The development of human civilization and the progress of society are closely related to metal materials. The Bronze Age and the Iron Age appeared after the Stone Age. All of them are marked by the application of metal materials. In modern times, a wide variety of metal materials have become an important material basis for the development of human society. Metal refers to a material with properties such as luster, ductility, easy electrical conductivity, and heat transfer. Generally divided into two kinds of ferrous metals and non-ferrous metals.Ferrous metals include iron, chromium, manganese, etc. Non-ferrous alloys are alloys composed of a non-ferrous metal as the matrix (usually more than 50%) and adding one or several other elements. Non-ferrous metals generally refer to all metals except iron (and sometimes manganese and chromium) and iron-based alloys.

Non-ferrous metals can be divided into heavy metals (such as copper, lead, zinc), light metals (such as aluminum, magnesium), precious metals (such as gold, silver, platinum) and rare metals (such as tungsten, molybdenum, germanium, lithium, lanthanum, uranium).

Metal Machining Services – CNC Machining Metal Parts Shop

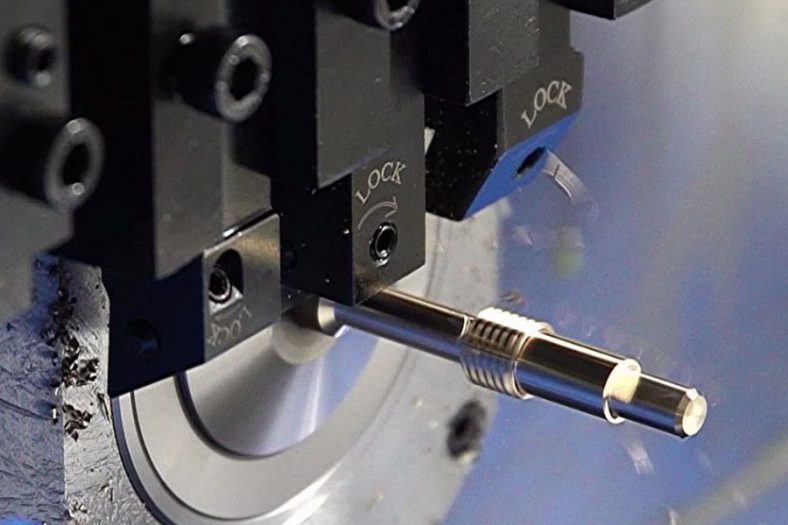

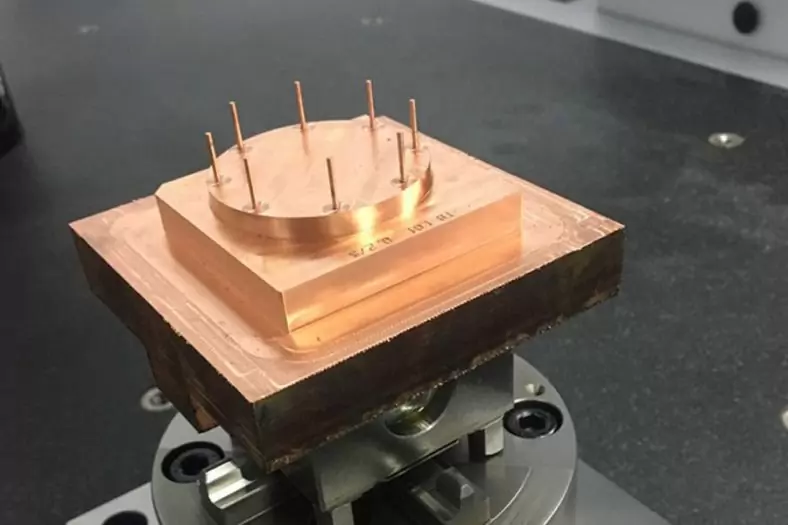

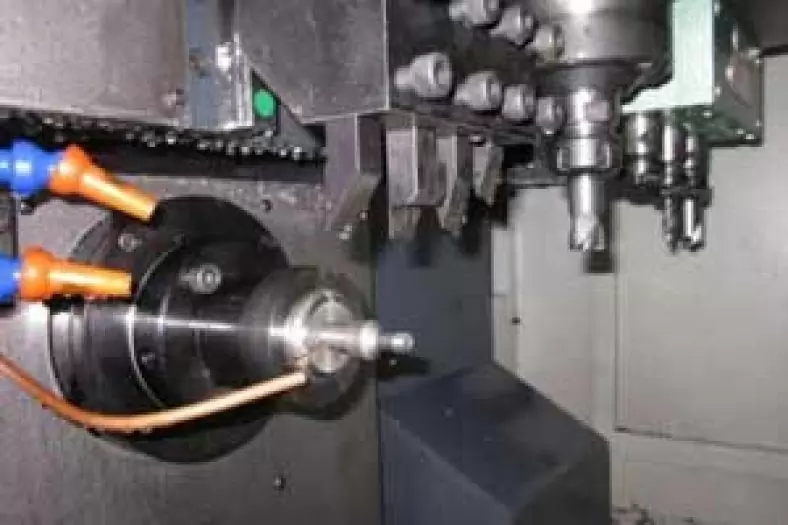

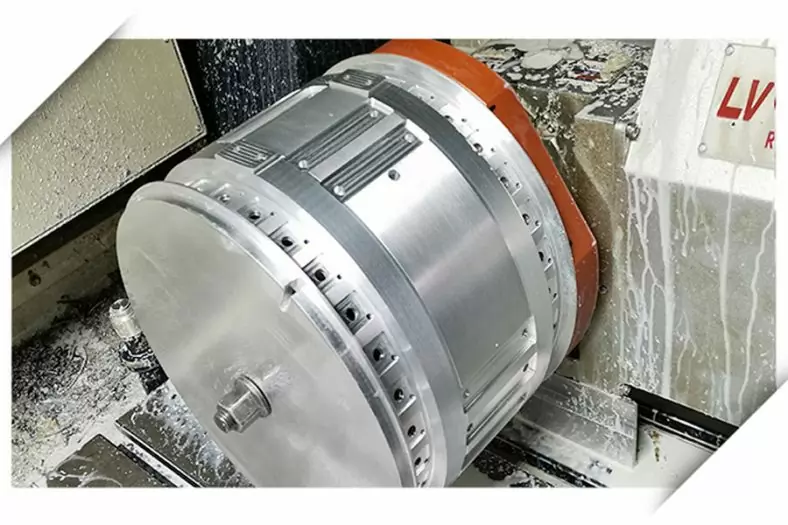

At BE-CU metal machining shop, we take pride in our state-of-the-art CNC metal machining services and our specialized routing equipment, which allows us to deliver high-quality cnc machining metal components machined to our clients’ standards.

Our team of expert metal CNC machinists are skilled at creating parts that fit tight tolerances and are consistently produced over high volumes.

Providing complete solutions for your engineering and CNC metal Part Machining needs through our precision CNC metal machining shop. Our established in-house CNC machining capabilities provide our customers with quality machined parts. We create CNC programs directly from customer files or drawings which ensure accuracy of all finished parts – from simple cuts to complex shapes, dual head and single head machines cut nested parts very efficiently. Read more about our metal CNC machining services below.

Why Choose Our Metal Cnc Machining Service?

- Save time and money for your metal project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of metal grades and alloy materials can be machined

- Custom complex metal machining parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Metal Material Of Precision Cnc Machining

Metal material can be easily machined and have a low raw material cost, making them often the most economical choice for prototyping and cnc machined metal parts.There are a few factors to consider when choosing the right metal for CNC machining. The metal you choose is critical to your ultimate success. For example, metals may need to withstand high temperatures or bend or break under pressure. When choosing the right metal, corrosion resistance, machinability, price, weight and visual appearance all play a role.

