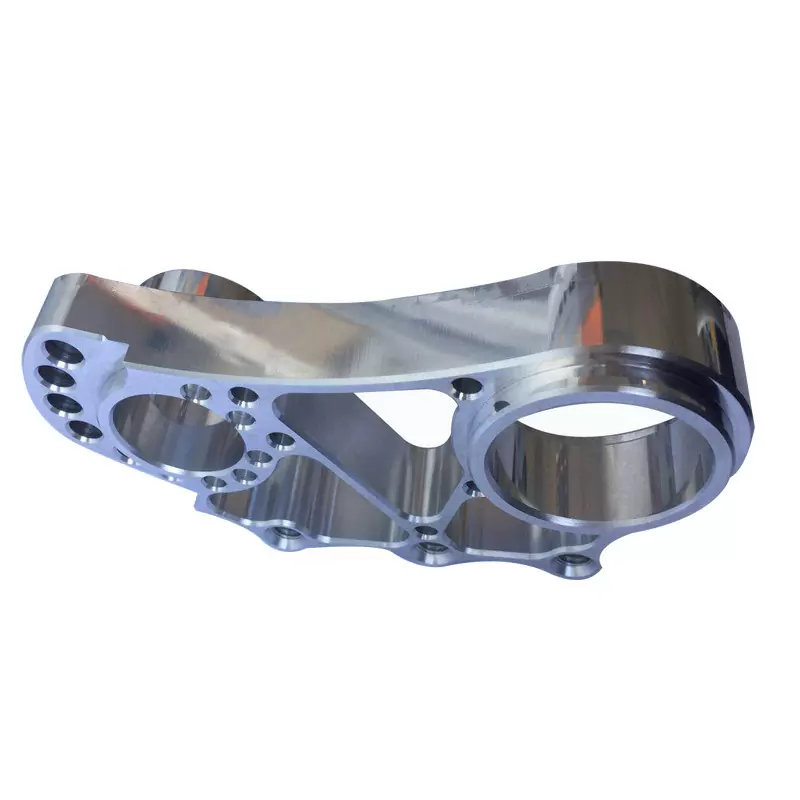

Custom Motorcycle Frame

- Product Name: Titanium Motorcycle Frame

- No+Color:Custom

- Surface Treatment:Oxidation

- Product Material: Titanium Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Titanium 5 Axis Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Motorcycle Parts

- Production Process:Cnc Machining

- Size: According To Customer’s Drawings

High-Quality 5 Axis Cnc Machining Titanium Motorcycle Frame

An excellent athlete, in addition to having an energetic heart, also needs strong bones and strong muscles to support it. The same is true for motorcycles, which must have an excellent frame to drive a high-performance engine.

- ★ Basic structure: Double beams span the engine, from the steering head to the front end of the rear rocker arm. The double beam design should be as short as possible to obtain stronger rigidity.

- ★ Advantages: high strength and high rigidity.

- ★ Purpose: Mainly used in sports cars such as super sports cars.

The frame is also a new design, the goal is to obtain precise and refreshing control response. For the surging four-cylinder side by side, our customer optimized the aluminum alloy double-beam frame and hugged the engine as a strengthening unit through 4 points; the titanium alloy rear rocker arm with the upper truss structure has unusual strength, To drive 200 horsepower; the sub-frame is made of magnesium alloy, with the goal of high strength and light weight.

This group of connecting rods made of special processing technology is made of all-titanium alloy, which is the first use in mass-produced motorcycles! Compared with the traditional steel connecting rod, the weight is reduced by 40%, which greatly reduces the inertia! At the same time, the newly designed crankshaft is also reduced by 20%, which makes the engine response very sensitive, especially in the high-speed region, which is very competitive! In addition, the exhaust system with a 4-2-1 structure is also cnc milling titanium alloy material, while the rims are made of magnesium alloy, which reduces the mass of the front and rear rims by 4% and 11%, respectively, and accelerates and brakes more. Handy. These lightweight and high-strength materials reduce the weight of the motorcycle to 179kg, even if the fuel tank is filled with gasoline, the weight does not exceed 200kg.

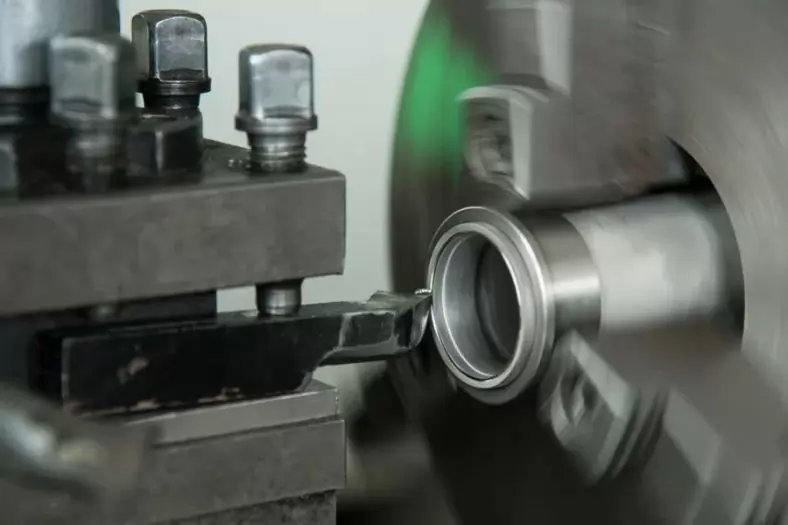

BE-CU Rapid Prototyping Companies Supply 5 Axis Cnc Machining Titanium Motorcycle Frame services for the motorcycle parts applications. Capabilities include machining, turning, prototyping, 3 and 5-axis milling.

