Titanium 5 Axis cnc machining Services – China Titanium 5 Axis CNC Machining Manufacturer

The chemical symbol of titanium, Ti, is considered to be a rare metal, a silvery white transition metal, characterized by light weight, high strength and metallic luster. Titanium has stable chemical properties, good corrosion resistance (including sea water, aqua regia and chlorine, and titanium will not be corroded when it is placed on the seabed for 20 to 50 years), good high temperature resistance, low temperature resistance, strong acid resistance, strong alkali resistance, high strength, low density and other excellent characteristics.

Titanium is comparable to steel in strength but is much less dense. This makes it a perfect material for jobs that require great strength but are limited by the weight of the part.

Titanium also differs from steel in its corrosion resistance, which is why it has many applications on ships and submarines. Titanium also boasts a great resistance to temperature, both high and lows. This and its lightweight characteristics make it the perfect metal for the aerospace industry to anything from recreational planes, to ballistic missiles.

Be-cu.com is an ISO 9001:2015 certified CNC machine shop specializing in the manufacturing of 5 axis CNC machined titanium parts for various industries and the fabrication of multifaceted upper-level products for challenging projects. Backed by superior in-house equipment and tool facilities, highly skilled machinists, and enormous experience, we can deliver a wide variety of custom titanium alloy components and 5 axis cnc parts with the highest quality and exactly matched specifications that help optimize client supply chains.

Custom Titanium 5 Axis machining parts are inspected thoroughly at each stage of production for each detail and accuracy, enabling our customers to be confident in the quality control process. Even though any problems during the process, we’ll keep running the job and make adjustments until all the issues are addressed.

Titanium Alloy Grades We 5 Axis CNC Machining With

Titanium Alloy Grade 1 is the first of four commercially pure titanium grades with great impact and corrosion tolerance, and excellent weldability, which possesses the highest softness and ductility of these titanium alloy grades.

Titanium Grade 2 is a pure alpha titanium with higher strength than Grade 1 and equally performs great bio-compatibility and corrosion resistance. Therefore, this type of titanium alloy is widely used in all product forms for industrial services.

Titanium Grade 5 offers higher strength and temperature tolerance as compared to that offered by Grade 2. That is the reason why this kind of titanium alloy is well known for its great properties and is most commonly used in vast applications.

Why Choose Our Titanium 5 Axis Machining Service?

- Save time and money for your titanium project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of titanium grades and alloy materials can be 5 axis machined

- Custom complex titanium machined parts and components at specific tolerances

- High speed 5 Axis Machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Titanium 5 Axis Machining Case Studies

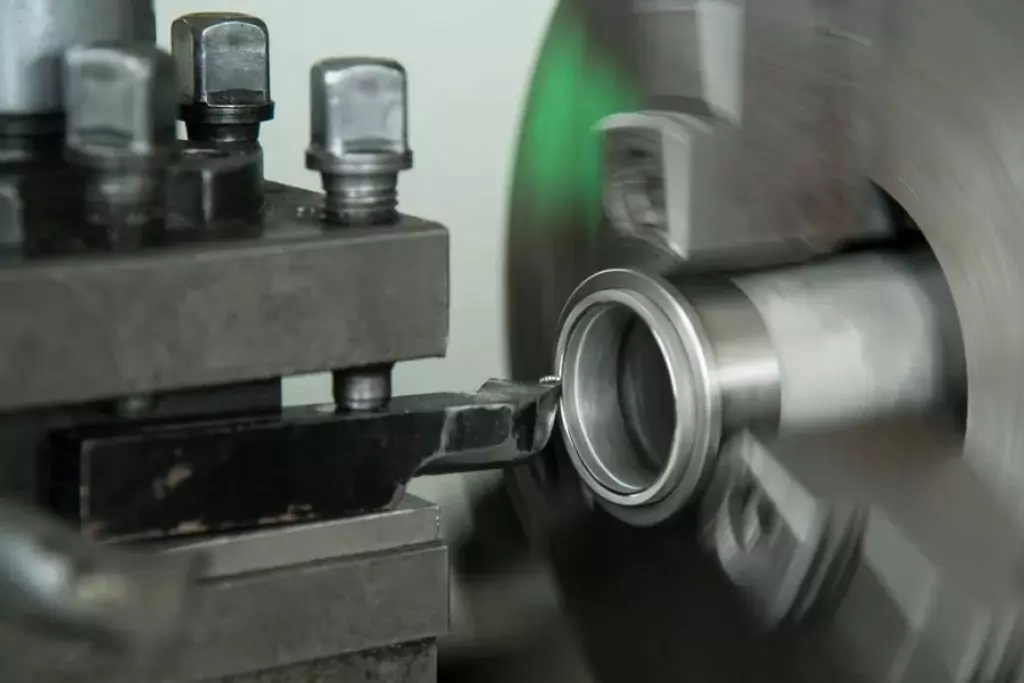

5 Axis Machining processes such as precision 5 Axis Machining and mazak turn-mill machining are today considered the most economic way to make titanium prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making titanium concept models and precise functional components. Understanding the properties of different titanium alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on titanium alloy. Be-cu prototyping company provides a range of solutions for the 5 Axis machining of titanium parts.