SLA 3D Printing

- MAX PART SIZE:145 × 145 × 175 mm (5.7″ x 5.7″ x 6.8″)

- LEAD TIMES:From 5 Working Days

- TOLERANCE:± 0.5% with a lower limit of ± 0.15 mm (± 0.006″)

- MIN PART SIZE:1 x 1 x 8 mm

- LAYER HEIGHT:100 microns

- MIN WALL THICKNESS:1.0 mm

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

SLA 3D Printing Service – China Leading Stereolithography Parts Supplier

SLA is an additive manufacturing process that uses UV laser to cure liquid resin into hardened plastic. This 3d printing technology allows us to 3d print parts with precision and accuracy.Looking for low cost SLA 3D Printing parts with unparalleled quality? Be-cu is a professional China 3D Printing manufacturer provides superior stereolithography services with advanced machines including UnionTech LITE 4100 HD SLA 3D printer and G2100 SLA 3D printer from the general industrial grade printer and accomplished machinists.

From prototyping to small-batch production, our global network of certified SLA 3D printing facilities will allow you to produce highly accurate parts with quality and strength comparable to injection molding.Upload your CAD files, receive an instant Selective Laser Sintering 3D printing quote and get your parts into production in less than 5 minutes.

Our expertise in additive manufacturing, high-end functional testing prototypes, 24 hours services, competitive price, on time delivery drop- shipping to over 150 countries to help you transform your ideas into projects, bring your innovative products to market faster, reduce your production costs, save your research and development time.Metal finishing service is a essential choice to achieve your design perfectly. Be-cu is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide SLA 3D Printing services and a wide range of surface treatment services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. Here are the introductions to different types of metal finishes, more details please feel free to contact us.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

Why Choose Be-cu SLA 3D Printing Service

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

The Material Of SLA 3D Printing

At a time when general-purpose resin materials began to develop, and while manufacturers of 3D printing resin equipment sold their proprietary materials, a large number of resin manufacturers, including MadeSolid, MakerJuice, and Spot-A, emerged in response to market demand. Initially, tabletop resins were limited in color and performance, when only yellow and clear materials were possible. In recent years, colors have expanded to include orange, green, red, yellow, blue, white, and more.

Hard Resins

Casting Resin

Flexible Resins

Elastic Resin

High Temperature Resin

Biocompatible Resins

Ceramic Resin

If you are having any problem to get your SLA 3D printing parts done, contact us and try to get a solution from BE-CU.

SLA 3D Printing Applications – What is SLA 3D Printing Used for

China Top SLA 3D Printing Supplier & Manufacturer – Be-cu offers worldwide clients affordable, rapid, high precision custom SLA 3D Printing Services, variety of materials available to meet the needs of different industries!

What Is SLA 3D Printing? – SLA 3D Printing Define

SLA printing technology, the full name of Stereo lithography Appearance (Stereo lithography Appearance), uses a laser to focus on the surface of the light-cured material, so that it solidifies sequentially from point to line, from line to surface, and repeats itself, so that the layers are superimposed to form a three-dimensional entity.The principle of SLA 3DP (light curing) is the activation energy generated by ultraviolet light with the highest energy in the spectrum, which can break the C-C bond of the unsaturated polyester resin and generate free radicals to cure the resin.When a photosensitizer is added to the unsaturated polyester resin, it is initiated by ultraviolet or visible light as an energy source, which can make the resin cross-linking reaction quickly.

Therefore, the material of the SLA process is photosensitive resin, which needs to be filled with the entire material tank. The main working equipment is a laser and a galvanometer. The galvanometer irradiates the ultraviolet light emitted by the laser onto the liquid surface of the specified material tank through computer-controlled polarization to cure it. , the model is divided into N slices by the computer in advance, and each slice can be regarded as a two-dimensional plane. After curing a slice plane, the stencil will bring the model down to the next slice plane, and so on until the printing is completed.

How Does SLA 3D Printing Work? – Steps of SLA 3D Printing Process

- First, place the build platform in the liquid photopolymer tank, one layer above the liquid surface.

- Second, the UV laser then creates the next layer by selectively curing and curing the photopolymer resin. The laser beam is focused on a predetermined path using a set of mirrors called galvo mirrors. The entire cross-section of the model is scanned, so the resulting part is completely solid.

