What Is Oil And Gas CNC Machining

The oil and gas industry has long been a cornerstone of the global economy, providing the energy resources that power our world. However, the extraction, processing, and transportation of these valuable resources come with numerous challenges, including the need for precision engineering and manufacturing.

The oil and gas industry requires a wide range of complex components, such as valves, pumps, connectors, flanges, drilling tools, and downhole equipment. These components must be manufactured with precision to meet stringent industry standards and safety regulations.Some oil and gas components, such as pipeline fittings or wellhead equipment, are produced in large quantities to meet the demands of the industry.

Oil and gas machining often involves working with materials that can withstand extreme conditions, including high pressure, high temperatures, and corrosive environments.Common materials include various grades of steel, stainless steel, and specialized alloys designed for oil and gas applications.

CNC machining is a manufacturing process that utilizes computer-controlled machines to produce precise and complex parts and components. It has revolutionized various industries, due to its unparalleled accuracy and repeatability,In the oil and gas sector, where reliability and precision are paramount, CNC machining has become indispensable.From the exploration of oil and gas reserves to the refinement and distribution of the final products, CNC machining plays a critical role in ensuring efficiency, safety, and reliability.

Oil And Gas Machining Shops – CNC Oil And Gas Machining

As a dedicated professional cnc machining shop with a passion for precision engineering and a firm belief in the transformative power of machining technology,Be-Cu prototype am excited to contribute to the advancements and innovations in the oil and gas industry.From the intricate components used in drilling operations to the critical elements of safety systems in oil refineries, precision machining plays an indispensable role in the oil and gas industry.

Every piece produced must meet the highest standards of quality, durability, and reliability to ensure the smooth and safe extraction, processing, and transportation of vital energy resources.

Over 30 years, Be-Cu have honed skills in precision machining, mastering various machining processes such as turning, milling, and drilling.Be-Cu frequently help aid our customers design custom components which consistently meet these strict requirements and regulations.Be-Cu understands how each component fits into the project as a whole and its application of use, allowing our machinists to effectively machine parts so they fit perfectly into their assembly.

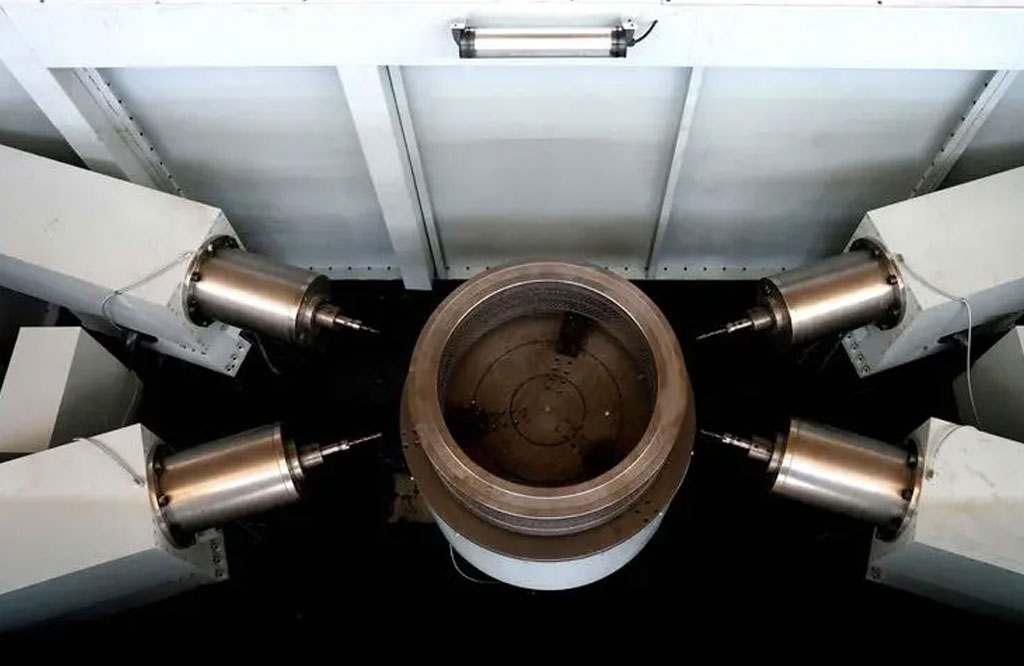

Our state-of-the-art multi-axis CNC machining and milling equipment enable us to deliver machined oil and gas components that meet your rigorous demands and match your design tolerances with accuracy of ±0.0005” or better.Be-Cu machinists welcome any challenge and have machined complex components with the highest precision and accuracy possible, exceeding the standards set and made what appeared impossible possible.

CNC Machining Components We Build for the Oil & Gas Industry

High precision custom solutions actually do exist for a variety of problems you face. What Be-Cu does so well is to create custom ultra-precision components other machine shops are unable to match.

Valve Bodies and Components

Pump Parts

Connectors and Flanges

Manifolds

Downhole Tools

Instrumentation and Sensors

Subsea Equipment Parts

Mud Motor Components

Hydraulic Components

Rotary Table Components

Heat Exchanger

Threaded Connections

Custom Tooling and Fixtures

Control Panels and Enclosures

Safety Components

Our skilled CNC machinists work closely with you to custom-engineer the highest quality components which fit your specific project needs. For top quality, tight tolerance Oil & Gas CNC machining with unrivaled customer service, look no further than Be-Cu prototype.

Why Choose Our Oil & Gas Machining Service?

- Save time and money for your Oil & Gas project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex Oil & Gas machined parts & components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Oil & Gas Cnc Machining Parts & Case Studies

With the continuous maturity and development of CNC Machining technology, more and more Oil & Gas manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the Oil & Gas industry, the application of CNC Machining in Oil And Gas industry, how CNC Machining changes the Oil And Gas manufacturing supply chain, and more.Some examples of o ptical products we can manufacture are:

-

Brass Direct Injection Flame Distributor Nozzle For Gas Stove

-

CNC Machining Brass Natural Gas Kitchen Appliance Valve Core

-

Carbide Tungsten Valve Seat For Oil And Gas Industry

-

CNC Milling Off-White Flame-Retardant ABS Plastic Parts

-

Precision Machining High-Impact ABS Parts

-

5 Axis Turn-Mill Machining Brass Parts

-

Big Size CNC Machining Lost Foam Casting Parts

-

Swiss CNC Machining And Turning Brass 360 Shaft

-

Milling Machining Wear-Resistant Precision Brass Spare Parts

-

CNC Milling Brass Oil-free Rail Slideway Slider

-

Brass Grip Fitting Cover DN-59

-

Turn-Mill Machining Precision Brass Parts

-

Black POM CNC Machining Non-Standard Machinery Parts

-

Precision CNC Turning N9 Copper Parts

-

Swiss Turning Gold-Plated T2 Copper Parts

-

CNC Machined Rotary Head Aluminum Parts