What Is Magnesium And Alloy

Magnesium alloys are metal alloys composed primarily of magnesium along with other elements. These alloys are created by combining magnesium with various alloying elements, such as aluminum, zinc, manganese, and rare earth metals. Magnesium alloys are the lightest structural metals with a high strength-to-weight ratio.The addition of these elements imparts specific properties and characteristics to the magnesium, enhancing its strength, corrosion resistance, and other desirable qualities.

Corrosion and mechanical properties have many characteristics: fast heat dissipation, light weight, good rigidity, certain corrosion resistance and dimensional stability, impact resistance, wear resistance, good attenuation performance and easy recycling; in addition, it also has thermal conductivity and High conductivity, non-magnetic, good shielding, non-toxic and so on.

How Hard Is It To Machining Magnesium Alloy?

While magnesium provides many benefits, it is also a difficult alloy to machine.Machining Magnesium alloy can present certain challenges compared to other materials. While it is not necessarily extremely difficult, it requires specific considerations due to the properties of magnesium and its alloys. Here are some factors that make machining magnesium unique:

Flammability

Heat Dissipation

Low Cutting Forces

Chip Control

Tool Selection

Corrosion Concerns

Machining magnusium alloy materials involves selecting the right equipment, with the right partner who can customize, deploy and support your manufacturing and purchasing strategies. With BE-CU, you’ll not only get one-stop metal cnc machining service and you’ll receive the support and solve all your doubts about machining & production.

Can You CNC Magnesium?

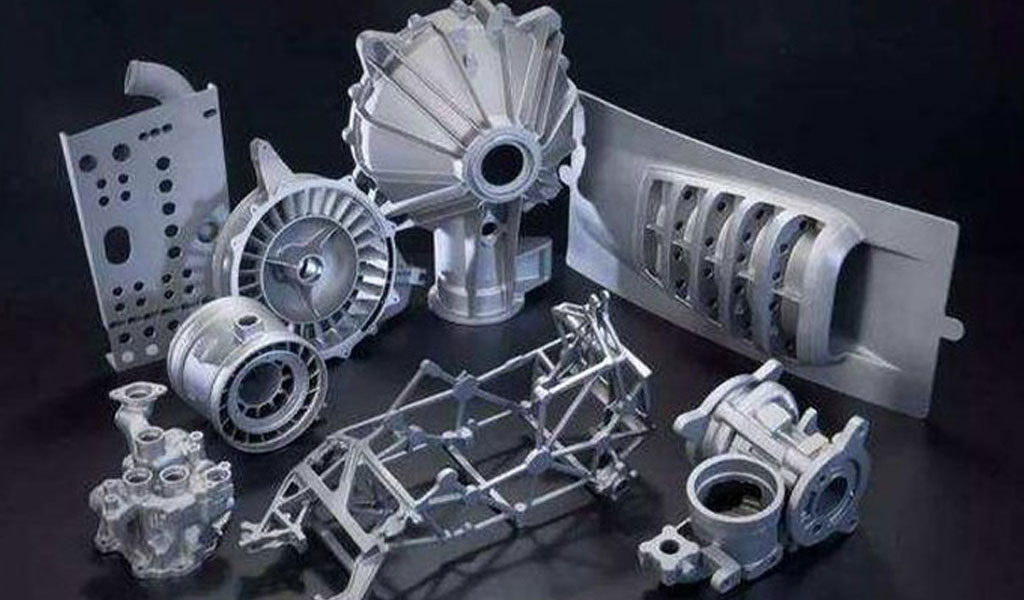

Yes!Magnesium alloys are lightweight and possess excellent strength-to-weight ratios, making them suitable for various applications, such as aerospace components, automotive parts,electronic devices,new energy parts, pharmaceutical and chemical industry, photographic equipment, audio equipment, 3C products, robots and other fields..

CNC machining is often employed to shape and manufacture these magnesium alloy components with high accuracy and repeatability.