Top China Metal Cnc Machining Parts & Case Studies

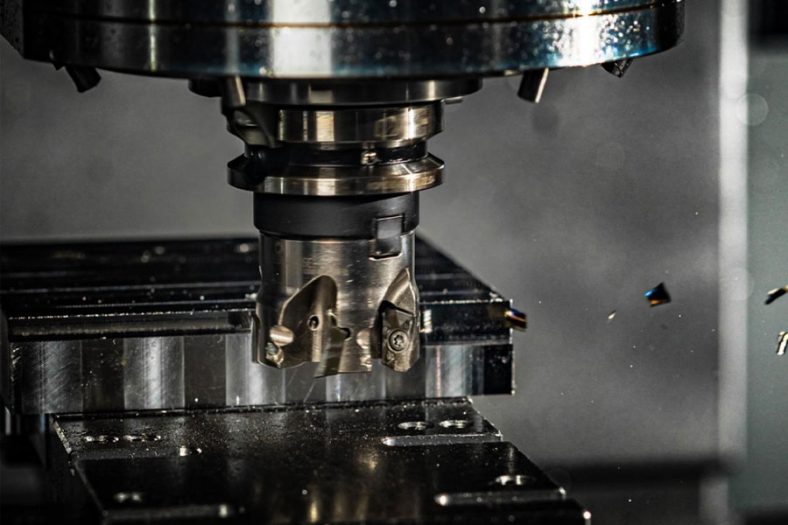

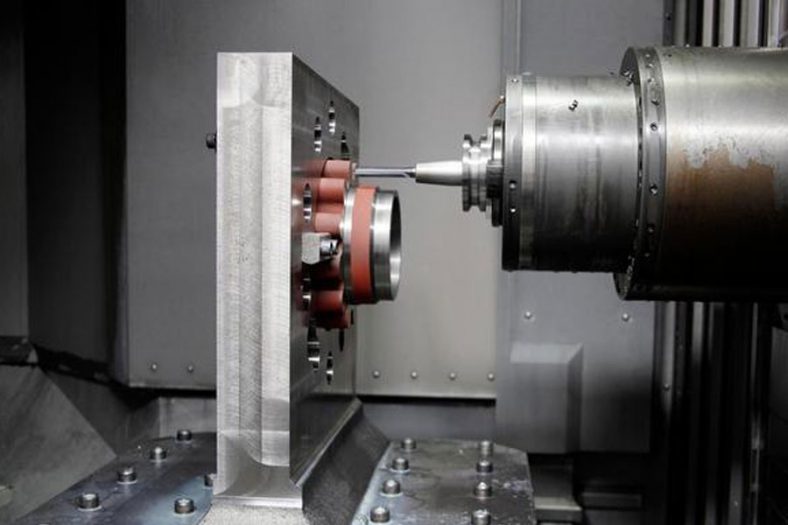

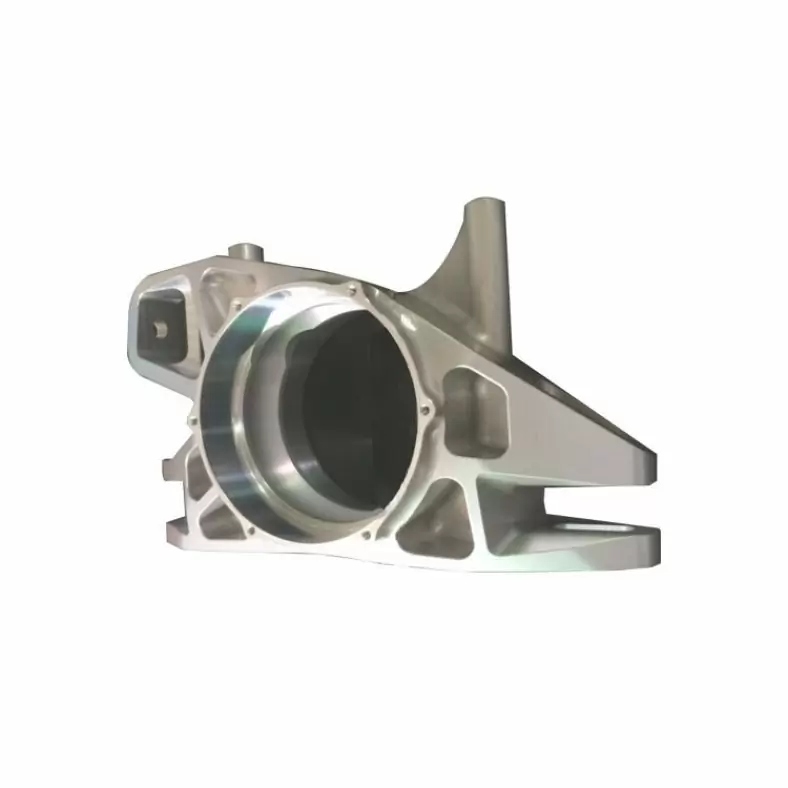

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make metal prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making metal concept models and precise functional components. Understanding the properties of different metal material, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on metal material. Be-cu prototyping company provides a range of solutions for the machining of Metal Parts.

-

5 Axis Cnc Machining Titanium Motorcycle Frame

-

Custom Stainless Steel Marine Deck Screws

-

Aluminum Alloy Automotive Signal Shield Shielding Cavity

-

CNC Machining Military-grade Electronic Housing

-

Custom Smart Audio Shell Parts And Base

-

Metal Control Panel Electronic Enclosure

-

Metal Control Panel Electronic Base

-

6061-T Industrial Control Notebook Housing

-

Aluminum 6061-T Optoelectronic Communication Product Housing

-

LCD Display Shell By Cnc Machining

-

MTB Positive And Negative Disc-Brake

The Methods Of Metal CNC Machining

What Is Metal Machining – The Define Of Metal Processing

The progress of human society is closely related to the processing and application of metal materials. Brass was smelted more than 6,000 years ago, simple bronze tools were made more than 4,000 years ago, and meteorite iron was used more than 3,000 years ago. Weapons, China has been smelting pig iron in the Spring and Autumn Period more than 2,500 years ago, more than 1,800 years earlier than Europe. In the 18th century, the development of the iron and steel industry became an important content and material basis for the Industrial Revolution. Metal processing refers to the production activities in which human beings process materials with metallic properties composed of metallic elements or mainly composed of metallic elements. It is a process technology for machining metal materials into objects, parts and components, including large parts such as bridges and ships, and even small components of engines, jewelry and watches. It is widely used in different fields such as science, industry, art, handicraft and so on.

