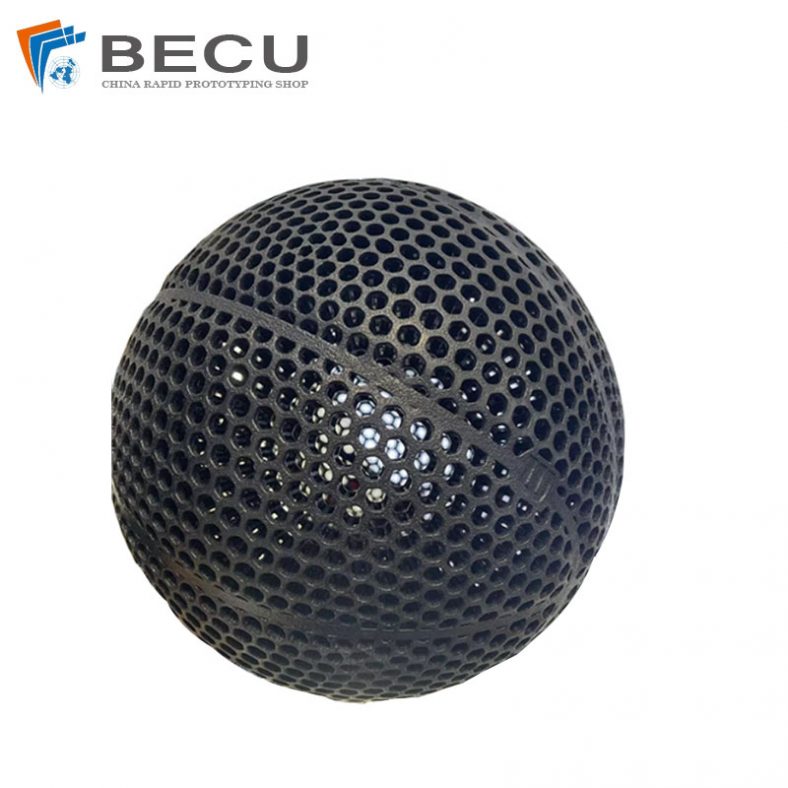

Bicycle Honeycomb Saddle

- Product name: Nylon 12 Honeycomb Saddle

- No+Color:Custom

- Surface treatment: Custom

- Product material: Nylon Material

- Proofing cycle:7 days(100000 pcs/M)

