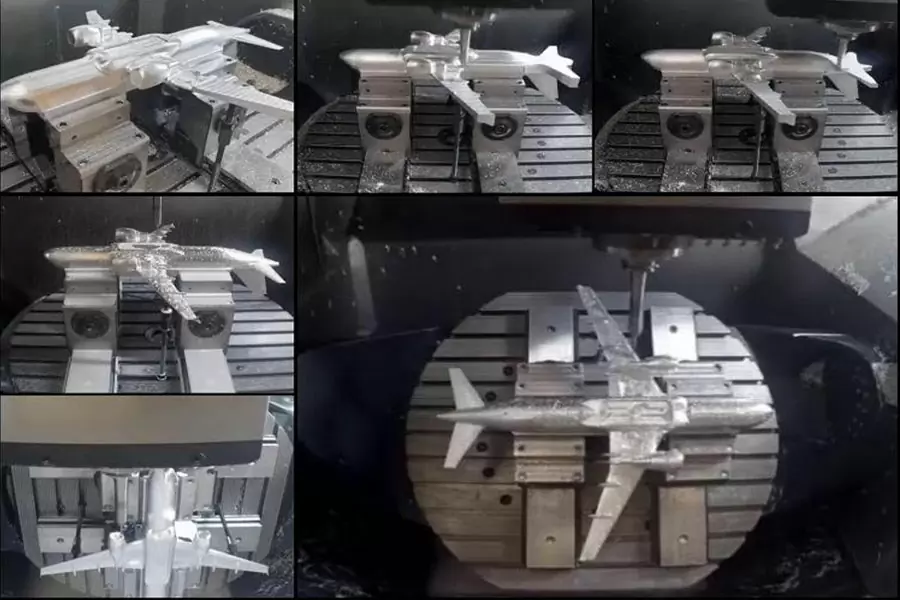

5 Axis Machining

- Global delivery as fast as 10 days,Machined prototypes in as fast as 1 days.

- 100+metals and plastics

- Tolerances down to +-0.001mm

- ISO 9001:2015, ITAF 16949

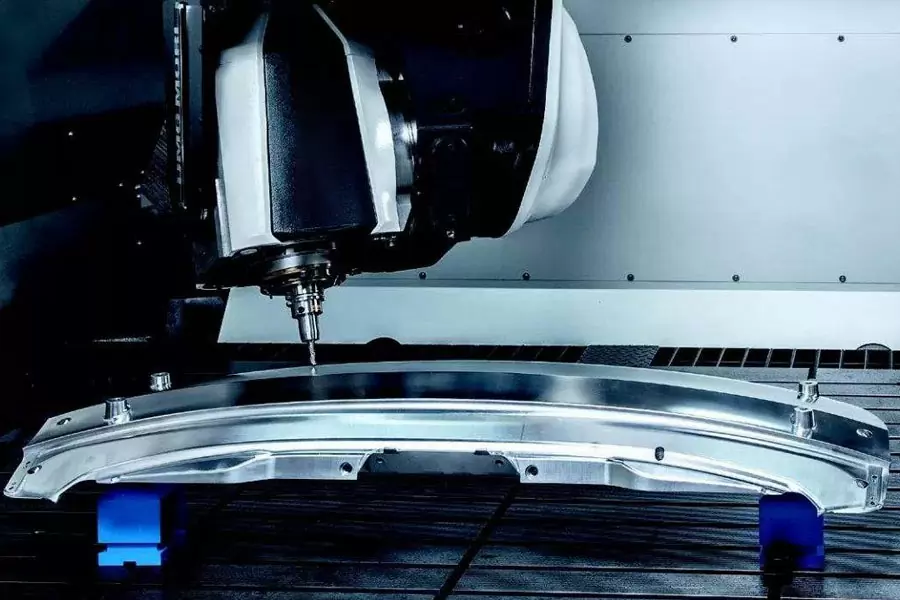

- With 6 sets of 5-axis machines in house, DMG And Mazak,3+2 etc.,

Unlock complexity and precision for all your machining needs

China Top 5 Axis Machining Service Parts Supplier & Manufacturer

As an experienced and professional machine shop specialized in CNC manufacturing for 30 years, Be-cu is capable of precision 5 axis CNC machining services and 5 axis milling.As a continuously selected factory by medical, semiconductor and other enterprises,Whether you are in need of high-quality and precise metal or plastic components, we can provide 5 axis machining parts to worldwide clients for a variety of industries including automotive, medical, military, aerospace, mechanical, machine tool, high-tech, and more, with excellent machining and programming skills, as well as 5 axis CNC machining center. Our engineers and machinists can perform true 5 axis machining services work and produce five axis machining parts with ease. Raw material procurement, production and processing, measurement, inspection, shipping one-stop production system, flexible response to delivery time and price. In addition, through the design and manufacture of fixture by our own company, while ensuring the required accuracy, we can reduce the number of processes and commissioning time, and reduce the mass production cost. If you require a well-established and cost-effective CNC machining company to take over your project, Be-cu can achieve your expectation.

