Cnc Machining For Inconel – What Is Inconel Cnc Machining

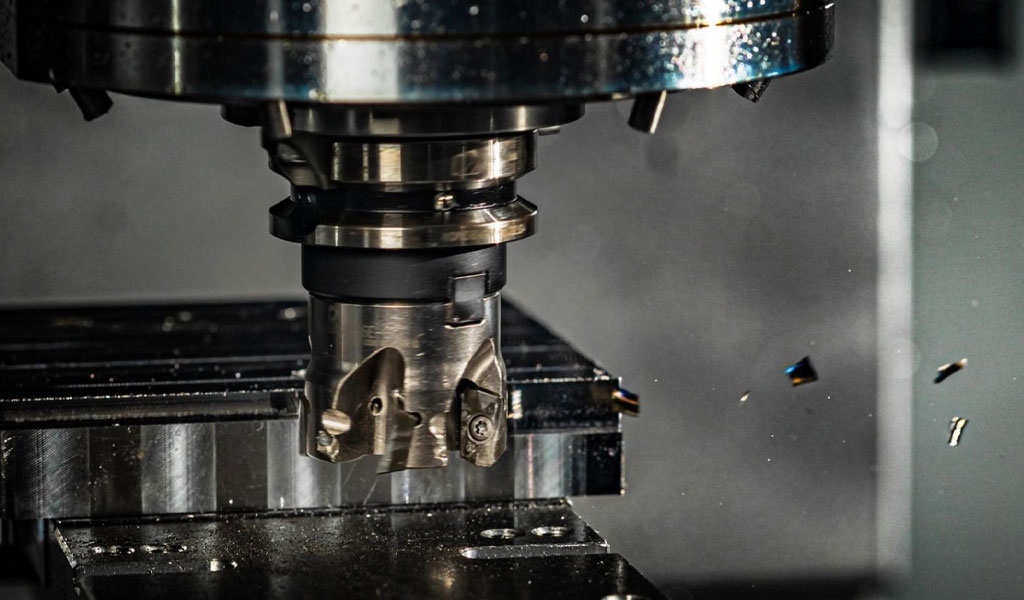

Inconel CNC machining refers to the process of using Computer Numerical Control (CNC) technology to precisely cut, shape, or mill Inconel, a family of high-performance nickel-chromium-based superalloys. Inconel alloys are known for their exceptional properties, including high temperature resistance, corrosion resistance, and excellent mechanical properties across a wide range of temperatures.

CNC machining involves using computer-controlled machinery to accurately remove material from a workpiece according to programmed instructions. This process allows for high precision and repeatability in manufacturing parts or components from Inconel materials.

Benefits Of Inconel Alloy Material

Inconel alloys offer several significant benefits due to their unique combination of properties, making them highly valuable in various industries, especially where high temperature, corrosion resistance, and strength are crucial. Some of the key benefits of Inconel alloy materials include:

- High Temperature Resistance: Inconel alloys are renowned for their exceptional resistance to high temperatures and thermal stability. They retain their strength and structural integrity at elevated temperatures, making them ideal for applications in extreme heat environments such as gas turbine engines, aerospace components, and industrial furnaces.

- Weldability and Fabrication: Inconel alloys are generally weldable and can be easily fabricated using various methods such as forging, machining, and forming. This versatility in fabrication processes allows for the production of complex components and structures.

- Oxidation Resistance: Inconel alloys have exceptional resistance to oxidation, which prevents the formation of oxides and scale at high temperatures. This property contributes to their longevity and reliability in high-temperature applications.

- Versatility in Applications: Due to their exceptional properties, Inconel alloys find application in various industries such as aerospace, marine engineering, chemical processing, gas and oil extraction, nuclear reactors, and other high-temperature and corrosive environments.

- Corrosion Resistance: Inconel alloys exhibit excellent corrosion resistance in harsh environments, including exposure to acids, seawater, chemicals, and oxidizing agents. This resistance to corrosion makes them suitable for chemical processing, marine applications, and environments with aggressive substances.

