MJF 3D Printing

- MAX PART SIZE:Custom

- LEAD TIMES:From 5 Working Days

- Tolerances of +/- 0.004” or +/- 0.05” per inch

- MIN PART SIZE:1 x 1 x 8 mm

- LAYER HEIGHT:100 microns

- MIN WALL THICKNESS:20~30μm

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

MJF 3D Printing Service – China Rapid Multi Jet Fusion Manufacturer

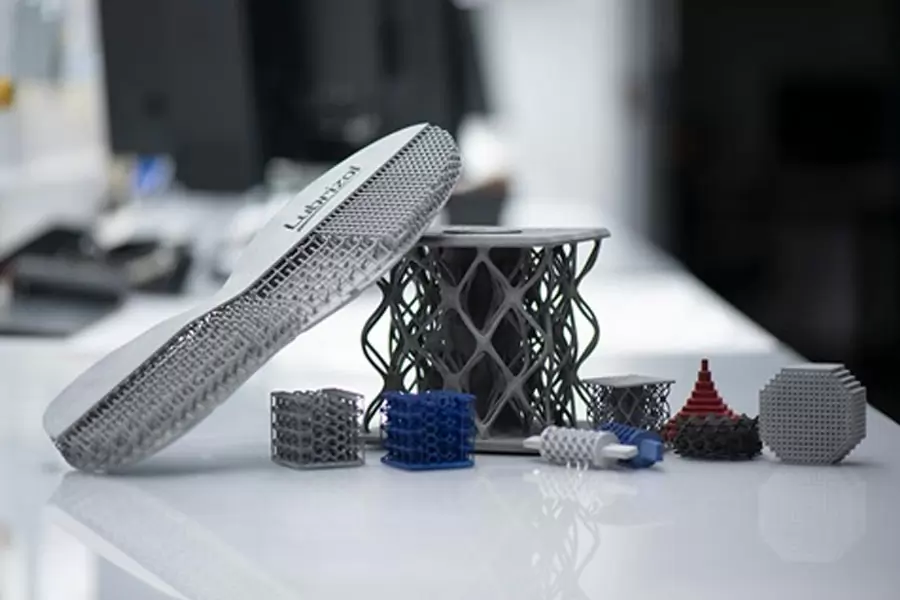

Multi Jet Fusion is an industrial 3D printing process that produces functional nylon prototypes and end-use production parts within 1 day. The final part has a high-quality surface finish, excellent feature resolution, and more consistent mechanical properties than processes such as selective laser sintering. The process simplifies workflow and reduces costs, enables rapid prototyping, realizes component manufacturing with breakthrough economics, lowers the threshold for use, and supports an open material and software innovation platform for new applications in various industries. The process simplifies workflow and reduces costs, enables rapid prototyping, enables component manufacturing with breakthrough economics, lowers barriers to use, and supports new applications in various industries. An open material and software innovation platform

From prototyping to small-batch production,Be-cu global network of certified MJF 3D printing facilities will allow you to produce highly accurate parts with quality and strength comparable to injection molding.Our expertise in additive manufacturing, high-end functional testing prototypes, 24 hours services, competitive price, on time delivery drop- shipping to over 150 countries to help you transform your ideas into projects, bring your innovative products to market faster, reduce your production costs, save your research and development time.Upload your CAD files, receive an instant Multi Jet Fusion 3D printing quote and get your parts into production in less than 5 minutes.

Metal finishing service is a essential choice to achieve your design perfectly. Be-cu is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide MJF 3D Printing service and a wide range of surface treatment services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. Here are the introductions to different types of metal finishes, more details please feel free to contact us.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