CNC Machined Soft And Hard Metals Alloy

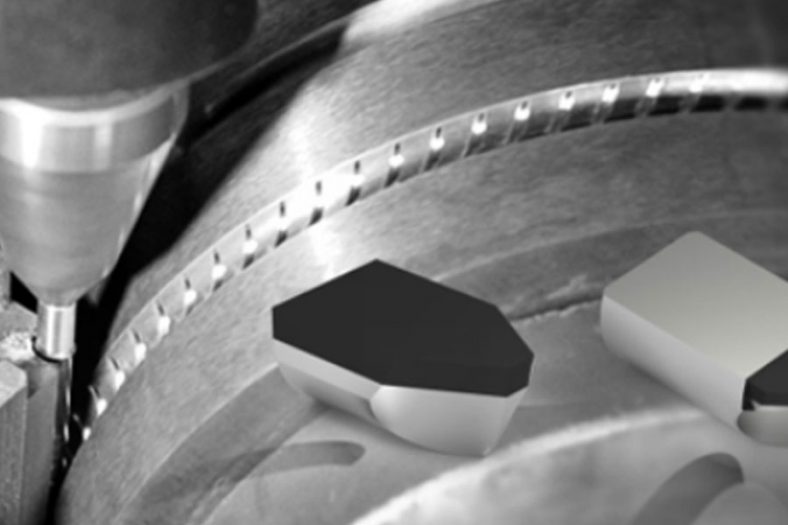

Let’s start with mechanical properties, which are measured by how a material behaves when different forces are applied. The main mechanical properties of metals to consider are: strength (hard metals), ductility (soft metals), elasticity (hard metals tend to be more elastic than soft metals), hardness (hard metals), density (density ranges from soft to hard) , magnetism (steel), fracture toughness (the largest range of fracture toughness of all metals, but the hardest from soft to hard), damping (hard metals tend to have less damping capacity).

Wear And Fatigue Strength Of Metals

In general, if you’re CNC machining a part for prototype fit and function, then you don’t need to worry about material wear. If you need to ensure that strength or parts can withstand environmental performance tests such as extreme temperatures, then we should pay great attention to the choice of materials. Let’s break down the most important fatigue properties.

- Fatigue Strength and Toughness: This is the stress a material can withstand under a specific number of cycles. These variations have been extensively researched to assist in the proper selection of materials to meet your end-use requirements. In fact, according to research on this topic, “it is estimated that about 90 percent of failures in metals are caused by fatigue.” Failures occur quickly and without warning, so we usually measure fatigue strength by ratio averages . When selecting a material, it is recommended to evaluate a fatigue strength rating if you know that the part will be subjected to multiple stress cycles.

- Ambient Loops: There are many resources for ambient loop testing. In most cases, materials are placed in a controlled environment and tested for high and low temperatures, high and low humidity, thermal cycling and thermal shock, among others.High temperature metals: titanium and stainless steel.-Metals that can withstand extremely cold temperatures and retain their toughness at low temperatures: copper and aluminum.

Corrosion (Oxidation) Resistance Of Metals

All things on earth, whether they are people or stones, are in a process of anti-oxidation, and the same is true for metals. Metal corrosion is the result of chemical reactions between metals and the surrounding environment, which is degradation or oxidation. Basically all metals will be oxidized and corroded, but different metals have different structures, so the corrosion resistance is also different. Pure iron usually corrodes quickly, but stainless steel combines iron and other alloys, and the corrosion rate is very slow. If you are concerned about corrosion, stainless steel is a good metal choice.

Manufacturability Of Metals

When it comes to manufacturability, each supplier or manufacturing partner can have a different set of requirements based on their capabilities. If you find that your part cannot be cnc machined and your part design has little flexibility, you may need to change your manufacturing method to 3D printing, which can provide unique solutions in metals and plastics.

The Cost Of CNC Machining Metal

Finally, and most importantly, we pay attention to the cost of the materials you choose. This may not come as a surprise to you, but if you have more material requirements or needs then you will most likely pay more for those materials. Aluminum is an affordable machined material, and we talked about it above. We recommend referencing your DFM to optimize your part design, saving you time and money, regardless of your material choice.