Advance Magnesium Die Casting Supplier In China

In Die Casting Process,Magnesium alloy Corrosion and mechanical properties have many characteristics: fast heat dissipation, light weight, good rigidity, certain corrosion resistance and dimensional stability, impact resistance, wear resistance, good attenuation performance and easy recycling; in addition, It has the characteristics of high thermal and electrical conductivity, non-magnetic, good shielding and non-toxic.

The Advantage Of Magnesium Die Casting

- Although the specific gravity of magnesium alloy is heavier than plastic, its strength and elastic modulus per unit weight are higher than that of plastic. Therefore, with the same strength parts, magnesium alloy parts can be made thinner and lighter than plastic. In addition, since the specific strength of magnesium alloy is higher than that of aluminum alloy and iron, the weight of aluminum or iron parts can be reduced without reducing the strength of the parts.

- Magnesium alloy has the highest relative strength (ratio of strength to mass). The specific stiffness (ratio of stiffness to mass) is close to aluminum alloy and steel, much higher than engineering plastics.

- In the elastic range, when magnesium alloy is subjected to impact load, the energy absorbed is half larger than that of aluminum alloy parts, so magnesium alloy has good shock resistance and noise reduction performance.

- The melting point of magnesium alloy is lower than that of aluminum alloy, and its die-casting performance is good. The tensile strength of magnesium alloy castings is equivalent to that of aluminum alloy castings, generally up to 250 MPa, up to more than 600 MPa. Yield strength and elongation are not much different from aluminum alloys.

- Magnesium alloy also has good corrosion resistance, electromagnetic shielding performance, and radiation protection performance, which can be 100% recycled and reused.

- Magnesium alloy parts have higher stability. The casting line of die casting parts has high dimensional accuracy and can be processed with high precision.

- Magnesium alloy has good die-casting forming performance, and the minimum wall thickness of die-casting parts can reach 0.5mm. It is suitable for manufacturing all kinds of die-casting parts of automobiles.

- However, the coefficient of linear expansion of magnesium alloy is very large, reaching 25~26 μm/m℃, while that of aluminum alloy is 23 μm/m℃, brass is about 20 μm/m℃, structural steel is 12 μm/m℃, and cast iron is about 10 μm/m. m℃, rock (granite, marble, etc.) is only 5-9 μm/m℃, and glass is 5-11 μm/m℃.

Looking for precision magnesium alloy parts customized by an experienced and reliable die casting components manufacturer? Be-cu’s custom die casting services can be your ideal choice. We are very experienced in magnesium casting including magnesium die casting. With strong capability of casting a wide variety of magnesium steel alloys such as AZ91D, AM60B and AM50, we provide custom magnesium casting parts and components for industries and applications including automotive, food & dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others. We can assure you high quality magnesium castings. All of our magnesium alloy die casting components are subject to our rigorous inspection regime with designated inspectors, in-process inspection and a full final inspection completed on every part.

- AZ91D: Most commonly used alloy for high pressure die casting. Offers good strength to weight ratio, very good corrosion resistance and excellent castability. This alloy is typically used for power-train and mechanical components where toughness is more important than deformation capability.AZ91D isn’t limited to only magnesium die casting and is used frequently in other field such as cnc machining magnesium alloy.

- AM60B: Commonly used for automotive die castings for safety components such as instrument panel structures and seat frames. This alloy offers excellent ductility, energy absorbing properties, strength and castability.

- AM50: With a lower aluminum content than AM60 this alloy offers a further increase in ductility but at a slightly reduced strength and a slight reduction in castability. It is typically used where the performance requirements demand elongation properties beyond that of AM60.

BE-CU.com have a wide range of metal materials that can be selected according to your needs, more additional material requests please contact us.

Why Choose BE-CU Magnesium Die Casting Service?

- Modern and advanced casting equipment to ensure highest accuracy of Magnesium die casting parts.

- Vacuum die casting machine in house

- Magnesium alloy die casting can produce 0.2mm products

- 50 set cnc machine for machined castings parts,metal, extrusion etc.

- Powder coating production line,CMM,X-ray in house

- Design and produce complex custom zinc parts

- Has strong and professional technical team and efficient management operation system and is equipped with advanced manufacturing equipment, ensure you can get best zinc parts of die casting service.