Why Choose Be-cu 5 Axis CNC Machining

- Our 5 axis vertical machining center equipped with multiple position tool changers, there is no need for setup on different machinery, allows 5 axis machining of complex parts with high efficiency, saving time and cost.

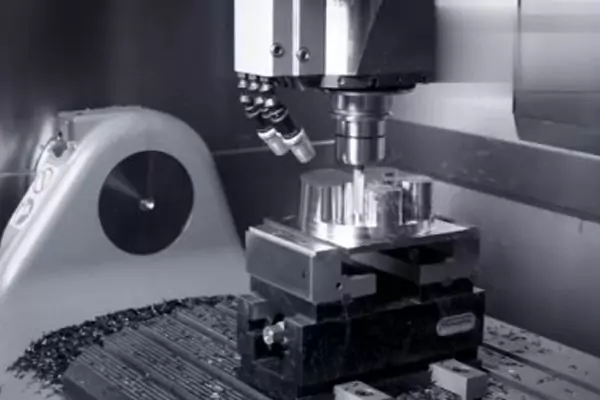

- We have 5 axis processing machine, vertical machining center, horizontal milling machine, lathe, line discharge and other specialized in metal cutting equipment. With the hands of skilled technicians, high precision can be achieved even in the machining and fine machining of complex shapes. The finished products are measured with high precision by 3d instruments to ensure the quality of the products.

- A complete process and quality control system in place to assess quality at every stage of our preparation, manufacturing, and inspection, to ensure the quality of 5 axis CNC machining components consistently meet the requirements.

- A series of secondary machining and finishing services are offered for further manufacturing, including 3/4 axis machining & milling, painting, sandblasting, anodizing, passivation, chrome plating, nickel plating, and more.

- Custom 5 axis milling parts with competitive prices, fast turnaround, improved productivity, and on-time delivery.

Simultaneous True 5-Axis High Speed Cnc Machining

The simultaneous true five-axis has the RTCP function. Automatic conversion can be performed according to the pendulum length of the spindle and the mechanical coordinates of the rotary table. The real five-axis with RTCP function only needs to set a coordinate system, and only needs to set the coordinates of the tool once.Simultaneous 5-axis CNC can be very fast, since there are no breaks between passes of the cutting tool.

3+2-Axis Machining

For 3+2 double turntable machining, it is necessary to set multiple coordinates to achieve the purpose of indexing processing. This form of 5-axis machining can be slower than simultaneous 5-axis CNC, but may result in more rigid parts and longer tool life.

Our 5 Axis Machining Material – The Advantage Of 5 Axis Cnc Machining

We offer 5 Axis Machining service for any types of custom 5 Axis Machining parts, whatever plastics or metals, simple or complex. Aluminum, titanium,copper,brass , stainless steel, resin and more, according to the characteristics and shape of the material to determine the most appropriate cnc machining method. From the cnc machining of small parts with complex and precise shape to the cnc machining of large parts, he is also good at 5 axis cnc machining materials with high difficulty and high precision.

Aluminum is one of the most machined lightweight metals today.Aluminum is highly machinable and relatively affordable, and the different types of aluminum alloys are applicable in a myriad of machining applications. However, in parts manufacturing, the process is more common with the use of aluminum, i.e., aluminum 5 axis machining.

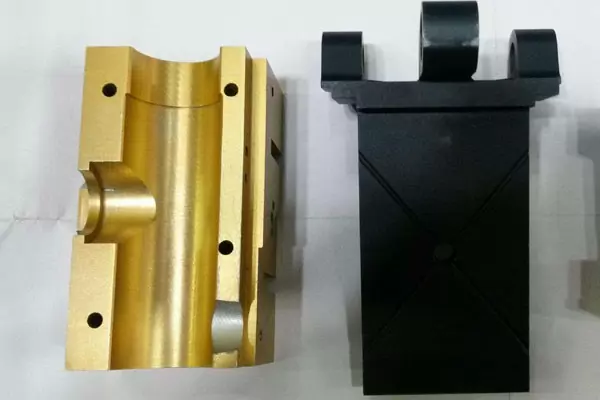

5 Axis Machining Copper

One of the significant benefits of using copper in 5 Axis machining is the demanding strength that makes it out of the box among other metal alloys. Many copper alloys have a strength of more than 200,000psi.Thus, the availability of substantial strength makes copper withstand high temperatures during machining.