- Machining Factory:BE-CU.com

- Production Process: MJF 3D Printing

- Size:According To Customer Drawings

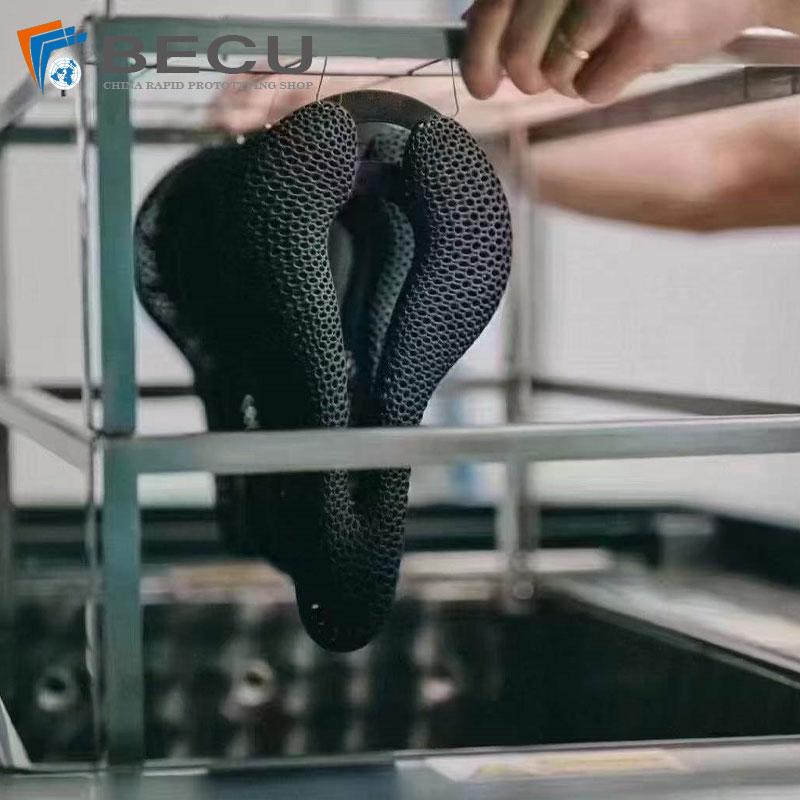

High-Quality MJF 3D Printing Bicycle Honeycomb Saddle

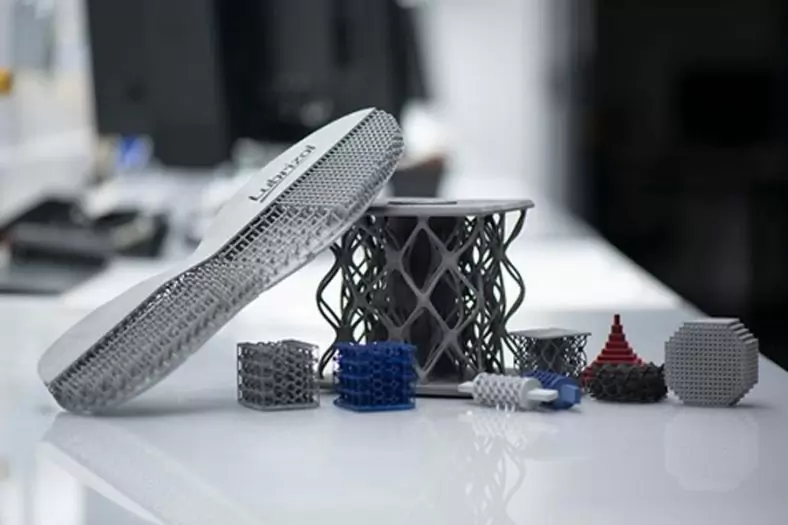

The world of cycling is constantly evolving, with manufacturers continuously exploring innovative technologies to enhance rider experience and performance. Among these advancements, MJF (Multi Jet Fusion) 3D printing has emerged as a game-changer in the bicycle industry. By utilizing MJF technology to create bicycle saddles with honeycomb structures, Be-Cu China 3D Printing manufacturers can now offer cyclists unparalleled comfort, weight savings, and customized designs.

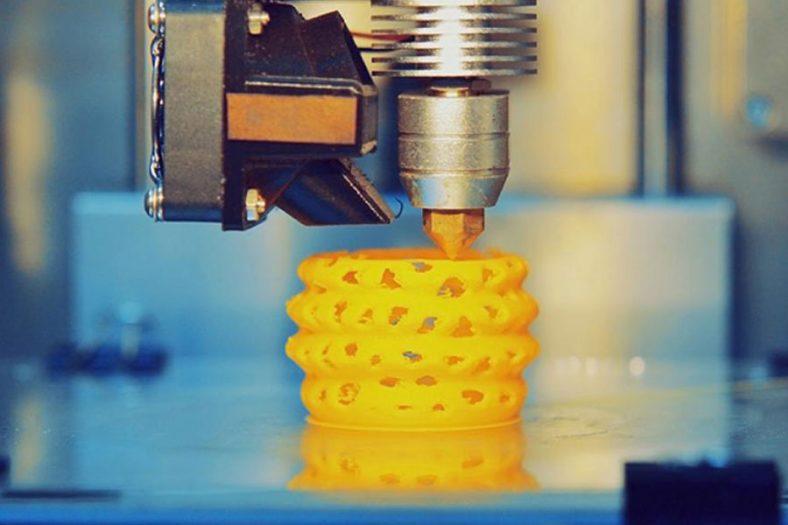

Understanding MJF 3D Printing Technology

MJF 3D printing is an additive manufacturing process that utilizes thermoplastics to create three-dimensional objects. It involves selectively fusing powdered material layer by layer using a combination of infrared heating and high-resolution inkjet printing. This process allows for intricate geometries and lightweight structures, making it ideal for producing bicycle components such as saddles.

The Advantages of Honeycomb Structures

Honeycomb structures, inspired by nature, consist of hexagonal cells with exceptional strength-to-weight ratios. We explore the biomechanics behind honeycomb designs and how they translate to enhanced comfort and performance in bicycle saddles. The ability to create custom lattice densities and patterns using MJF technology opens new possibilities for optimizing saddle characteristics for individual cyclists.

Enhanced Comfort and Pressure Distribution

Traditional bicycle saddles often lead to discomfort and pressure points for riders, especially during long rides. MJF 3D printed honeycomb saddles provide a unique solution by offering superior shock absorption and even weight distribution. We analyze the benefits of this innovative design in reducing discomfort and enhancing the overall riding experience.

Lightweight Design and Performance Gains

Weight plays a critical role in cycling performance, especially in competitive scenarios. The lightweight nature of MJF 3D printed honeycomb saddles allows cyclists to achieve significant weight savings compared to conventional saddles. We discuss how reduced saddle weight contributes to increased speed, acceleration, and maneuverability.

Customization and Ergonomics

Each cyclist has unique anatomy and preferences when it comes to saddle design. MJF 3D printing enables the creation of fully customizable saddles, tailoring the lattice density, shape, and cushioning to suit individual riders. We delve into how personalized saddles can optimize comfort and performance while reducing the risk of injuries.

