High-Quality Rapid Prototyping and 3D Printed Bike Light

A bike light is a lighting device designed to be mounted on a bicycle to enhance visibility during low-light conditions or nighttime riding. Bike lights serve several important purposes:

- Visibility: Bike lights help cyclists become more visible to drivers, pedestrians, and other road users. They emit light, making it easier for others to see the cyclist from a distance.

- Illumination: Bike lights illuminate the path ahead of the cyclist, making it easier to navigate in the dark and spot potential hazards, such as potholes, obstacles, or road debris.

- Safety: Properly functioning bike lights contribute to safety on the road by reducing the risk of accidents. They allow cyclists to signal their presence and intentions to other road users.

There are two main types of bike lights:

- 1. Front Lights: These lights are mounted on the front of the bicycle, typically on the handlebars or the front fork. Front lights provide illumination of the road ahead, allowing the cyclist to see where they are going.

- 2. Rear Lights: Rear lights are attached to the back of the bicycle, usually on the seat post, saddlebag, or rear rack. These lights emit red or amber light and are primarily used to make the cyclist visible from behind.

Here are some key features and considerations for bike lights:

- Brightness: Bike lights come in various brightness levels, measured in lumens. Brighter lights are generally more visible but may also consume more power.

- Beam Pattern: The beam pattern of a front light can vary from a focused spotlight to a broader floodlight. Some lights have multiple modes to adjust the beam pattern for different riding conditions.

- Battery or Power Source: Bike lights can be powered by disposable batteries (e.g., AA or AAA), rechargeable batteries, or built-in rechargeable batteries. Consider the runtime and ease of recharging when choosing a light.

- Mounting: Look for lights that are easy to attach securely to your bike. Quick-release mounts are convenient for removing the light when not in use.

- Modes: Many bike lights offer multiple lighting modes, including steady, flashing, and strobe modes. Flashing modes can enhance visibility, especially during daylight hours.

- Water Resistance: If you ride in wet conditions, choose lights with water-resistant or waterproof ratings to ensure they continue working in rain.

- Regulations: Be aware of local laws and regulations regarding bike lights, including required brightness levels and when they must be used (e.g., nighttime or low-light conditions).

Bike lights are an essential accessory for safe cycling, especially when riding in conditions with reduced visibility. Using both front and rear lights, along with reflective gear and accessories, can significantly improve your safety on the road.

How To Creating a 3D-printed bike light

Creating a 3D-printed bike light can be a fun and practical project that allows you to customize the design to your liking. Here are the general steps to create a 3D-printed bike light:

1. Design Your Bike Light:

Use 3D modeling software like Tinkercad, Fusion 360, Blender, or any other tool you’re comfortable with to design the bike light. Consider the following components:

- Housing for the light source (LED).

- Mounting brackets or clips to attach the light to your bike’s frame or handlebars.

- Space for batteries or a rechargeable power source.

- A switch or button for turning the light on/off.

- Wire channels for routing electrical wires neatly.

2. Choose Your Components:

Select the LED(s), batteries, wires, and any other electronic components you’ll need for the light. Ensure that they fit within the design you created. You may also want to consider adding a reflector for increased visibility.

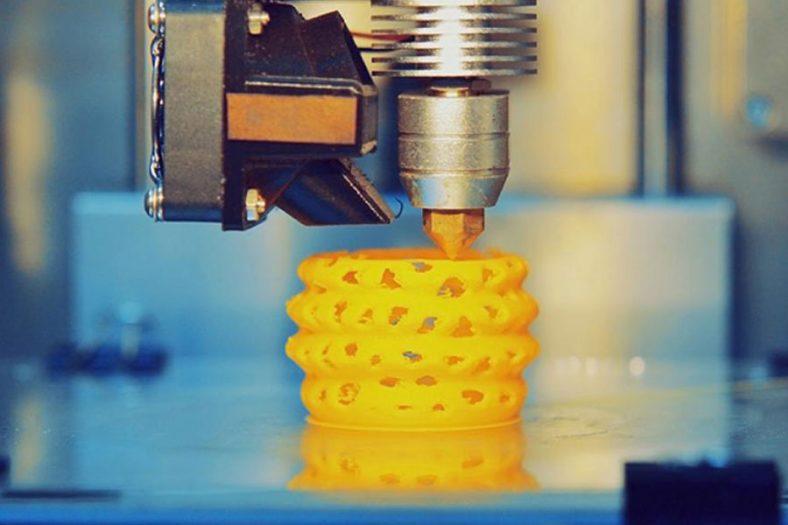

3. 3D Print Your Design:

- Once your 3D design is ready, export it in the appropriate file format (usually .STL or .OBJ) for 3D printing.

- Use a 3D printer with the desired material (e.g., PLA, ABS) to print the different parts of your bike light.

- Be sure to adjust printer settings like layer height and infill density based on your design and material choice.

4. Assemble the Components:

- After 3D printing, clean up any rough edges or imperfections in the parts.

- Assemble the LED(s), batteries, wires, switch, and any other components according to your design. Pay close attention to the electrical connections and ensure they are secure and functional.

5. Test the Light:

Before finalizing the assembly, test the bike light to make sure it works as expected. Check for any issues with the wiring, switch, or LED brightness.

6. Secure the Light to Your Bike:

Use the mounting brackets or clips you designed to attach the bike light to your bicycle securely. Ensure it’s positioned in a way that provides good visibility while riding.

7. Finalize and Finish:

- If desired, you can add paint or coatings to the 3D-printed parts to improve aesthetics and durability.

- Make any final adjustments to the light’s position or settings.

8. Safety Considerations:

- Ensure that your bike light does not interfere with your ability to safely operate your bicycle.

- Consider making the bike light detachable for charging or maintenance.

9. Enjoy Your Custom Bike Light:

Once everything is in place and working correctly, you can enjoy your custom 3D-printed bike light on your rides.

Remember that safety should be a top priority when designing and using a bike light. Ensure that it is bright enough to make you visible to others on the road, and follow local laws and regulations regarding bike lights and reflectors. Additionally, consider waterproofing your design if you plan to use it in wet conditions.

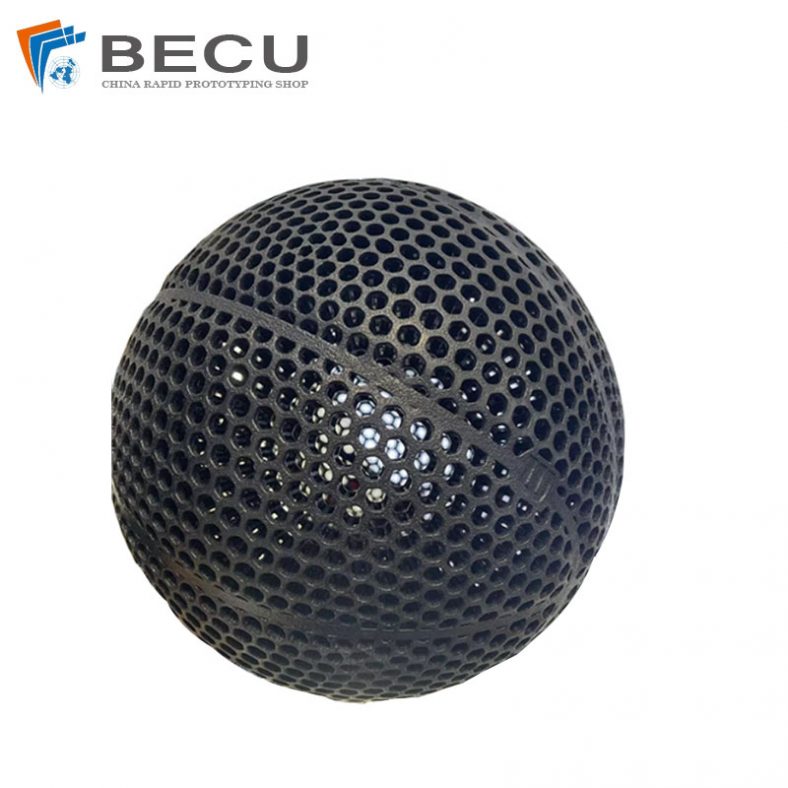

Be-Cu prototype is a Rapid Prototyping and 3D Printed Bike Light and advanced digital manufacturing service provider with ISO 9001-2015 accreditation committed to consistently producing goods and customised services that meet client’s needs and comply with legal regulations. If you require manufacturing services using materials that are not on the material list, our staff will make the necessary effort to obtain the supplies without requiring a minimum order quantity (MOQ).

Why Choose Rapid Prototyping and 3D Printed Bike Light Service?

- – No minimum order quantity

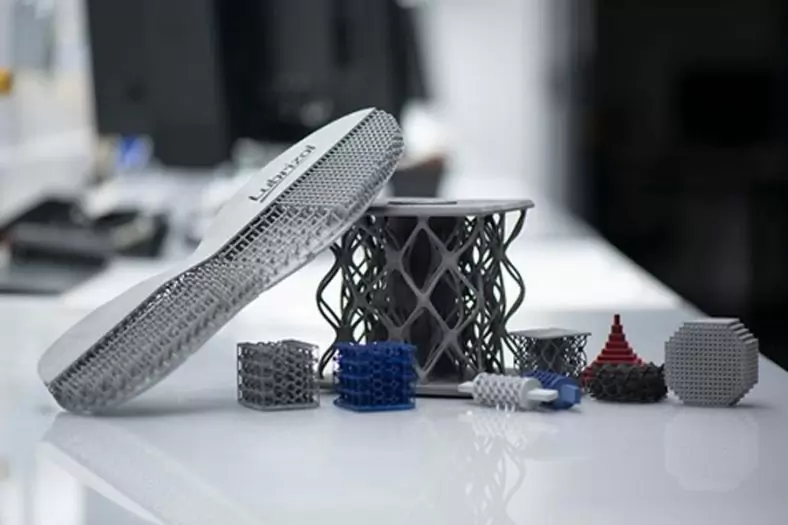

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

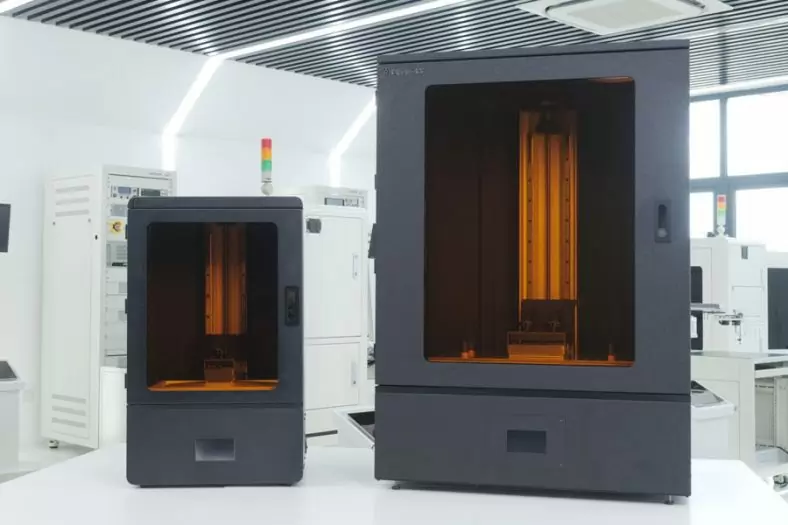

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of Rapid Prototyping and 3D Printed Bike Light

| Item Name | PMMA 3D Printing |

| Material | PMMA |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.