- After coating a layer, the platform moves a safe distance and cleans the blade to re-coat the surface. The process is then repeated until the part is complete.

- After printing, the parts are in an incompletely cured green state, if high mechanical and thermal properties are required, further post-processing under UV light is required.

The Advantage Of SLA 3D Printing

Compared with other 3D printing processes, SLA 3D printing has the characteristics of a wide range of printing shapes, fast forming speed, high precision and the best surface finish. The application field includes almost all industries in the manufacturing field, in medical, ergonomic, cultural relics protection and other industries. It has also been more and more widely used.

At present, it is mainly used in the design verification of new product development and the trial production of simulated samples, that is, the development process from product conceptual design → modeling design → structural design → basic function evaluation → simulated sample trial production is completed. For some products mainly made of plastic structure, small batch trial production can also be carried out, or some physical functional tests, assembly verification, actual appearance effect review, and even small batch assembly of products can be put on the market first, so as to achieve the purpose of asking for directions.

Liquid resins are cured through a process called photopolymerization: During curing, the monomeric carbon chains that make up the liquid resin are activated by light from a UV laser and become solid, forming strong, unbreakable bonds with each other. The photopolymerization process is irreversible and cannot convert SLA parts back to a liquid state: when heated, they burn rather than melt. This is because materials produced with SLA are made of thermoset polymers, as opposed to thermoplastics used in FDM.

In an SLA system, most printing parameters are determined by the manufacturer and cannot be changed. The only inputs are the layer height and the part orientation (the latter determines the support location).

Typical layer heights in SLA are between 25 and 100 microns. Lower layer heights capture curved geometries more accurately, but increase build time (and cost) and the likelihood of print failure. A layer height of 100 microns is suitable for most common applications.

The floor area is another parameter that is important to the designer. Build size depends on the type of SLA machine.

The Supporting Structure Of SLA 3D Printing

Support structures are always required in SLAs. The support structure is printed using the same material as the part and must be removed manually after printing. The orientation of the part determines the location and number of supports. It is recommended to orient the part so that visually critical surfaces do not come into contact with the support structure.Bottom-up and top-down SLA printers use support differently:

In top-down SLA printers, support requirements are similar to FDM. They are needed to accurately print overhangs and bridges (critical overhang angles are typically 30o). Parts can be oriented in any position, and they are usually printed in a flat shape to minimize the amount of support and the total number of layers.

In bottom-up SLA printers, the situation is more complicated. Overhangs and bridges still need to be supported, but minimizing the cross-sectional area of each layer is the most critical criterion: the forces applied to the part during the peeling step can cause the part to detach from the build platform. These forces are proportional to the cross-sectional area of each layer. Therefore, the parts are oriented at an angle and the reduction of supports is not a major issue

In an SLA system, most printing parameters are determined by the manufacturer and cannot be changed. The only inputs are the layer height and the part orientation (the latter determines the support location).Typical layer heights in SLA are between 25 and 100 microns. Lower layer heights capture curved geometries more accurately, but increase build time (and cost) and the likelihood of print failure. A layer height of 100 microns is suitable for most common applications.The floor area is another parameter that is important to the designer. Build size depends on the type of SLA machine.

