Cnc Machining For Kovar – What Is Kovar Cnc Machining

Kovar is a nickel-cobalt ferrous alloy known for its excellent thermal expansion characteristics that match certain types of glass and ceramics.

It’s commonly used in applications where a hermetic seal between metal and glass or ceramic is required, such as in electronics, telecommunications, and aerospace industries.

Kovar has properties that can make it challenging to machine. Its high nickel content can cause work hardening, leading to increased tool wear. Therefore, using carbide tools with proper coatings or other tool materials designed for machining difficult materials can be beneficial.

Kovar tends to be brittle, and stress relief processes might be needed after machining to avoid potential dimensional changes or cracking due to internal stresses.Due to Kovar’s properties, CNC machining it can be more challenging compared to machining softer materials. Manufacturers often have to balance between achieving accurate dimensions, maintaining surface finish, and prolonging tool life.

Benefits Of Kovar Material

Kovar is a specialized alloy that offers several benefits, especially in applications requiring a reliable hermetic seal between metals and glass or ceramics. Some of the key advantages of Kovar include:

- Low Expansion Characteristics: Kovar has a near-linear coefficient of thermal expansion, making it match well with certain types of glass and ceramics. This property is crucial in applications where a strong, hermetic seal is required between different materials with varying expansion rates, such as in electronic and semiconductor packaging.

- Stability Over a Wide Temperature Range: Kovar maintains its dimensional stability across a broad temperature range, making it suitable for use in environments that experience extreme temperature fluctuations.

- Weldability: Kovar is weldable, allowing for the assembly of different parts or the attachment of Kovar components to other materials, which is essential in various manufacturing processes.

- Corrosion Resistance: Kovar exhibits good resistance to corrosion, particularly in environments encountered in electronic and aerospace applications.

- Hermetic Sealing: Its compatibility with glass and ceramics makes Kovar an ideal choice for creating reliable hermetic seals. This is particularly important in electronic and electrical applications where protection from moisture, gases, and other environmental factors is necessary.

- Machinability: While Kovar can present challenges during machining due to its hardness and tendency to work harden, it can still be machined with proper tools and techniques, allowing for precision manufacturing of complex components.

- Electrical and Magnetic Properties: Kovar possesses good electrical conductivity and is non-magnetic at normal temperatures. This makes it suitable for electrical contacts and components where magnetic interference needs to be minimized.

- Reliability: Its compatibility with glass and ceramics, along with its stability in different environments, contributes to the overall reliability of devices and systems where Kovar is used.

While Kovar offers these advantages, its specific usage depends on the requirements of the application. Its unique properties make it a preferred material in industries such as electronics, telecommunications, aerospace, and medical devices where a reliable hermetic seal and dimensional stability are crucial. However, its cost and the challenges associated with machining should also be considered when selecting materials for a particular application.