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Magnesium Die Casting Material Information

| Mechanical Properties | AZ91D | AM60B | AM50A |

|---|---|---|---|

| Ultimate Tensile Strength (Mpa) | 240 | 225 | 210 |

| Yield Strength (Mpa) | 160 | 130 | 125 |

| Elongation (% ub 2 in (51mm) | 3 | 8 | 10 |

| Hardness (Brinell) | 75 | 70 | 65 |

| Elastic Modulus (Gpa) | 45 | 45 | 45 |

| Physical Properties | AZ91D | AM60B | AM50A |

|---|---|---|---|

| Density (g / cm³) | 1.81 | 1.80 | 1.77 |

| Melting Range (F) | 815 to 1,108 | 815 to 1,139 | 815 to 1,238 |

| Melting Range (C) | 435 to 598 | 435 to 615 | 435 to 620 |

| Specific Heat (kJ/kg k) | 1.02 | 1.02 | 1.02 |

| Thermal Conductivity (W / m – k ) | 51 | 61 | 65 |

| Electrical Conductivity (MS/m) | 6.6 | 9.1 | – |

| Corrosion Rate (mg/cm²/day) | 0.05 | 0.09 | 0.1 |

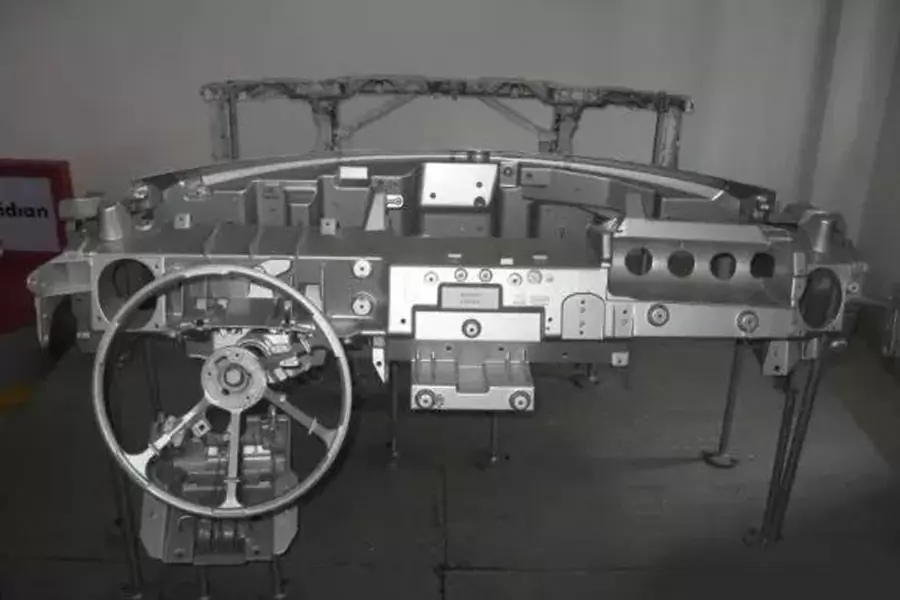

Product Description Of Our Magnesium Die Casting Services

Magnesium Die Casting Applications:

Magnesium die casting parts can be applied to jewelry, Automobile, electronic, wireless charging, dash cam, recorder, Bluetooth speaker, smart watch, smart home

Custom Colors:

Black, Natural, Blue, Green and different colors as your requirements

Surface Finishing:

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Various Magnesium Die Casting Process:

Magnesium Thin Wall Die Casting,Magnesium Cold Chamber Die Casting, Magnesium Hot Chamber Die Casting

Top Magnesium Die Casting Case Studies

You have a complex part design, Be-cu Die Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Extrusion Die-casting Magnesium Alloy Heat Sink Shell

-

Manufacturers Open Mold Casting Magnesium Alloy Shell

-

AZ61A Magnesium Alloy Die Casting Machinery Parts

-

AZ61M Magnesium Alloy Die Casting Machinery Parts

-

Custom Magnesium Alloy Car Steering Wheel By Die Casting

-

Magnesium Die Casting Mechanical Equipment Parts