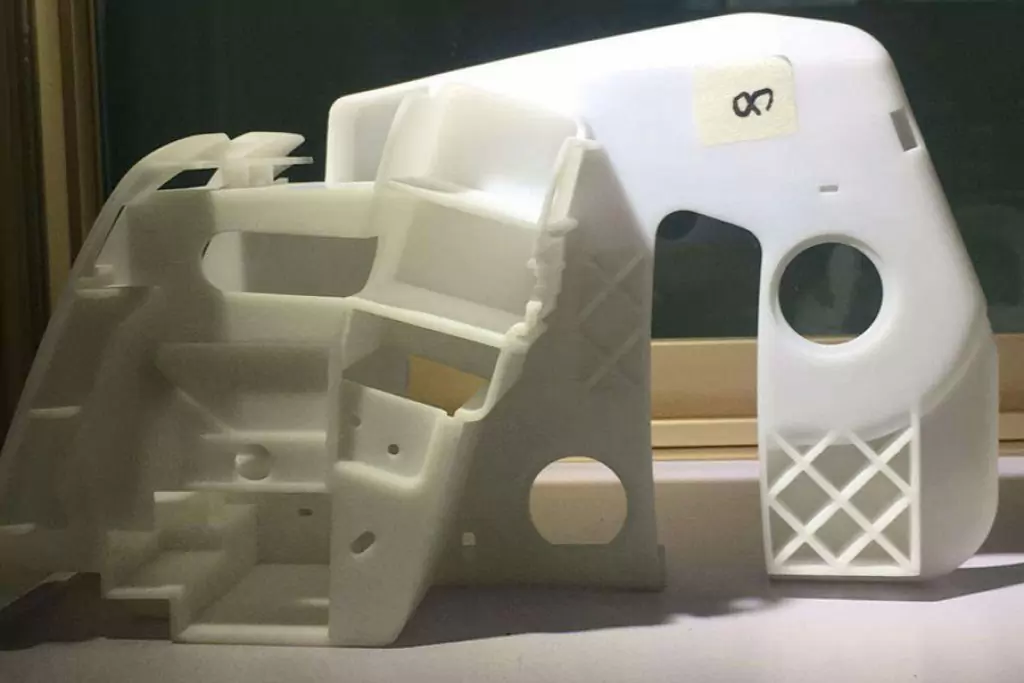

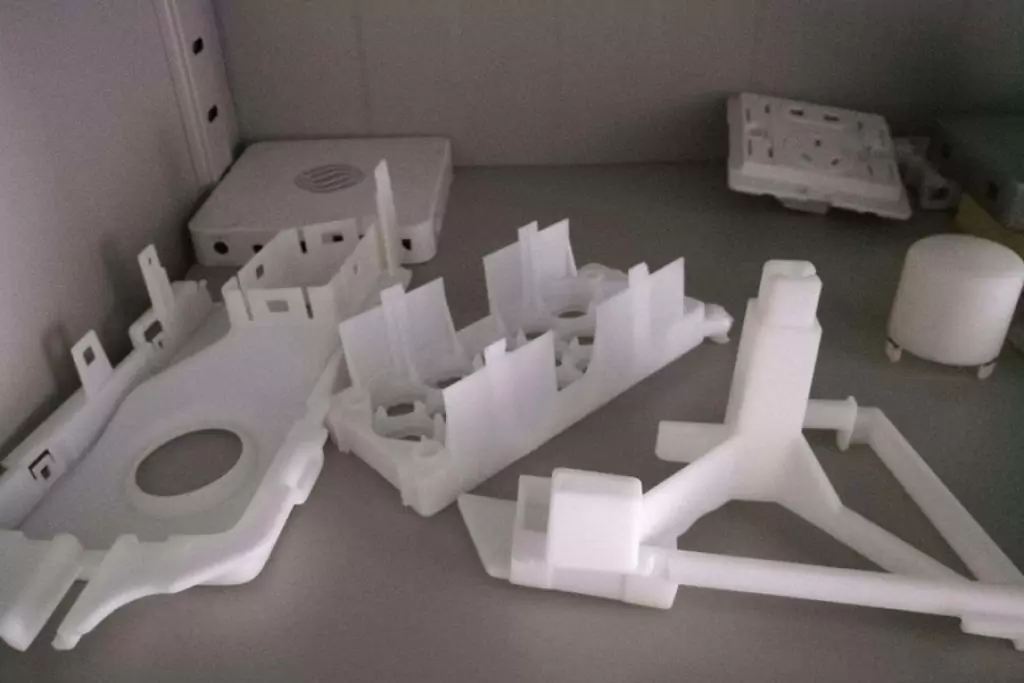

The Case Studies Of SLA 3D Printing Parts

You have a complex part design, Our SLA 3D printing service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Development Resin Samples For Sports Shoes

-

3D Printed Sports Shoes Sole Model

-

Powder Sintering 3D Printed Shoe Midsole Sample

-

3D Printing Brown Wax Anime Doll

-

100% Reproduction 3D Printed Penguin Family Model

-

SLA 3D Printed Liu Bang Character Model

-

Colorful 3D Printed Winnie The Pooh Model

-

3D Printed Bike Fender

-

Rapid Prototyping and 3D Printed Bike Light

-

3D Scan And SLA Printing Money Tree Ornaments