- Strength and Toughness: These alloys possess high strength and toughness even at high temperatures. They maintain their mechanical properties under extreme conditions, making them suitable for critical structural components in industries like aerospace, nuclear, and petrochemical.

- Creep Resistance: Inconel alloys demonstrate resistance to creep deformation, which is the gradual deformation of materials under constant stress at high temperatures. This property is crucial in applications where sustained high temperatures and loads are present.

- Reliability and Longevity: Components made from Inconel alloys tend to have a longer service life due to their resistance to environmental degradation, thermal stability, and mechanical strength.

Inconel alloys are highly prized for their unique combination of high-temperature resistance, corrosion resistance, strength, and durability. These properties make them indispensable materials for critical applications in industries where performance under extreme conditions is paramount.

Machining Inconel Suppliers – Custom 5 Axis CNC Milling Inconel Alloy

If you’re looking for a readily available metal with a high strength-to-weight ratio and good machinability, Inconel could be the right choice for your project. In addition, you should opt for Inconel if your part or component will be exposed to moist environments since Inconel alloys are generally resistant to corrosion.

But even after you take the plunge with Inconel for your project, you still need a high level of CNC machining expertise to create your parts accurately and precisely.

BE-CU Prototype can handle all types of metal cnc machining projects no matter they are related to 5-axis CNC milling inconel, 3-axis CNC milling inconel, inconel parts turning,inconel 3d printing or whatsoever. You can get complex CNC machines parts and high precision inconel parts. We offer advanced 5-axis Milling inconel to enhance the range of various inconel parts and provide you with excellent surface finish and tight tolerance to satisfy the fabrication and production challenges of a new era. We will always do our best to meet your design and manufacturing needs, and help your ideas come to life.

Inconel Machinability

Inconel alloys, known for their excellent high-temperature and corrosion-resistant properties, present challenges in terms of machinability due to their characteristics.

Despite its challenges, machining Inconel is possible with the right tools, techniques, and expertise.Machining Inconel can be difficult compared to machining other materials due to the following reasons:

- Hardness: Inconel alloys are typically harder materials, which can lead to increased tool wear and shorter tool life during machining operations.

- High Strength at Elevated Temperatures: These alloys maintain their strength even at high temperatures, making them tough to cut or machine without specialized tooling and machining techniques.

- Work Hardening: Inconel materials tend to work-harden quickly during machining. This can result in increased cutting resistance, making it challenging to achieve precise cuts and maintain consistent surface finishes.

- Heat Generation: Machining Inconel generates a significant amount of heat due to its high-temperature resistance. This heat can adversely affect tool life and dimensional accuracy if not managed properly.

- Abrasive Nature: Inconel alloys often contain elements that can make them abrasive during machining, causing additional wear on cutting tools.

Inconel Material Grades We Work With

Many kinds of material could be used for CNC machining,you could choose the most suitable materials for your project.BE-CU Prototype could handle inconel alloy materials

Inconel 600 Machining

Inconel 625 Machining

Inconel 718 Machining

Inconel X-750 Machining

Advantages Of Inconel Machining

- Great precision and high tolerance ensure high-quality Inconel parts

- Time and cost-saving, great speed of Machining Inconel part

- Allows products ordered to be made precisely to the specifications stated

- Complex Inconel parts for high tech industry can be machined

Why Choose Our Inconel Cnc Machining Service?

- Save time and money for your Inconel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of Inconel grades and alloy materials can be machined

- Custom complex Inconel machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Inconel Cnc Machining Case Studies

Whether you require machined Inconel prototypes or custom Inconel parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in CNC Inconel machining and the ability to integrate external combined processes, we can ensure the best performance for your machining Inconel projects.Understanding the properties of different Inconel alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on Inconel alloy. Be-cu prototyping company provides a range of solutions for the machining of Inconel parts.