CNC Milling

- Global delivery as fast as 10 days,Machined prototypes in as fast as 1 days.

- 100+metals and plastics

- Tolerances down to +-0.001mm

- ISO 9001:2015, ITAF 16949

- 3-, 4-, & 5-AXIS Milling.True 5-axis milling, 3+2,Mazak Turn+Mill Machine

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Precision CNC Milling Services – China Top CNC Milled Parts Manufacturer

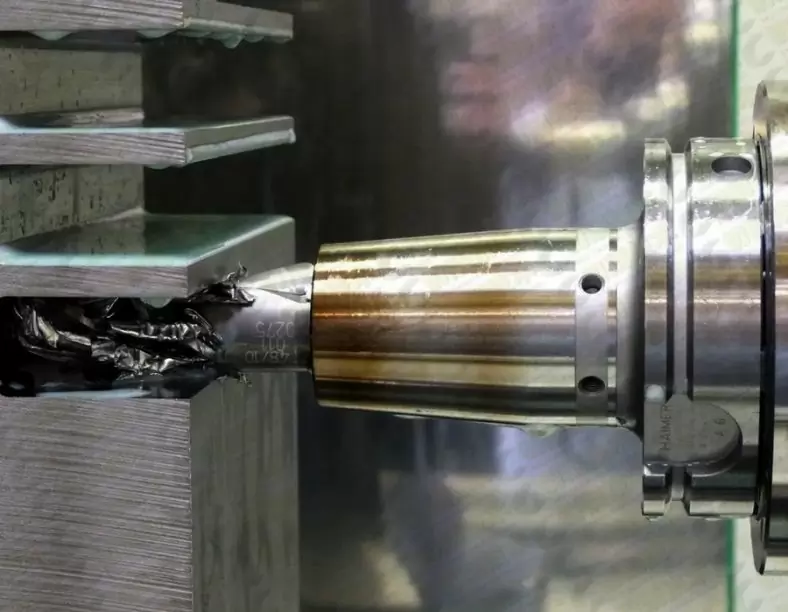

Looking for high quality metal or plastic parts cnc milled by an experienced and reliable components manufacturer? As one of the leading cnc milling services companies in China, Be-cu can provide you with the best cheap cnc milling parts whether you are looking for Angular Milling,Gear Milling, Straddle Milling, Thread Milling or Profile Milling. We provide one-stop customized cnc milling parts with competitive prices to the global marketplace, plus a multitude of related services, including engineering, designing, machining, finishing and assembly. Enable to process the cnc milling parts with stable and reliable quality according to customers’ specifications. We own advanced techniques, professional engineering team and cnc machine to ensure that the cnc milling parts meet your requirements and achieve the demands for precision and productivity. Our cnc milling builder will manufacture the appropriate precision parts for you for cnc machining center with up to Ø 300. PTJ Group(Be-cu’s Parent Company) has been china leader in providing cnc milling services for decades now. From our humble beginnings in 1995 to our now ever expanding and adapting company we have provided nothing but the best work for our customers.

Why Choose Be-cu CNC Milling Services

- With decades of experiences and expertise in CNC machining services, we providing OEM milling service and products involving precision milling, thread milling, metal milling, plastic milling, etc.

