Shoe Midsole Sample

Product name: Shoe Midsole Sample

No+Color:Custom

Surface treatment:Custom

Product material: 3D Printting Material

Proofing cycle:7 days(100000 pcs/M)

Machining Factory:BE-CU.com

Production Process: 3D Printing Shoes

Size:According To Customer Drawings

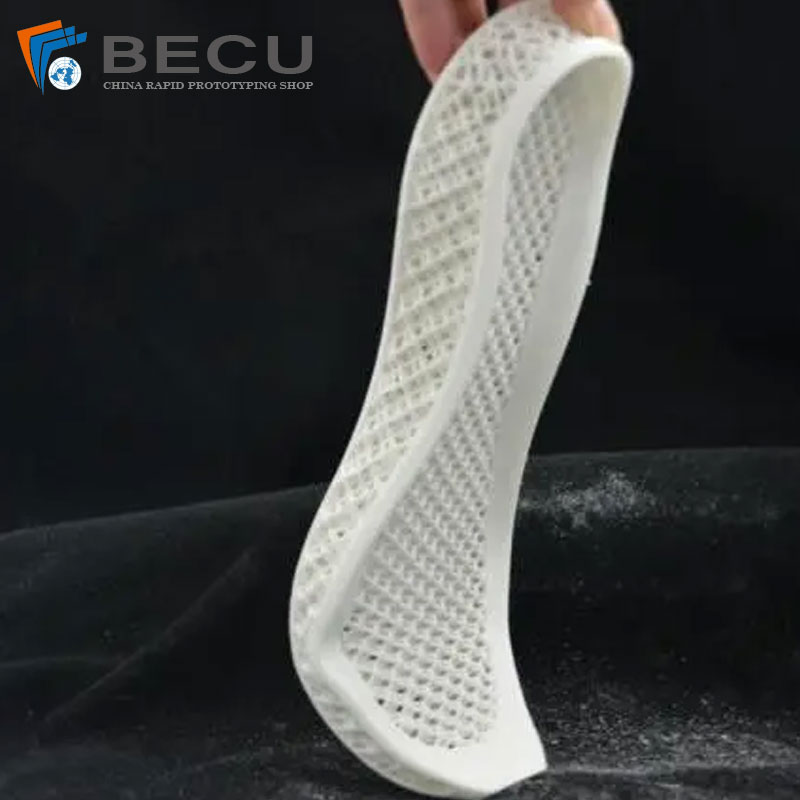

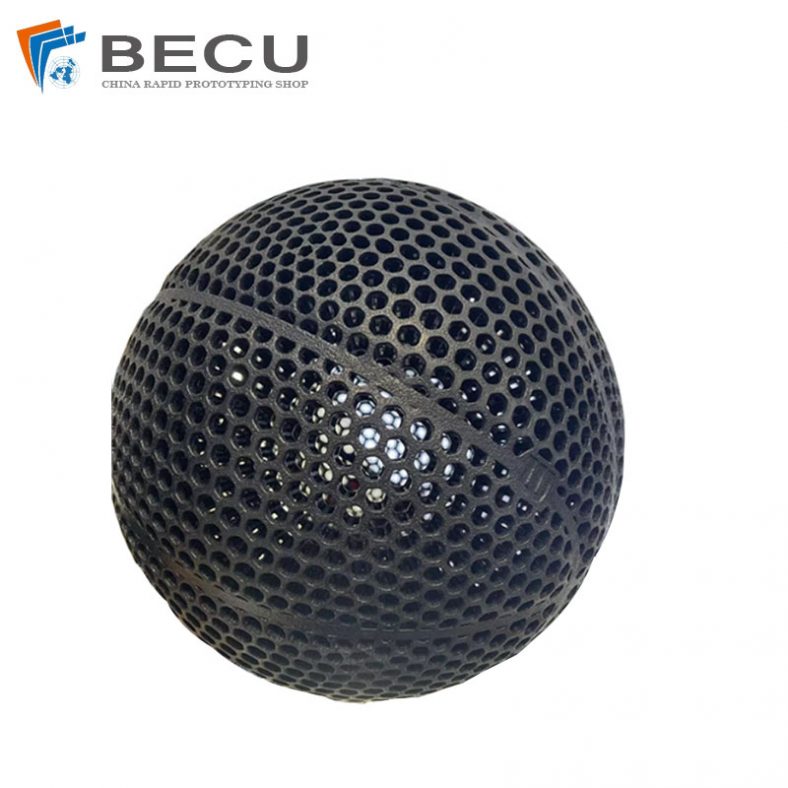

High-Quality Powder Sintering 3D Printed Shoe Midsole Sample

In recent years, due to the increase in population and the increase in residents’ disposable income, the demand for higher-end shoes has increased year by year. The sales volume of China’s footwear market is huge and growing steadily year by year. According to Euromononitor estimates, the average growth rate of China’s footwear market will remain above 7% in the next few years. The popularity of sports and the increase in national fitness awareness have caused sports shoes to enter a strong recovery period after adjustment. Major sports shoe brands around the world quickly seized the footwear market share and regained the market’s favor with functionality + fashion. Among them, 3D printing technology, which is said to bring about the third industrial revolution, has also been integrated into the production and design of footwear. Everyone thinks that high-tech 3D printing shoes are very novel, so as soon as they are launched on the market, they have won unanimous praise from the majority of users.

Adidas, which leads the sports trend, launched the 3D printed shoes “Futurecraft 4D” last year. This is a new pair of products that focus more on cutting-edge technology rather than fashion. The price is as high as US$300. Adidas CEO Caspar Rorsted It said that by the end of 2018, more than 100,000 pairs of Futurecraft 4D had been produced and sold, of which 10,000 pairs were allocated to the Chinese market. The sale price was 2,499 yuan. Only three days after it went on sale, the men’s model was sold out on the official website.

Coincidentally, at last year’s Beijing Marathon, Peak launched its own high-tech product – Yuepao 3D-PLUS running shoes. The upper of this running shoe uses an integrated weaving and blending process, and the midsole uses 500 fully hollow 3D printed lattice units. Composed with a gradient pebbled crystal outsole. The price on the official website is 1,399 yuan, and there seems to be no purchase limit this time, indicating that this 3D printed running shoe has been mass-produced.

In other words, sports shoes will have such a development trend in the future. They only need to use a 3D scanner to scan the user’s feet, collect their foot characteristics and various data, and then rely on the corresponding software to design a 3D rendering, and then use 3D Printing technology can customize running shoes. Such shoes can perfectly fit the user’s feet and are faster and more convenient.

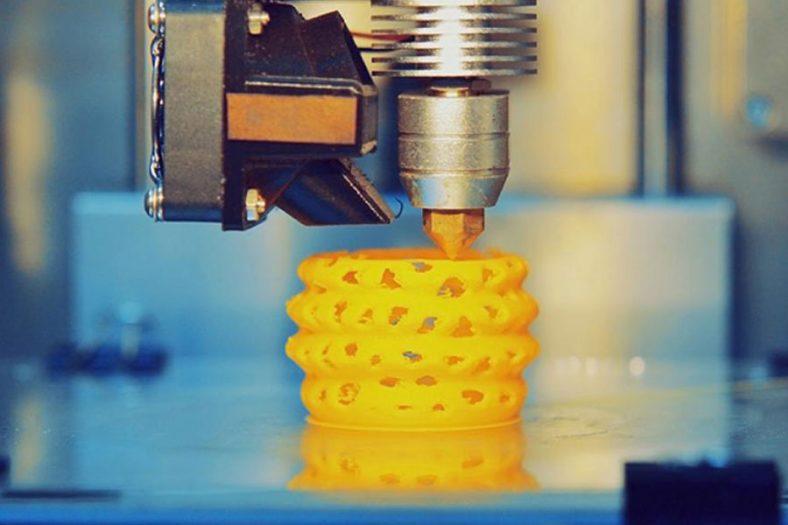

3D printing is a rapid prototyping manufacturing technology that constructs objects by stacking them layer by layer. It has very significant advantages in the design of sports shoes. The use of 3D printing technology can ignore the extremely complex structure, arbitrary curved hollow shapes and bite textures in the design, and directly use software to process it, and input the processed files into the 3D printing device. In just a few hours, samples can be quickly produced to achieve personalized production. Of course, after a thermal curing chemical reaction, which is equivalent to post-processing, the performance of the shoes will be greatly improved.

Most shoe mold customers provide samples, and then shoe mold manufacturers make molds based on the samples. The mold making process is not only cumbersome, but also tests the proficiency of the production equipment and operators. It is necessary to analyze and study whether the plastic products comply with the injection molding processing principle, and it is difficult to achieve the ideal effect.

3D printing can simplify complex processing processes. Based on three-dimensional data, products can be obtained quickly in the shortest time. Compared with traditional shoemaking processes, it is more intelligent and automated, and is labor-saving, efficient, precise, and flexible. Advantage. Although there is still some gap between large-scale mass production, 3D printing has penetrated in many aspects and is reshaping the entire shoemaking industry. Speed, efficiency, and personalization have formed a new round of competitive advantages that are obvious.

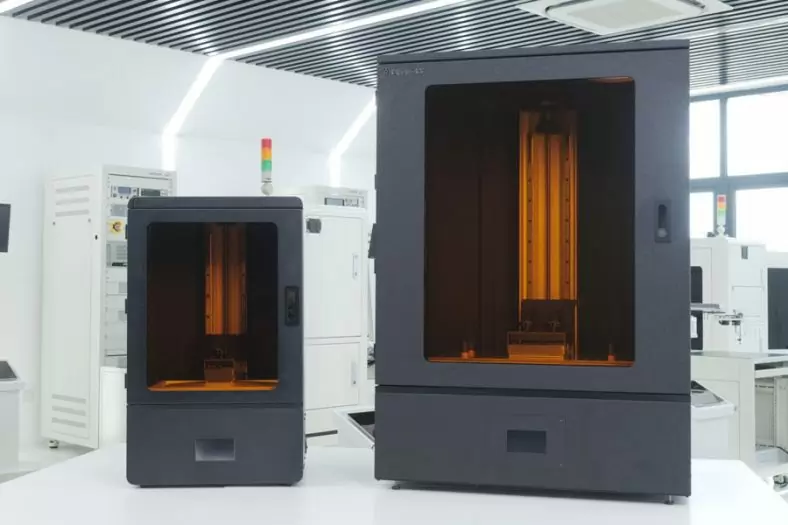

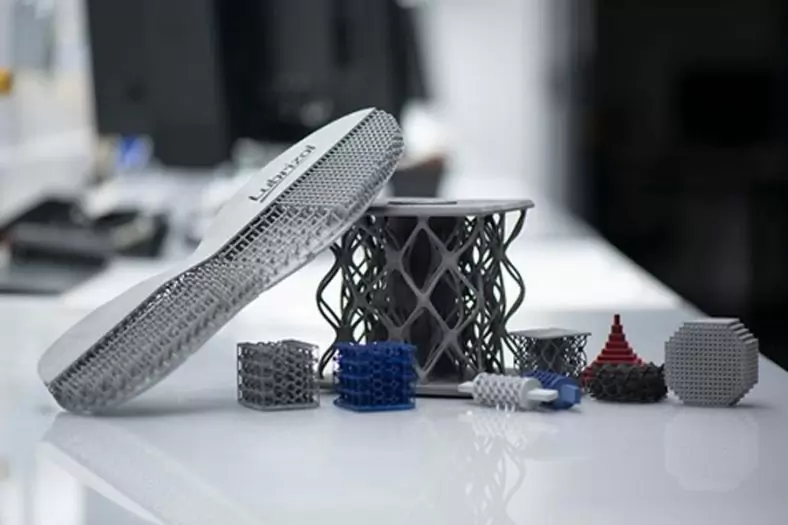

As a 3D printing technology innovator in China, BE-CU Prototype has independently developed five series of industrial-grade 3D printing product lines. Among them, the iSLA light-curing 3D printing system and the iSLS powder sintering 3D printing system can well carry out strategic cooperation with sports shoe manufacturers. , assisting in the development and design of high-performance 3D printed shoes, and has reached cooperation with many china footwear brands.

Why Choose Be-Cu Powder Sintering 3D Printed Shoe Midsole Sample Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

Specifications of Powder Sintering 3D Printed Shoe Midsole Sample

| Item Name | 3D Printing |

| Material | thermoplastics, polycarbonate, ASA, nylon12 CF and Ultem resin etc |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.