PolyJet 3D Printing

- Single Print Dimensions: Maximum print size of 49 x 39 x 20 cm (19.3 x 15.35 x 7.9 inches); Minimum size of 2.5 x 2.5 x 2.5 cm.

- Layer Resolution: X-axis: 42μm, Y-axis: 42μm, Z-axis: 16μm.

- Achievable Precision: Dimensional accuracy of ±0.1mm (for lengths ≤ 100mm) or ±0.1% × L (for lengths > 100mm).

- Post-processing Options: Capable of polishing, painting, electroplating, and drilling, with the ability to join larger parts.

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Polyjet 3D Printing Service – China Top Polyjet Printing Service & Parts Supplier

BE-CU offering Polyjet 3D Printing Service services for the art,prototype, automotive, performance racing, vehicle, medical, healthcare, architecture,consumer goods and aerospace industries. Custom manufacturing network providing PolyJet 3D printing technology services for ABS, PET-G and PLA materials. Capable of manufacturing parts with 0.2 to 0.25 mm resolution and +/-0.5 mm tolerance.Prototype volume production is available. Instant quotes available within seconds. Turnaround time is 2 days. Anonymized drawings available.

The revolutionary capability of our polyjet 3d printing service to support full-color and multi-material printing combines the functionality and realism of true-color PolyJet 3D printing technology with the diversity of materials and processes, offering high-precision colored prototypes, parts, and assemblies. Unlike conventional 3D printing, which often necessitates post-processing to achieve the desired features, this technology allows for seamless integration of multiple materials and colors in a single print job.

We can produce objects in five different base colors: Cyan, Magenta, Yellow, Black, and White. Utilizing CMYK color processing, it can print a wide range of colors (including solid colors) and create color 2D files or 3D objects with rich backgrounds, details, and patterns. The wide color gamut ensures that the printed objects have vivid and precise color reproduction, even when printing subtle gradients or transparent effects.Fast prototyping with exceptional fidelity to design and realistic texture gives designers ample creative freedom. The ability to produce multiple iterations of a design in a single batch allows for rapid visualization and refinement, leading to more efficient, cost-effective, and superior design processes.

PolyJet 3D Printing Design Guidelines

PolyJet 3D printing technology is an advanced full-color manufacturing technology that uses the accumulation of layers of photocurable resin to create three-dimensional objects.

- Ensure the model is a solid object, not a hollow one; wall thickness must be at least 1mm.

- The minimum and maximum detail resolutions for various features:Raised or embossed text: Minimum height and width: 1mm; Minimum stroke width: 1mm.Engraved text: Minimum depth: 0.5mm; Minimum gap between letters: 0.4mm; Printing accuracy ±0.1mm.

- When exporting files in VRML (.wrl), OBJ, or PLY formats, the minimum size for color models is crucial. If using OBJ files, ensure all accompanying texture files are correctly mapped and exported in PNG format.

- To prevent model damage, designers should consider adding structural support. If the model has delicate features, it should be cleaned with care to avoid breakage.

Advantage Of PolyJet 3D Printing Service

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

Polyjet Materials – The Material Of Polyjet 3D Printing Service

The Objet VeroGray FullCure850, VeroBlack FullCure870, and VeroWhitePlus FullCure835 are photo-curable resin materials that are similar to ABS, featuring an opaque white or colored appearance and durability.

| Technical Performance | Trial Method | Metric |

|---|---|---|

| Tensile Strength | ASTM D638-03 | 56-65 MPa |

| Elongation at Break | ASTM D638-05 | 10-25% |

| Elastic Modulus | ASTM D638-04 | 2,000-3,000 MPa |

| Bending Strength | ASTM D790-03 | 75-110 MPa |

| Flexural Modulus | ASTM D790-04 | 2,200-3,200 MPa |

| Lzod Notched Impact | ASTM D256-06 | 20-30J/cm |

| Shore Hardness (D) Scale | ASTM Scale D | 83-86 |

| Rockwell Hardness Scale M scale | ASTM Scale M | 73-76 |

| Ash Content | ASTM USP281 | 0.23-0.26% |

| Water Absorption | ASTM D570-98 24hr | 1.1-1.5% |

| Heat Deformation HDT @ 0.45MPa | ASTM D648-06 | 40-50°C |

| Heat Deformation HDT@ 1.82 MPa | ASTM D648-07 | 40-50°C |

| Glass Transition Temperature Tg | ASTM DMA, E» | 52-54°C |

PolyJet 3D Printing Applications – What is PolyJet 3D Printing Used for

Compared with traditional processing and manufacturing technologies, PolyJet 3D printing technology has the advantages of fast molding speed, high precision, and manufacturing complex structures. It is widely used in the fields of automobiles, medical equipment, industrial manufacturing, etc.China Top PolyJet 3D Printing Supplier & Manufacturer – Be-cu offers worldwide clients affordable, rapid, high precision custom PolyJet 3D Printing Services, variety of materials available to meet the needs of different industries!

What Is PolyJet 3D Printing?