Titanium is a chemical element with symbol Ti and atomic number 22. It is a lustrous transition metal with a silver color, low density, and high strength. Titanium is resistant to corrosion in sea water, aqua regia, and chlorine.Be-cu is a complete cnc machine shop capable of machining parts to customer specification (conventional and 5 axis machining).

Stainless steel is highly resistant to corrosion and rust, making it suitable for situations where a part may be exposed to the elements for a long period of time. Stainless steel is also fairly malleable and ductile.Be-cu is specialized in achieving extreme tight tolerance in 5 Axis CNC machining stainless steel products and parts manufacturing.

On 5 Axis cnc machine tools, brass cuts with ease on long production runs at the maximum permissible speeds with minimal tool wear, steady surface finish, and excellent chip control. Brass offers you real opportunities for fast, productive, cost-effective machining – in many cases, far more than you’ll achieve with steel or stainless steel, for instance.

5 Axis Machining Steel

At Be-cu, we have extensive knowledge and expertise in 5 Axis Machining, and years of machining experience have led us to have full confidence in CNC steel.Manufacturing of all parts will be done on our 5 Axis Machine. With a selection anchored by Mazak and DMG 5 Axis machines,we can produce complex assemblies and simpler parts.

5 Axis Machining Plastic

Every 5 axis machine of our machine assortment has stable mechanics which allows not only to mill any plastic but also high precision. Our customers produce parts for aerospace,optics and the automotive as well as instruments and lighted.With our machines, you can mill all kinds of plexiglass and polycarbonate to a thickness of about 30mm.

More Material

The wide variety of machining technology options in the Be-cu machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material. Behind it all is a staff of engineers and machining experts with a 30+ year track record of adapting to both new alloys and tried-and-true materials.

- Maintain the best cutting condition of the tool and improve the cutting conditions

- Effectively avoid tool interference

- Improve cnc machining quality and efficiency

- Shorten the production process chain and simplify production management

- Shorten the new product development cycle

- Complex shapes can be machined or processed,Reduce the number of clamping, and complete five-sided cnc machining in one clamping.

- Money and time-efficient with lesser preparation needed for fixtures.

Higher precision as the work-piece needs not to be moved to different work areas. - Brief lead times with boosted output along with cash flow.

- Capability to make use of higher speed for cutting with shorter tools and lower tool vibration.

- This is because the head can be lowered, and the cutter can be oriented properly

- A premium finish to the surface and good part quality.

- Improved efficiency and no operator error.

- No casting or running prototypes.

- Constant chip load and accurate cutting point.

- The longevity of the tools. and Accuracy in drilling holes

Currently, our 5 axis machining parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom 5 axis cnc machining service provides durable and affordable parts that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us for Rapid Quote or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your 5 axis machining project.