When innovative industries choose to pioneer in the use of magnesium alloys, they call Be-Cu prototype for a very traditional outcome: a consistently reliable supply of top quality magnesium machined components.Be-Cu prototype has a reputation for successfully machining the metals other producers prefer not to handle. Customers can confidently design with new materials, secure in the knowledge that Be-Cu prototype can machine even the most difficult, magnesium alloy for a quality, cost effective result.

Cnc Machining Magnesium – Machining Magnesium Service

China Be-Cu Prototype specializes in the research and development of Magnesium CNC machining. Be-Cu has long-term cooperation with research institutes and enterprises in automobile, China aviation, aerospace, shipbuilding and special industries;

Capabilities of CNC machining, vacuum brazing, vacuum electron beam welding, vacuum diffusion welding, and various high-end surface treatments involved in the product manufacturing and production process, and strictly follows the ITAF 16949 system, from raw materials to entry inspection, Process monitoring, quality information management, and quality prevention are four dimensions.

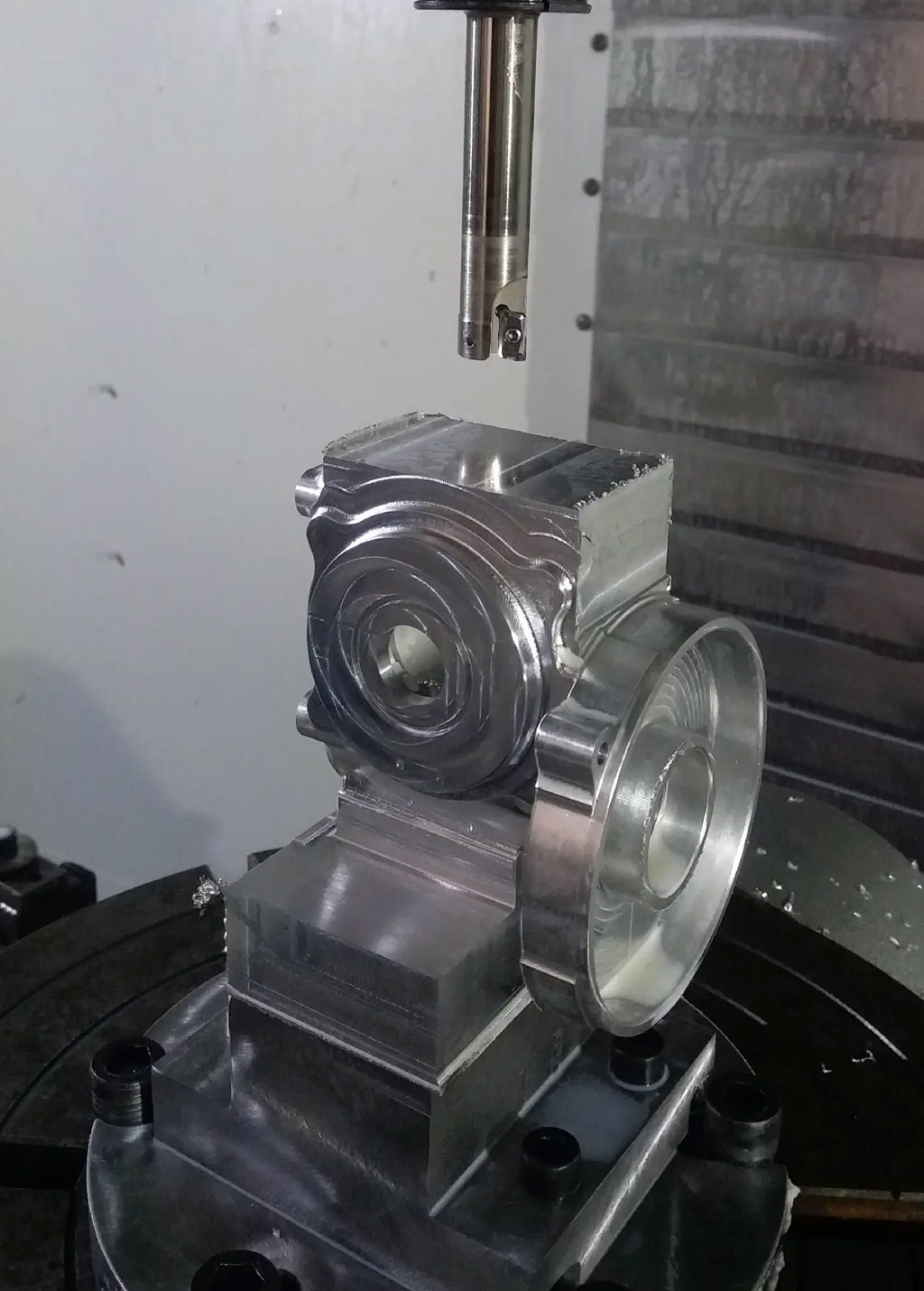

Machining custom components from difficult-to-machine magnesium alloys materials requires advanced machining capabilities. Be-Cu utilizes the latest in 3-axis, 4-axis, and 5-axis machining technologies in order to form your specific components from the most durable, reliable metals available.

We work extensively with magnesium alloy blocks to provide high-performance machined parts, tight tolerances and critical surface finishes. Our ISO 9001:2015 certified machining process ensure that your machined parts designed and manufactured to the highest industry standards.

Request a quote or email us at [email protected] and start your magnesium machining project today.

Common Used CNC Magnesium Alloy Material Type

With years of machining mission-critical magnesium components, Be-Cu has accumulated the knowledge and expertise needed to reliably produce high-quality magnesium machined parts. Throughout our tenure as a precision CNC machining shop, we have developed a reliable, cost-effective magnesium material supply chain to ensure our customers receive the best possible value. Magnesium material grade we have common used includes:

Besides,Be-Cu also has the capabilities to machine magnesium alloy in the form of die castings.Work with the magnesium machining experts at BE-CU.COM.

Why Choose Our Magnesium Cnc Machining Service?

- Save time and money for your magnesium project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of magnesium grades and alloy materials can be machined

- Custom complex magnesium machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Magnesium Alloy Material Chart Of Cnc Machining

| Grade | Tensile Strength | Elongation at Break | Yield Point | Density | Maximum Temperature | Tensile Modulus |

|---|---|---|---|---|---|---|

| AZ91D magnesium alloy | 230 MPa | 3.0 % | 150 MPa | 1.81 g/㎤ | 595 °C | 44.8 GPa |

| AZ80A magnesium alloy | 290 MPa | 2~5.0 % | 179 MPa | 1.81 g/㎤ | 595 °C | 45 GPa |

| AZ31B magnesium alloy | 280 MPa | 8 % | 160 MPa | 1.76 g/㎤ | 596 °C | 46 GPa |

| ZK61B magnesium alloy | 330 MPa | 12 % | 178 MPa | 1.81 g/㎤ | 630 °C | 47GPa |

| AZ61B magnesium alloy | 280 MPa | 14 % | 165 MPa | 1.81 g/㎤ | 653 °C | 45 GPa |

| AM60B magnesium alloy | 221 MPa | 4.0 % | 131 MPa | 1.81 g/㎤ | 482 °C | 44.8 GPa |

Magnesium Machining Capabilities Include

We are equipped with advanced 3-axis, 4-axis and 5-axis CNC machining centers, including Haas, Jingdiao and other high-speed CNC milling machines. We can handle a variety of magnesium alloy material, aluminum alloy material milling projects requiring high precision and complex shape machined parts, and provide extremely tight tolerances and excellent surface finish.

1.Magnesium CNC Milling Capabilities

| Machining Type | Minimum Wall Thickness | Minimum End Mill Size | Minimum Drill Size | Maximum Part Size |

|---|---|---|---|---|

| 3 Axis CNC Machining | 1mm | 1mm x 2mm x 2mm | 0.5mm | 1100mm x 800mm x 650mm [x,y,z] |

| 4 Axis CNC Machining | 1mm | 1mm x 2mm x 2mm | 0.5mm | 550mm x 350mm x 200mm [x,y,z] |

| 5 Axis CNC Machining | 1mm | 1mm x 2mm x 2mm | 0.5mm | 550mm x 350mm x 200mm [x,y,z] |

Radius : Depth – Machining tolerance is +/- 0.01mm. It is recommended that all areas of the part be thicker than 0.51mm