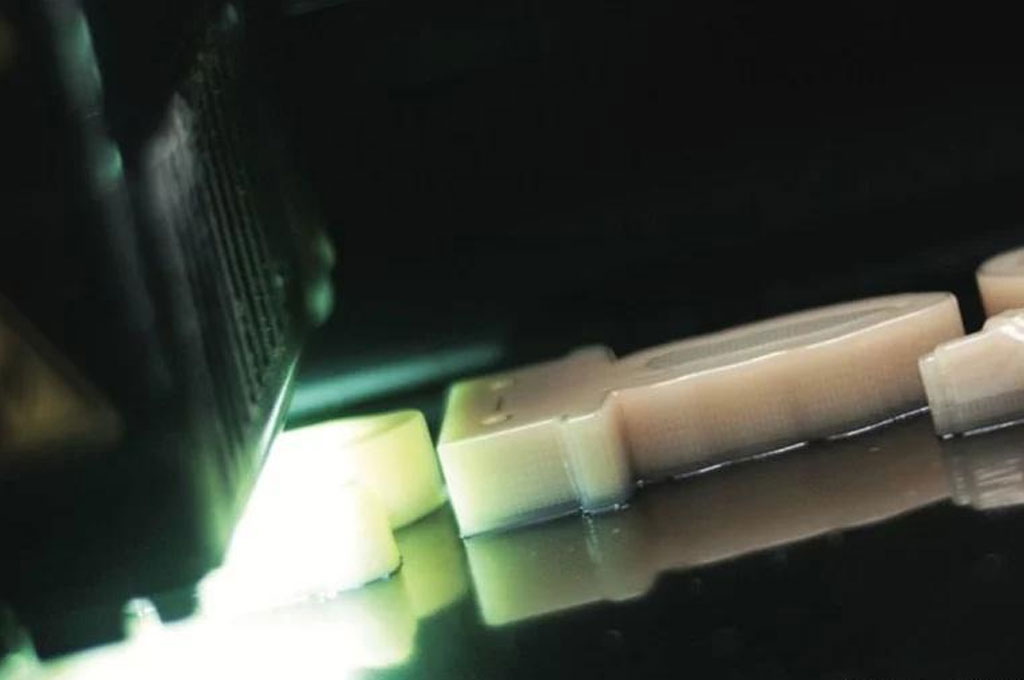

PolyJet can be considered a close relative of fused deposition technology. Like FDM printing, it works by printing parts layer by layer using an extrusion head. However, instead of depositing material as filaments on the print bed, PolyJet operates in a manner more akin to 2D inkjet printing, depositing tiny droplets of the chosen photopolymer material onto the print bed, which are then cured with ultraviolet light.

PolyJet 3D printing offers naturally smooth surface quality, which significantly reduces the need for additional sanding or polishing during post-processing. On the other hand, polymer parts can be dyed and painted like SLS parts, offering many options for creating unique finishes. PolyJet parts can also be bonded if necessary, allowing for the printing of larger parts as separate components that can be assembled together.

How Does PolyJet 3D Printing Work? – Steps of PolyJet 3D Printing Process

PolyJet 3D printing involves spraying liquid photopolymer layers onto a build tray and immediately curing them with ultraviolet light. Thin layers are gradually accumulated to form the model until a complete 3D model is created. Models produced by PolyJet printers can be used and handled directly without further curing. The molding principle of PolyJet technology is somewhat similar to 3DP, but instead of using an adhesive, it uses resin materials.

While not as widely used as SLS or SLA, it holds a significant position in the niche of 3D printing processes and is an effective production tool for creating smooth-surfaced, dimensionally precise parts, prototypes, and tools.This technology offers microscopic layer resolution and accuracy down to 0.1 mm. It can create thin-walled and complex geometries using a variety of materials suitable for any technology. Its applications include:

- Printing fine prototypes with smooth surfaces, showcasing the aesthetic quality of the final product.

- Manufacturing precise molds, drill jigs, fixtures, and other manufacturing tools.

- Handling complex shapes and details, presenting intricate features.

- Combining multiple colors and material types in a single model, enhancing efficiency.

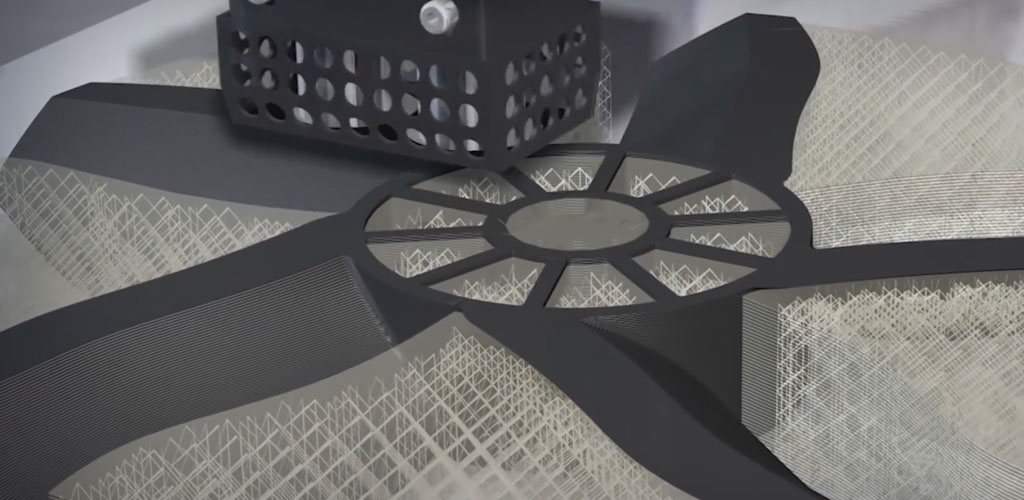

The Case Studies Of Multi Color PolyJet 3D Printing Parts

The ability to create parts with multiple colors and materials in a single monolithic print means that PolyJet material jetting technology is suitable for a wide range of applications across various industries, creating accurate, visually stunning models from prototyping to low-volume production without the need for tooling. You have a complex part design, Our PolyJet 3D printing service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.