5 Axis Machining Applications – What is 5 Axis Machining Used for

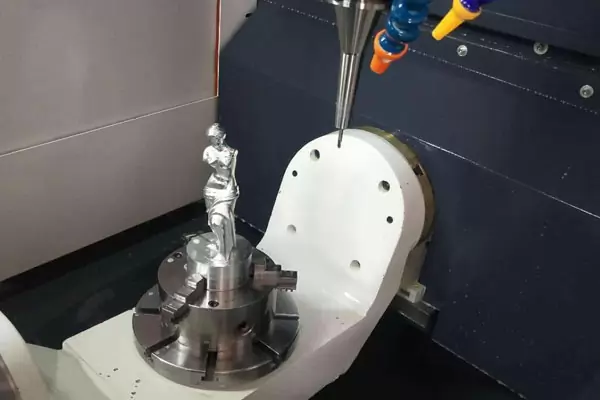

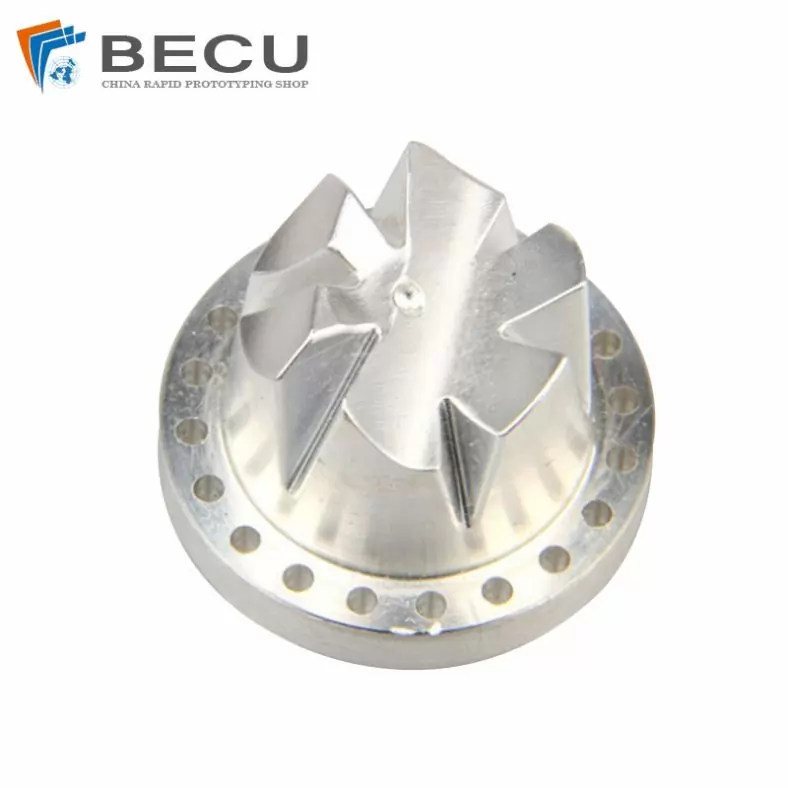

Because the 5 Axis Machining allows a very high precision without altering the structure of the material with a good rate of manufacture, 5 Axis Machining is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our 5 Axis Machining service is used to produce a variety of custom-designed 5 Axis Machining parts (as 5 axis impeller machining,5 axis aerospace machining etc.,)and products in all areas of the industry:

What Is 5 Axis Machining?-5 Axis Machining Define

On the 5 axis machining center, the tool can move across the X, Y and Z linear axes as well as rotates on the A and B axes, which makes the cutter can approach the workpiece from any direction and any angle. 5 axis machining is different from 5-sided machining. Therefore, 5 axis CNC machining services allow infinite possibilities of the machined parts. Hook surface machining, unusual shape machining, hollow machining, punching, oblique cutting, and more special processes can be done with 5 axis CNC service.Usually five-axis linkage refers to the linear interpolation movement of any 5 coordinates in x, y, z, A, B, and C.

Benefits of 5 Axis Machining

- The 5 axis machining parts can be finished on a single 5 axis machine, which reduces fixture and setup preparation, saves a lot of time

- Complex geometries can be processed with ease, high productivity and efficiency can be guaranteed at the same time

- Excellent surface finishes can be achieved, improves the overall quality of 5 axis CNC parts

- Expanded capabilities, higher accuracy, boosted throughput, and shortened lead time

- Improved cutting conditions, maintain the optimal cutting, and reduce damage to the tool

The Case Studies Of 5 Axis Machining Parts

You have a complex part design, Our 5 Axis Machining service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

5 Axis Cnc Machining Titanium Motorcycle Frame

-

5-axis Machining Aluminum 7075 Complex Special-Shaped Parts

-

5 Axis CNC Milling Aluminum 6061 Led High Bay Lighting Parts

-

5 Axis CNC Milling Aluminum Automotive Motor Enclosure

-

5-axis Machining Aluminum Alloy Motorcycle Gasoline Tank Housing

-

5 Axis Milling Machining Car Tail Light Housing

-

5 Axis Machining Automation Equipment Precision Parts

-

DMU Five-Axis Cnc Machining Aluminum Alloy Complex Structures Parts

-

Precision 5 Axis Machining Aluminum 6061 Aerospace Parts

-

Vertical 5 Axis Machining Complex Stainless Steel Parts

-

DMU 5-Axis Simultaneous CNC Machining Aluminum 7075 IPC Enclosure

-

CNC 5-Axis Precision Machining Aluminum Alloy Robot Parts

-

Aluminum 6063 Complex Robotic Parts By 5 Axis Cnc Machining

-

Turn-Mill Cnc Machining Stainless Steel 303 Parts

-

5 Axis Machining Optical Communication Parts And Telecom Parts