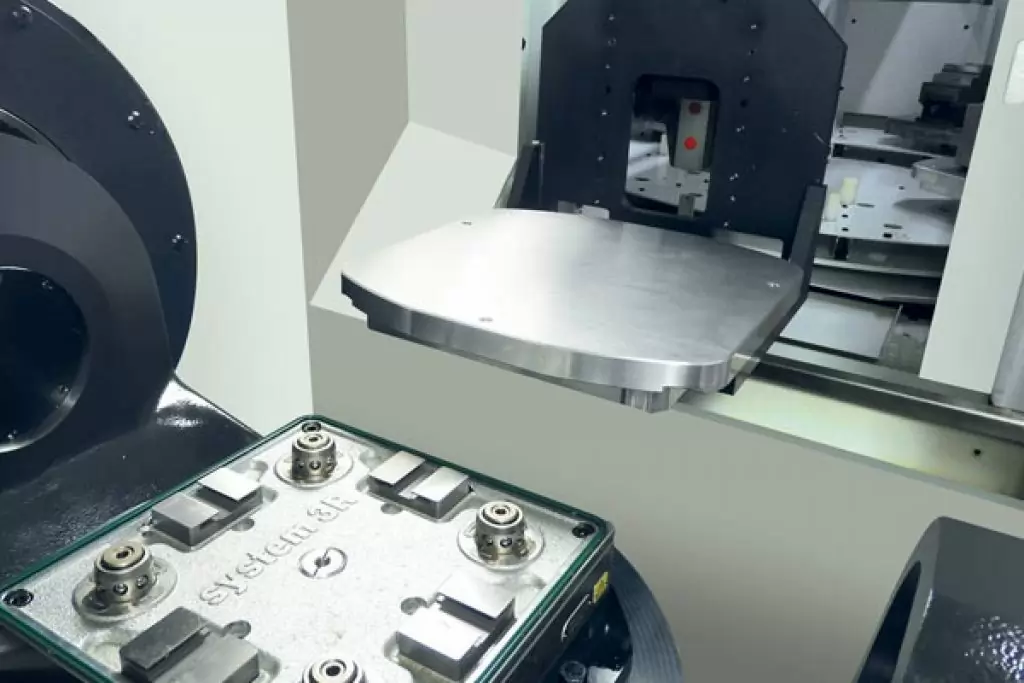

- 70 advanced CNC machines at the Be-cu CNC Milling Center:80% of aspect and mechanical parts can be CNC milled within minutes or even seconds by optimizing the tool paths and using special cutting tools. With automation set up, CNC milling is super cost-efficient for mass production comparing with additive manufacturing in most of the cases.

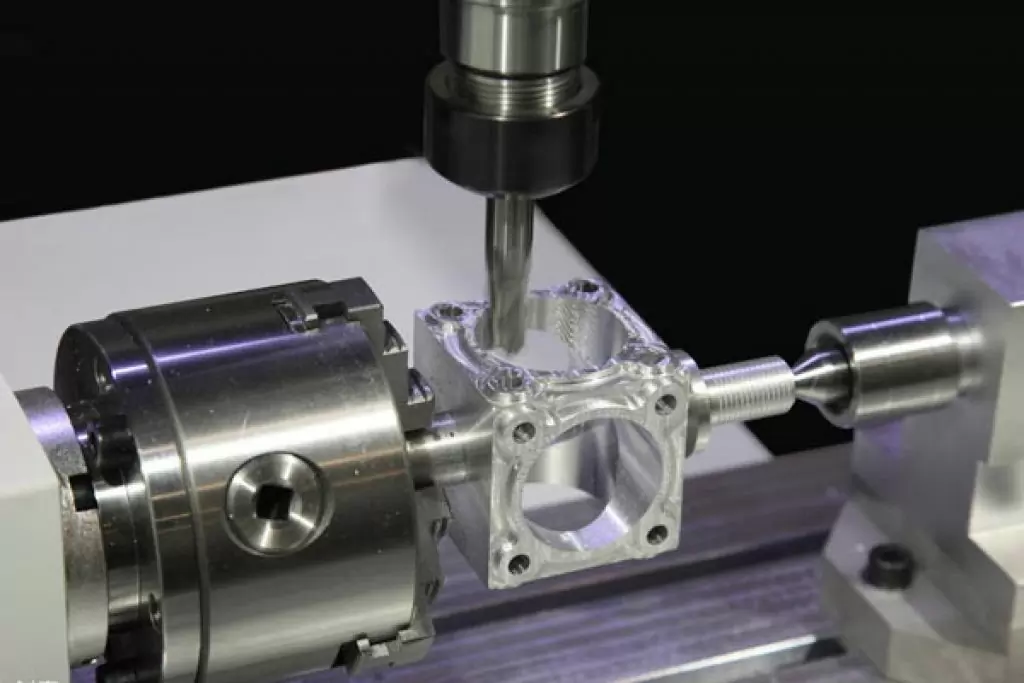

- Because the cutting tool of a milling machine can approach the workpiece from several different angles, it is possible to create complex shapes CNC parts, with more axis, we can create parts of greater complexity. If a CNC project demands an irregular shape, milling is often the best bet.

- High Precision Production. Be-cu custom CNC milling parts in tolerances ranging from +/-0.001″ – 0.005″, custom design depending on customer specs

- Extensive Material Option. Mainly metal Milling Material Include Cnc Milling Aluminum,Cnc Milling Brass,Cnc Milling Stainless Steel,Cnc Milling Copper,Cnc Milling Titanium And More

Our CNC Milling Capabilities

We offer CNC milling service for any types of custom CNC parts, whatever plastics or metals, simple or complex. With our precision 3-, 4- and 5-axis CNC milling centers, combined with other advanced capabilities and our experienced team, we can offer high-quality CNC parts as well as fast delivery.

3 Axis Cnc Milling

Standard CNC mills have 3 axes, allowing the spindle (and attached cutting tool) to travel along the X, Y and Z axes. If the cutting tool cannot reach an area of the part, the part must be removed and manually rotated.