2.Magnesium CNC Turning Capabilities

| Machining Type | Biggest Size | Minimum Size Diameter | Length | Wall Thickness | Angle |

|---|---|---|---|---|---|

| Cnc Turning | 260*1100mm | 0.1mm | 0.2mm | 0.25mm | 30° |

3.Magnesium Die Casting Capabilities

| Machining Type | Smooth | Semi-Gloss | Matte | Textured |

|---|---|---|---|---|

| Magnesium Die Casting | Class A finishes are produced using a diamond polishing process that produces a shiny surface on injection molded parts. | A Class B finish uses coarse sandpaper to produce a rougher part than a Class A part. Custom-molded plastic parts with a Class B finish have a matte surface texture. | Class C finishes use coarse grit to create a rough, uneven surface. Injection molded parts with a C finish have a matt surface texture. | Class D finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, the product can have a satin or matte finish. |

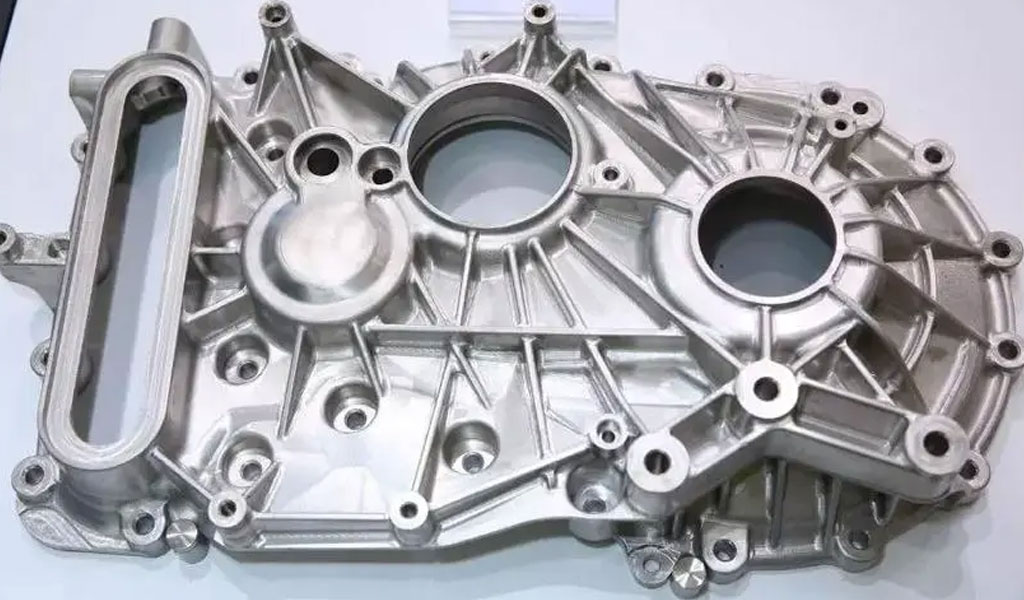

Top China Magnesium Cnc Machining Parts & Case Studies

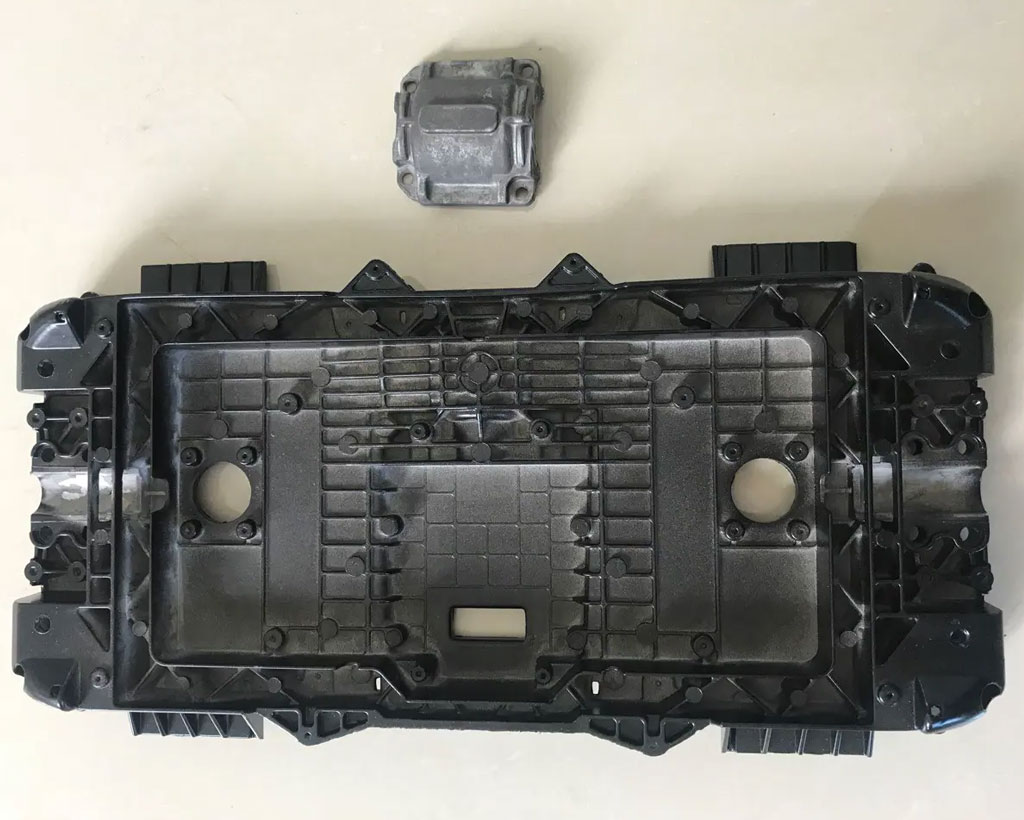

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make magnesium prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making magnesium concept models and precise functional components. Understanding the properties of different magnesium alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on magnesium alloy. Be-cu prototyping company provides a range of solutions for the machining of magnesium parts.

-

Extrusion Die-casting Magnesium Alloy Heat Sink Shell

-

Manufacturers Open Mold Casting Magnesium Alloy Shell

-

AZ61A Magnesium Alloy Die Casting Machinery Parts

-

AZ61M Magnesium Alloy Die Casting Machinery Parts

-

Custom Magnesium Alloy Car Steering Wheel By Die Casting

-

Magnesium Die Casting Mechanical Equipment Parts

Common Industries Served In Be-Cu.com

We work closely with a wide variety of industry-leading OEMs, manufacturing complex Magnesium Cnc Machining components that meet stringent application requirements for demanding and challenging environments.While we work with and serve all industries, our work focuses on the following industries:

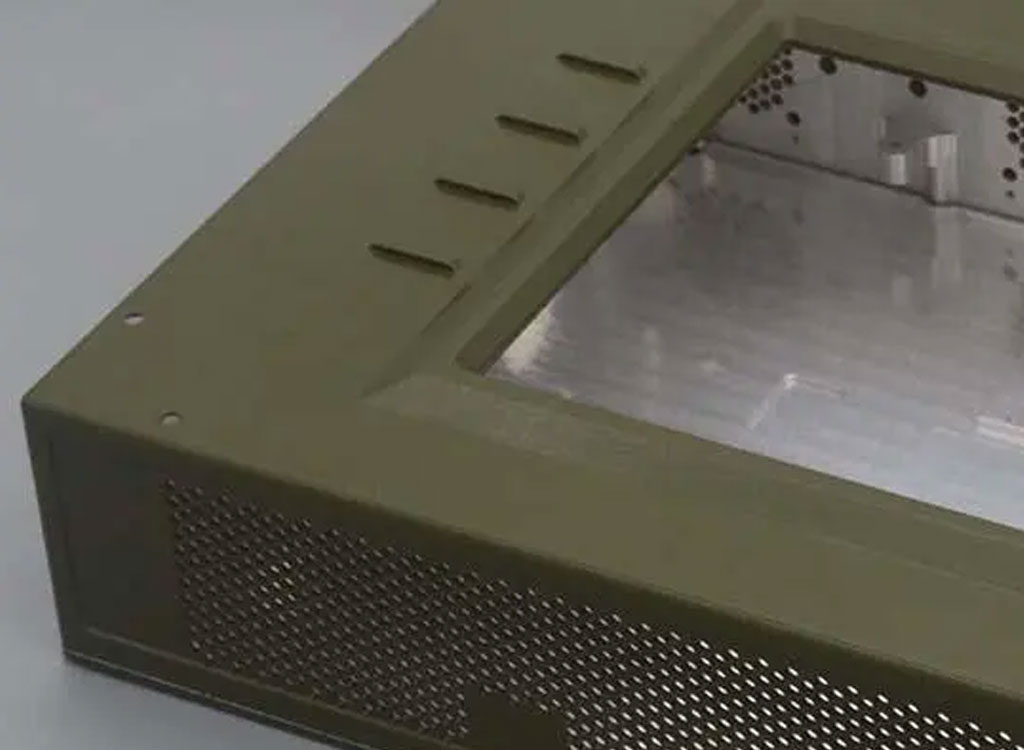

Reinforced Electronic Parts And Enclosure

The reinforced electronic enclosure has the characteristics of waterproof, dustproof, rainproof, salt spray proof, shock and vibration resistance, high and low temperature resistance, and excellent electromagnetic compatibility.

It meets the requirements of GJB151A, GJB150, GJB322A and other relevant standards, and is suitable for harsh and harsh environments in the field.

According to the needs of customers, we carry out reinforced electronic enclosure structure design, appearance design, power supply design, electromagnetic compatibility analysis, heat distribution calculation and heat dissipation design to meet the requirements of national standards.At the same time a more responsive supply chain to better respond to the demand for more custom magnesium alloy products for reinforced products.

BE-CU has long-term cooperation with special institutes and enterprises such as aerospace, science and technology, China Special, Electronic Technology, and China Shipbuilding. Our main business is to provide customers with reliable electronic chassis and highly reliable liquid cooling solutions, with the aim of improving the reliability and stability of electronic equipment working in extreme environments.

Aerospace Industries

Customized CNC Machining ATR aviation chassis, 19-inch 1U~6U aviation chassis, portable CPCI, PXI, PXIe, VPX aviation chassis

It meets the requirements of the national standard and is suitable for platforms such as airborne, shipborne, vehicle-mounted, missile-borne, and ground stations. The product has high mechanical structure strength and strong vibration and shock resistance.The chassis can adopt conduction heat dissipation and forced air cooling to ensure that the equipment can work normally within the specified ambient temperature range.

Excellent electromagnetic compatibility and anti-interference protection ability, meeting the relevant requirements of GJB 151B-2013.

Communication And Telecom Chassis

The company’s main cnc machining and manufacturing products include handheld remote controllers, vehicle-mounted transmitters; communication control system receivers, communication control system vehicle-mounted transmitters, robot intelligent communication vehicle-mounted terminals, and MESH communication series product shells/boxes based on special intelligent communications .

The electronic communication housing/cabinet is made of magnesium alloy material through CNC machine, and can pass environmental tests such as salt spray, mold and damp heat.It has anti-vibration, electromagnetic shielding, environmental protection and other performances, and at the same time meets the requirements of special environments to make the equipment work normally. It is small in size, light in weight, easy to operate and easy to carry.

Liquid Cooling System Equipment

Be-Cu pprototype main magnesium cnc machining and manufacturing products include liquid cold plates, vapor chambers, cold pipe vapor chambers, chassis liquid cooling systems, and product shells and boxes for liquid cooling systems.Through CAE performance analysis, complete the heat dissipation analysis of the natural conduction, fluid, and composite methods of the special machine chassis and components

Meet the installation and heat dissipation requirements of electronic components such as IGBT, CPU, GPU, SVG resistors, and power amplifiers.Excellent heat dissipation performance, good temperature uniformity performance, low flow resistance, high mechanical strength and corrosion resistance.

Online Cooperate With Magnesium Alloy Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered magnesium alloy components on the planet. We have both precision 5 axis machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.