Machining Kovar – Custom CNC Machining Kovar Alloy Manufacturer

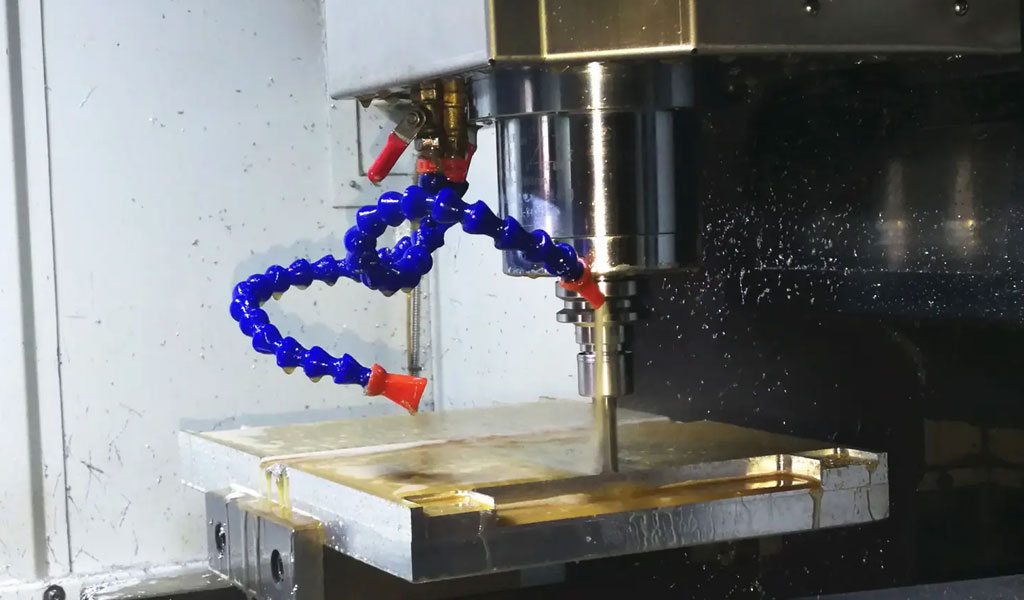

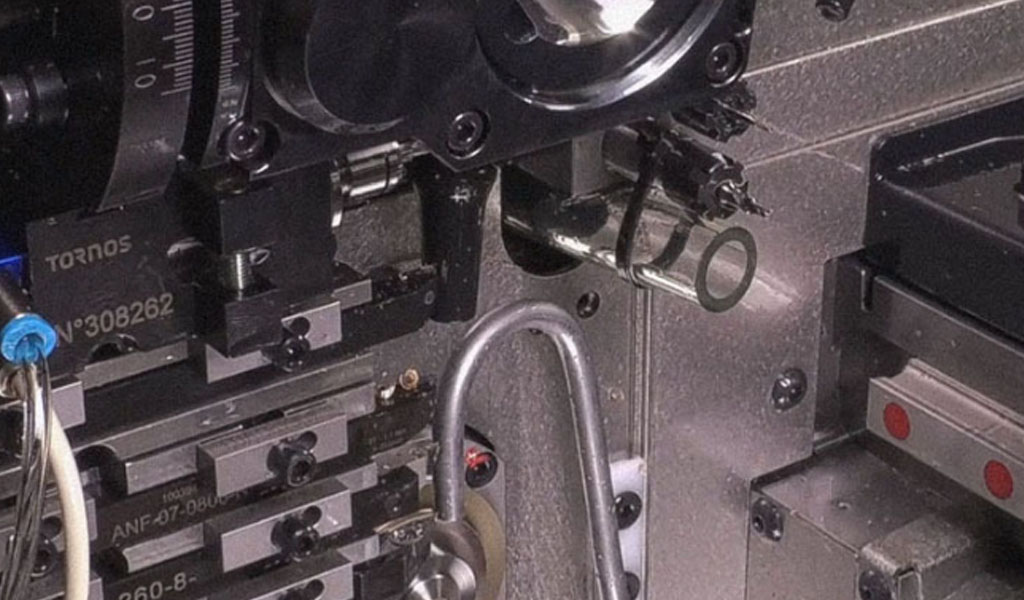

While Kovar can present challenges during metal machining due to its hardness and tendency to work harden, it can still be machined with proper tools and techniques, allowing for precision manufacturing of complex components.If you need assistance on your custom Kovar machining projects, we will be one of the most capable and affordable production sources with our technology, experience, and skills. Our strict implementation of ISO9001 quality system standards, and the combination of efficient production processes and flexible custom engineering enable us to deliver complex projects in short turnaround times and provide excellent product quality.

Our engineering team will review each kovar project, analyze your design and meet any special needs such as a combination of welding, EDM, or wire EDM processes. This in-depth validation ensures you receive the most effective machining processes for your budget, time, and materials. We also provide typical surface treatment operations for custom Kovar parts, such as sandblasting, shot blasting, polishing, electrophoresis, chromating, powder blasting, painting, etc.

Kovar Machinability

CNC machining of Kovar involves working with a specific type of material known as Kovar alloy. Kovar’s unique properties, including its thermal expansion characteristics and compatibility with glass and ceramics, make it a preferred material in industries such as electronics, telecommunications, aerospace, and medical devices. The composition of Kovar typically consists of approximately 29% nickel, 17% cobalt, 53% iron, and trace amounts of other elements like manganese, silicon, and carbon.

Advantages Of Kovar Machining

- Great precision and high tolerance ensure high-quality Kovar parts

- Time and cost-saving, great speed of Machining Kovar part

- Allows products ordered to be made precisely to the specifications stated

- Complex Kovar parts for high tech industry can be machined

Why Choose Our Kovar Cnc Machining Service?

- Save time and money for your Kovar project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of Kovar grades and alloy materials can be machined

- Custom complex Kovar machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Kovar Cnc Machining Case Studies

Whether you require machined kovar prototypes or custom kovar parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in CNC kovar machining and the ability to integrate external combined processes, we can ensure the best performance for your machining kovar projects.Understanding the properties of different Kovar alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on Cast Iron alloy. Be-cu prototyping company provides a range of solutions for the machining of Kovar parts.