4 Axis Cnc Milling

Some CNC mills incorporate an extra degree of movement by rotating on a vertical axis. This enables greater flexibility and the ability to create more complex parts.

3+2 Axis Cnc Milling

The two rotary axes first fix the cutting tool in an inclined position, and are then machined by the feed axes X, Y, Z. A rotational work plane in space can be defined by means of 3+2-axis cnc milling, such as a rotary head or rotary table.

5 Axis Cnc Milling

The most advanced type of widely used CNC mill is the 5-axis mill, which incorporates two extra degrees of movement, often by adding rotation to both the worktable and spindle. Parts usually don’t require multiple setups, since the mill can manipulate them into different positions.

- Be-cu can mill a precision and complex part from our 5 Axis milling machines with different types of tools and how we guarantee the quality by using on-machine inspection system.

- Our experienced engineers are able to select the right tools, optimize tool paths to cut fast and achieve good milling surface, as well as keeping tight tolerance. We can provide all types of custom CNC milled parts to meet your project needs.

- To enable you to further optimise your metal machining applications when milling and design them to be even more efficient, Our milling cutters that offer high productivity while delivering first-class, perfect results. Workpiece by workpiece. On any machine. For example when face and shoulder milling, slot milling and copy milling.

- Be-cu Cnc Milling Shop’s Capabilities offer you custom-made, parts solutions. Our Cnc Milling Line are made to achieve high-quality results cost-effectively. The cnc milling service from the be-cu impress when machining small and medium batches because these milling method are suitable for a wide range of applications and are compatible with various materials such as steel, stainless steel and aluminium. The our cnc milling service combine low costs with excellent performance data and a wide product range.

If you are having any problem to get your CNC milling parts done, contact us and try to get a solution from BE-CU.

CNC Milling Applications – What is CNC Milling Used for

Because the milling allows a very high precision without altering the structure of the material with a good rate of manufacture, CNC Milling is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our CNC Milling service is used to produce a variety of custom-designed CNC milling parts and products in all areas of the industry:

What Is Cnc Milling?-Cnc Milling Define

Cnc Milling is to fix the blank, and use a high-speed rotating milling cutter to run on the blank to cut out the required shapes and features. Traditional milling is mostly used to mill simple contour features such as contours and slots. CNC milling machines can process complex shapes and features. The milling and boring machining center can perform three-axis or multi-axis milling and boring processing for machining, molds, inspection tools, tire tools, thin-walled complex surfaces, artificial prostheses, blades, etc. When selecting CNC milling processing content, the advantages and key roles of CNC milling machines should be fully utilized.

Cnc Milling machines include horizontal milling machines or vertical milling machines, as well as large gantry milling machines. These machine tools can be ordinary machine tools or CNC machine tools. Cutting with a rotating milling cutter as a tool. Milling is generally carried out on a milling machine or a boring machine, and is suitable for cnc machining planes, grooves, various forming surfaces (such as splines, gears and threads) and special shapes of molds.

The Object Of Cnc Milling

- Plane Parts: The characteristics of plane parts are that the machined surface can be parallel to the horizontal plane, perpendicular to the horizontal plane, or can form a fixed angle with the horizontal plane; most of the parts processed on the CNC milling machine belong to the plane. Type parts, plane parts are the simplest type of parts in CNC milling, generally only need to use the two-axis linkage or three-axis linkage of the three-coordinate CNC milling machine to process. During the machining process, the machined surface is in surface contact with the tool, and end mills or bull nose cutters can be used for roughing and finishing.

- Surface Parts: The characteristics of surface parts are that the machined surface is a space surface. During the machining process, the machined surface and the milling cutter are always in point contact. Surface finishing is mostly carried out with ball-end milling cutters.

The Case Studies Of Cnc Milling Parts

You have a complex part design, Our Cnc Milling service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Precision CNC Machining Aluminum 7075 Spotlight Base

-

Custom Cnc Milling Machining Aluminum Alloy 2024 Parts

-

Five-Axis Precision Cnc Milling Machining IOT Robotic Parts

-

Five-Axis Precision Cnc Milling Automation Parts

-

4-Axis CNC Machining Aluminum 2011 Medical Parts

-

Aluminum 6063 Complex Robotic Parts By 5 Axis Cnc Machining

-

Precision 5 Axis Machining Aluminum 6061 Aerospace Parts

-

DMU Five-Axis Cnc Machining Aluminum Alloy Complex Structures Parts

-

5 Axis Machining Automation Equipment Precision Parts

-

5 Axis Milling Machining Car Tail Light Housing