The Advantages Of 5 Axis Cnc Machining Titanium Motorcycle Frame

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of 5 Axis Cnc Machining Titanium Motorcycle Frame

| Material | Titanium Alloy/Magnesium Alloy |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Automotive,Motorcycle |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU 5 Axis cnc machining Company

As an experienced and professional machine shop specialized in CNC manufacturing for many years, BE-CU.COM is capable of precision 5 axis CNC machining services and 5 axis milling. Whether you are in need of high-quality and precise metal or plastic components, we can provide 5 axis machining parts to worldwide clients for a variety of industries including automotive, medical, military, aerospace, mechanical, machine tool, high-tech, and more, with excellent machining and programming skills, as well as 5 axis CNC machining center. No matter how complex the CNC machining parts, each step will be executed with a rigorous attitude, to deliver exceptional 5 axis machining components that demonstrate the highest quality standards. Even though any problems during the process, we’ll keep running the job and make adjustments until all the issues are addressed.If you require a well-established and cost-effective CNC machining company to take over your project, BE-CU can achieve your expectation.

-

5 Axis CNC Machining Medical Olecranon Plate

-

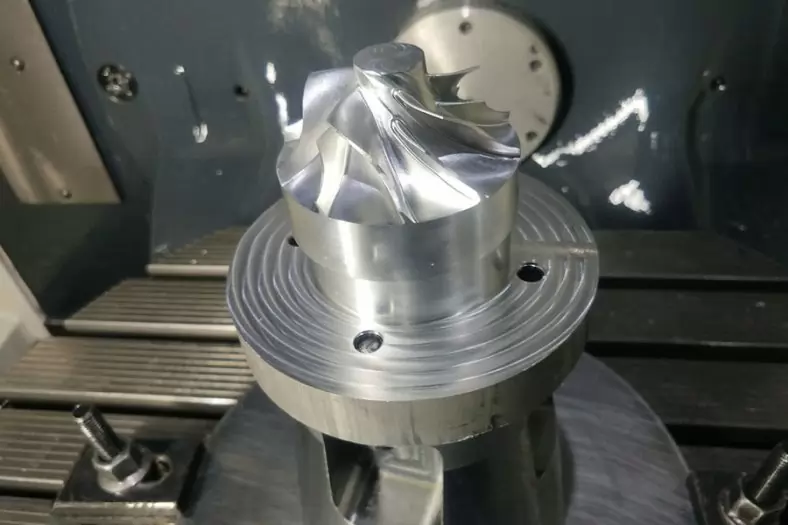

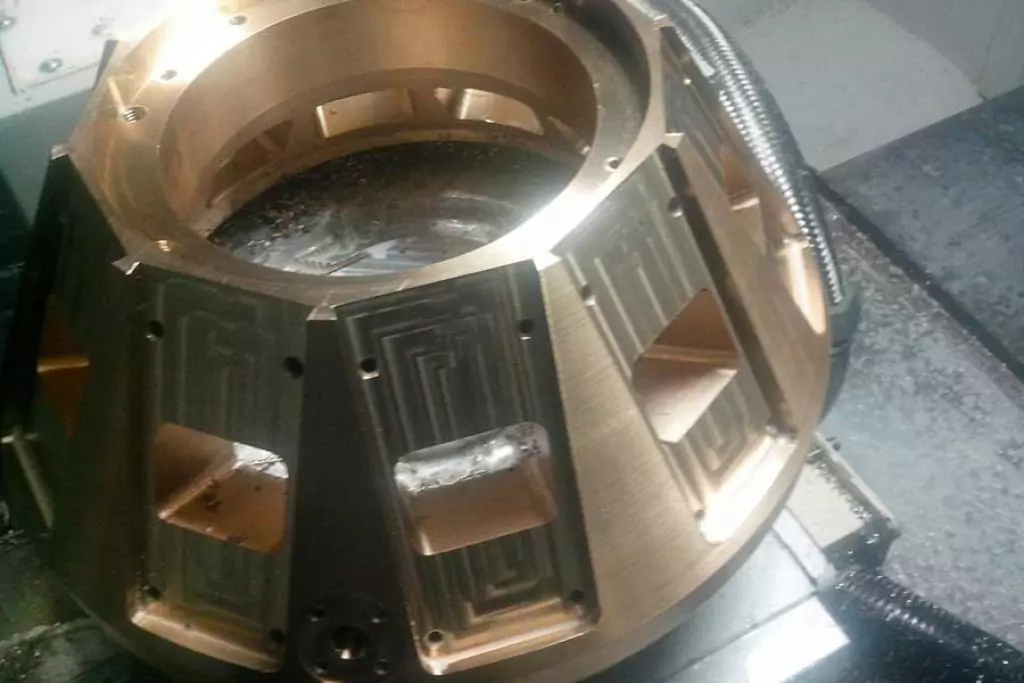

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

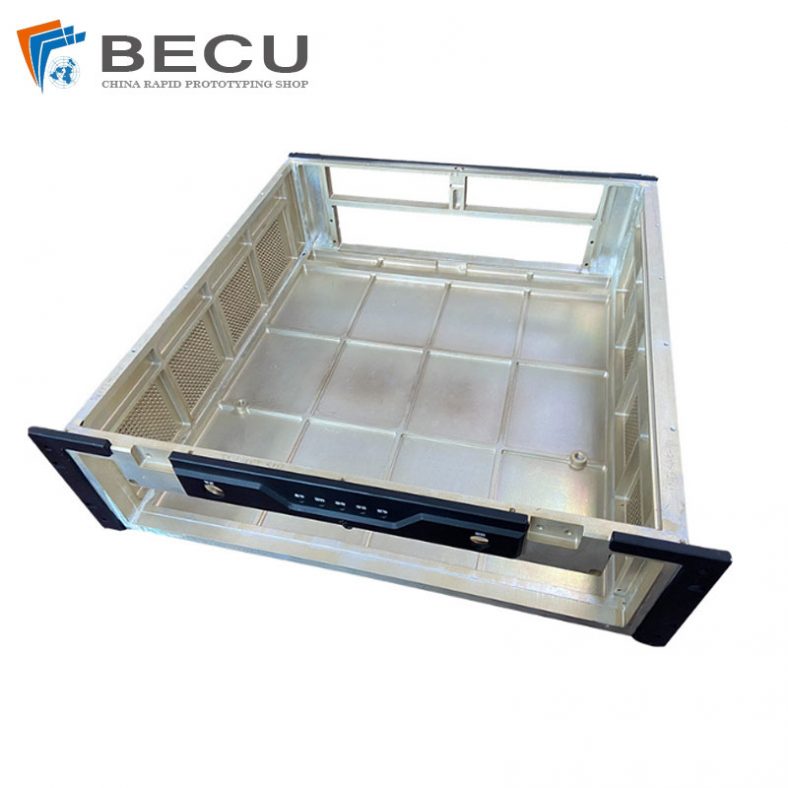

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

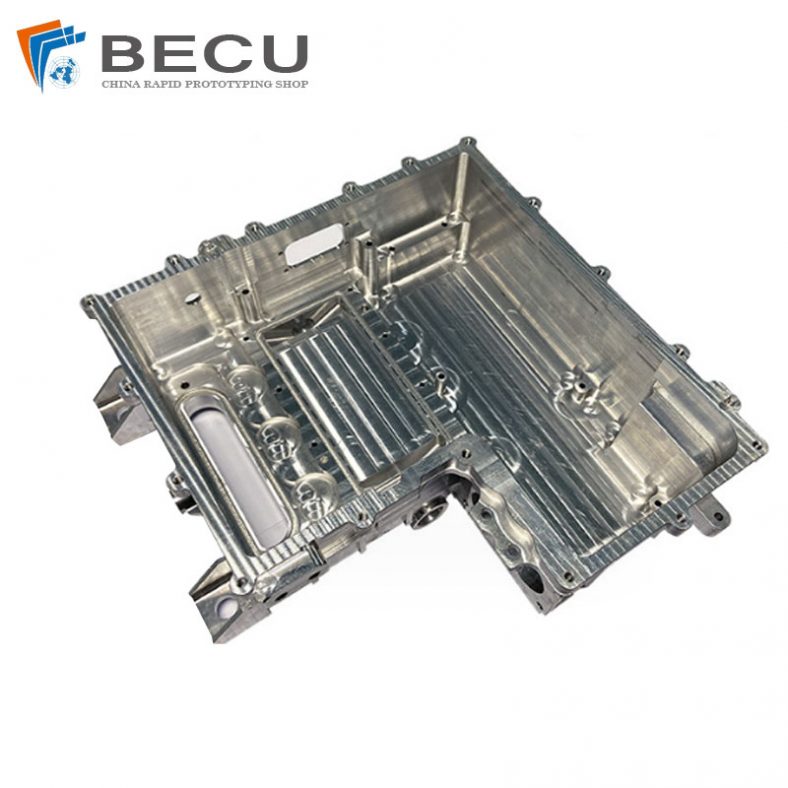

CNC 6063 Aluminum Automotive Motor End Cover

-

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining