Valve Seat

- No.: Tungsten Machining

- Color: Custom

- Surface Treatment: Custom

- Product Material: Tungsten Cobalt Carbide

- Proofing Cycle: 7 days(100000 pcs/M)

- Accuracy: 0.005mm

- Hardness: 58-62

- Squareness: 100mm

- Product Category: Oil and Gas Machining Parts

- Production Process: Sintering

- Size: According To Customer’s Drawings

High-Quality CNC Machining Oil And Gas Carbide Tungsten Valve Seat

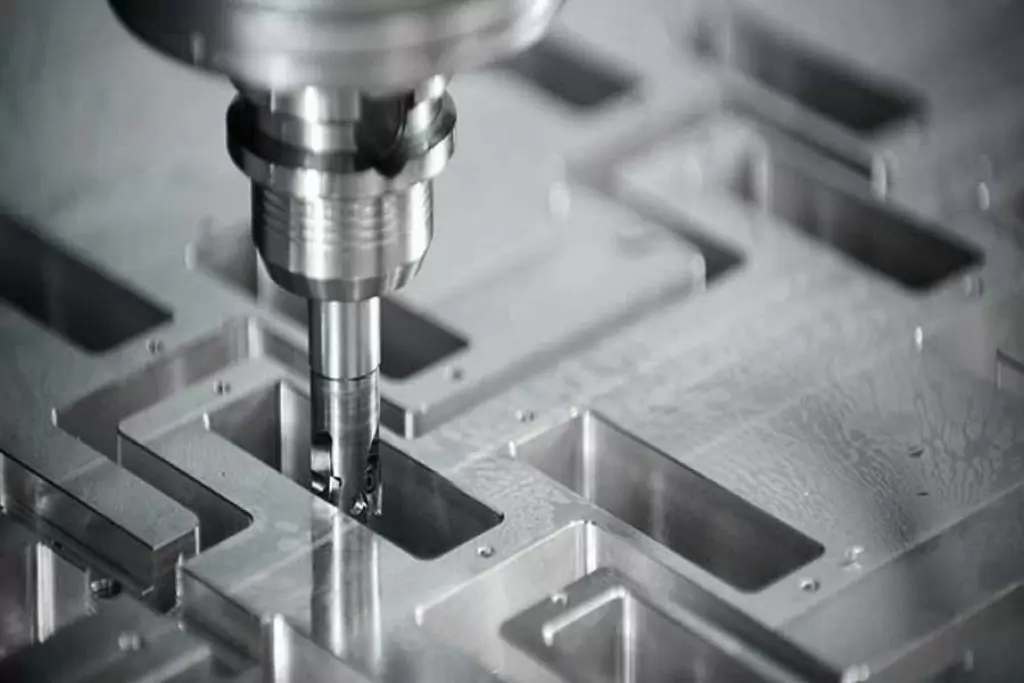

Valve seats play a crucial role in maintaining a tight seal within the valve. Carbide tungsten valve seats provide excellent sealing properties, preventing leakage and ensuring efficient fluid control.Valve seats are subjected to constant wear and erosion due to the abrasive nature of oil and gas fluids. Carbide tungsten valve seats exhibit superior wear resistance, which prolongs the lifespan of the valve and reduces maintenance requirements.Carbide tungsten valve seats are essential components used in the oil and gas industry, particularly in valves and wellhead equipment. Carbide tungsten valve seats are used in various types of valves, including gate valves, globe valves, ball valves, and check valves. They are compatible with a wide range of fluids, from crude oil to natural gas.These valve seats are designed to withstand extreme conditions, including high-pressure, high-temperature, and corrosive environments.

Carbide tungsten valve seats are manufactured with high precision to meet the specific requirements of different valve types and applications. This ensures that they fit and perform reliably in various systems.Be-Cu prototype is a China top carbide CNC machining company that fabricates quality Carbide tungsten valve seats machined parts as your request. Valve components used in the oil and gas industry must often meet strict regulatory standards for safety and environmental protection,we can provide cost-effective solutions for industries ranging from oil and gas industry and more.Contact us via [email protected] to complete your valve seat project!

The Advantages Of CNC Machining Oil And Gas Carbide Tungsten Valve Seat

- Extended Tool Life: Due to its outstanding wear resistance, the punch maintains sharpness and accuracy over an extended period, reducing the need for frequent replacements.

- Increased Productivity: The precision CNC machining ensures efficient and consistent performance, leading to enhanced productivity and reduced production lead times.

- Improved Cost-effectiveness: With its prolonged tool life and minimal maintenance needs, the CNC Machining Tungsten Cobalt Carbide Punch offers cost-effective solutions for high-volume manufacturing processes.

Specifications of CNC Machining Oil And Gas Carbide Tungsten Valve Seat

| Material | Tungsten Cobalt Carbide alloy |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

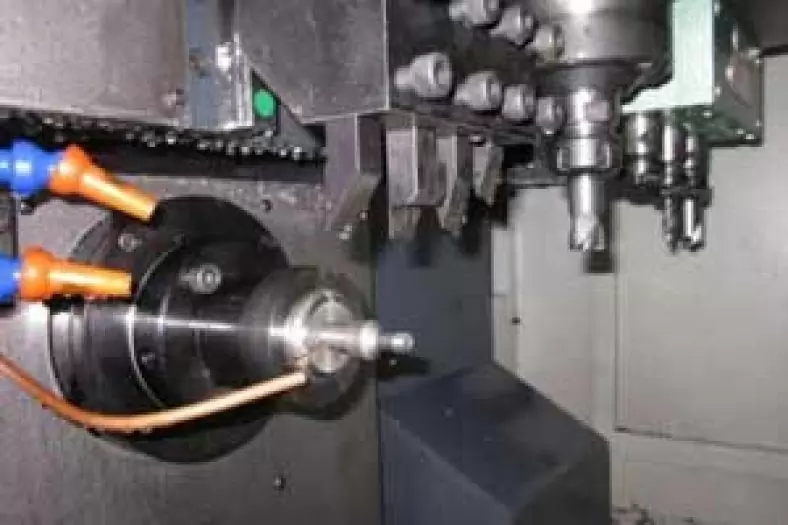

| Main Process | Cnc Turning,EDM Machining,Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Electronic |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]