Why Choose Be-cu MJF 3D Printing Service

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

How Does MJF 3D Printing Work? – Steps of MJF 3D Printing Process

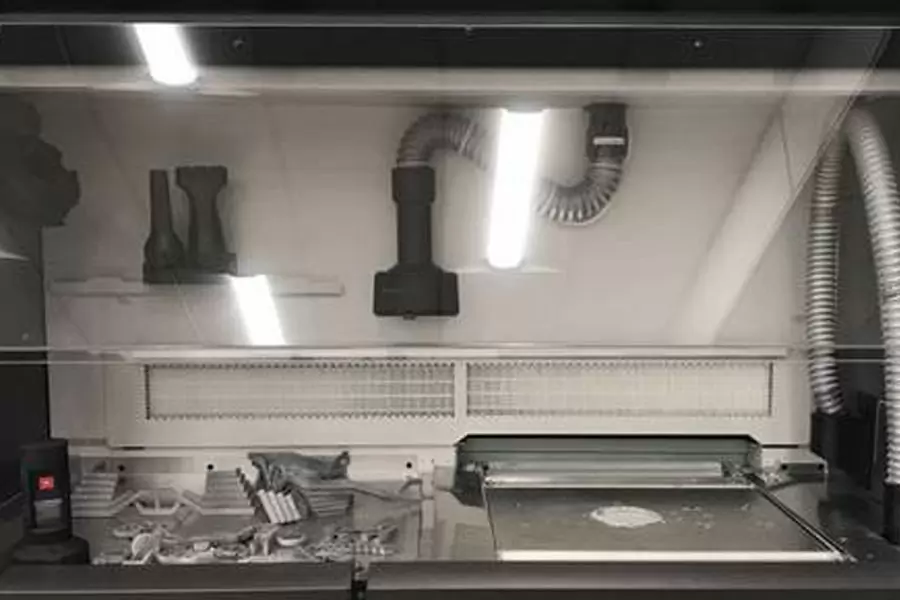

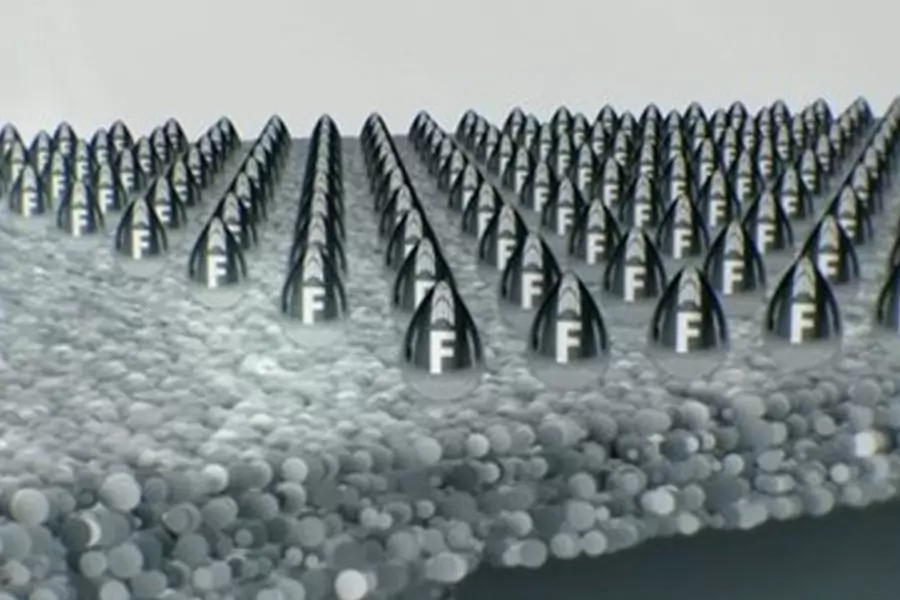

Multi Jet Fusion uses an inkjet array to selectively apply fixer and refiner on a bed of nylon powder, which is then melted into a solid layer by a heating element.

After each layer, the powder is dispensed onto the top of the bed, and the process is repeated until the part is complete. Once built, the entire powder bed with encapsulated components is moved to a processing station where most of the loose powder is removed by an integrated vacuum.

The parts are then sandblasted to remove any remaining residual powder before eventually reaching the finishing department where they are dyed black to improve their appearance.

If you are having any problem to get your DLP 3D printing parts done, contact us and try to get a solution from BE-CU.

MJF 3D Printing Applications – What is MJF 3D Printing Used for

China Top MJF 3D Printing Supplier & Manufacturer – Be-cu offers worldwide clients affordable, rapid, high precision custom MJF 3D Printing Services, variety of materials available to meet the needs of different industries!

The Case Studies Of MJF 3D Printing Parts

You have a complex part design, Our MJF 3D printing service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

MJF 3D Printing Nylon 12 Prototype Parts

-

MJF 3D Printing Handicraft Prototype

-

MJF 3D Printing Nylon 12 For Industrial Parts

-

Multi Jet Fusion Printed Nylon Plastic Parts

-

MJF 3D Printing Bicycle Honeycomb Saddle

-

MJF 3D Printing Black Nylon Medical Arm Guards

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

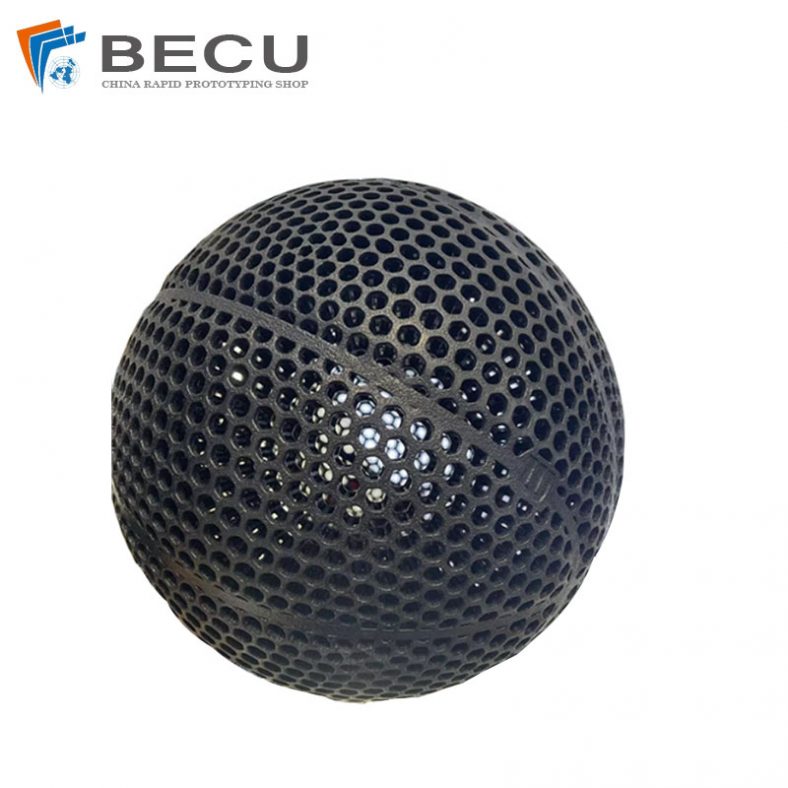

Nylon 3D Printed Size 5 Basketball

-

3D Printing Pool Pressure Cleaner Parts and Accessories