Material Selection for MJF 3D Printed Saddles

Choosing the right materials is crucial for ensuring the durability and performance of MJF 3D printed saddles. We explore the various thermoplastic materials commonly used in MJF 3D printing and their suitability for bicycle saddle applications.

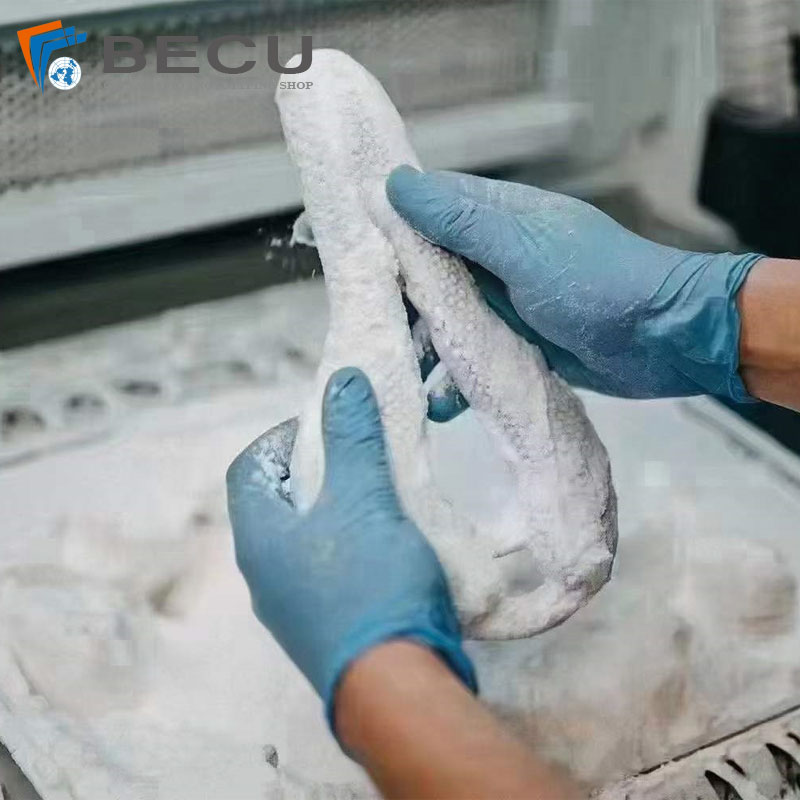

Overcoming Challenges in MJF 3D Printing

As with any emerging technology, MJF 3D printing for bicycle saddles presents certain challenges. From design optimization to post-processing considerations, we discuss the obstacles manufacturers face and the ongoing efforts to refine the process.

Environmental Sustainability

With the growing emphasis on sustainability in the cycling industry, we examine the environmental benefits of MJF 3D printing in terms of reduced material waste and energy consumption compared to traditional manufacturing methods.

MJF 3D printing is revolutionizing the world of cycling by offering unparalleled comfort, performance, and customization in bicycle honeycomb saddles. With the ability to create lightweight, durable, and individualized designs, this innovative technology is poised to shape the future of cycling components. As manufacturers continue to explore new materials and optimize the MJF 3D printing process, cyclists can look forward to an era of unprecedented riding comfort and enhanced performance on two wheels.

Why Choose MJF 3D Printing Bicycle Honeycomb Saddle Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

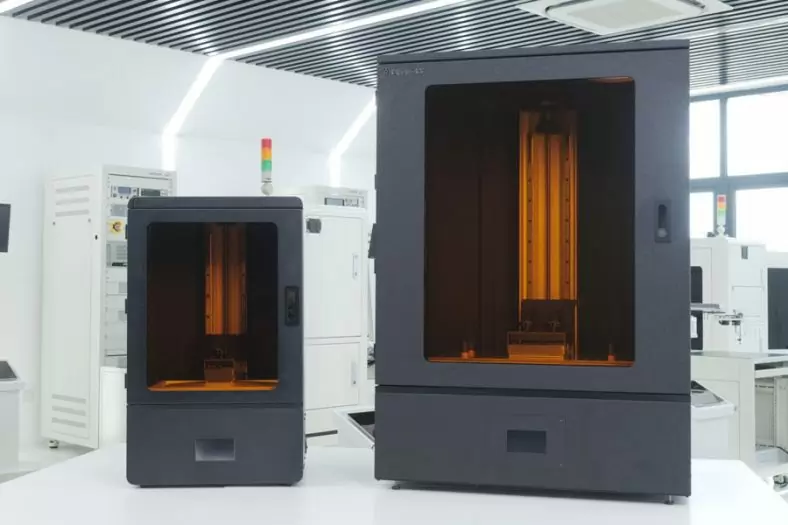

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of MJF 3D Printing Bicycle Honeycomb Saddle

| Item Name | 3D Printing |

| Material | thermoplastics, polycarbonate, ASA, nylon12 CF and Ultem resin etc |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.