Brass is an alloy of copper and zinc. Brass consisting of copper and zinc is called ordinary brass. If it is a variety of alloys composed of more than two elements, it is called special brass. Such as copper alloy composed of lead, tin, manganese, nickel, iron and silicon. Brass has strong wear resistance. Special brass is also called special brass. It has high strength, high hardness and strong chemical corrosion resistance. The mechanical properties of cutting are also more outstanding than that of brass. Seamless copper tube drawn from brass is soft and has strong wear resistance. Brass seamless tubes can be used for heat exchangers and condensers, cryogenic pipelines, and submarine transport tubes. Manufacture sheet, bar, pipe, casting parts, etc. The copper content is 62%~68%, with strong plasticity. Pressure resistant equipment is manufactured.

Brass 5 Axis cnc machining Services – China Brass 5 Axis CNC Machining Manufacturer

5 Axis Milling Machining is the most common form of machining, a material removal process, which can create a variety of features and complex structure on a part by cutting away the unwanted material. The 5 Axis machining process requires a milling machine, workpiece, fixture, and cutter. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to a platform inside the milling machine. The cutter is a cutting tool with sharp teeth that is also secured in the milling machine and rotates at high speeds. By feeding the workpiece into the rotating cutter, material is cut away from this workpiece in the form of small chips to create the desired shape.Be-cu.com learned from many hardware startups that their teams were mainly made up by technical engineers and product developers, who lacked supply chain management experience as well as practical manufacturing knowledge.

Many hardware startups believed that with technology and R&D ability, they would never worry about not finding a market. More too often, they ignored the problems they might face in the production process.

Firstly, it is difficult to identify the best manufacturing solution. Secondly, it can be time-consuming to find the most suitable factory for their customized parts. They spent a lot of time on the phone or emails to make inquiries, send drawings, wait for feedback, but never got the best price and the most satisfactory delivery time. In addition, Be-cu.com has found out that customers couldn’t keep things going as planned at the product development stage due to the manufacturing issues, which always led to a delayed launching time for a new product. Last but not least, bad quality control of the factories that they turned to can be another horrible disaster for many startups companies.

Our skilled and knowledgeable staff deliver the most cost-effective 5 axis machining for your Brass Machined parts. We work tirelessly to improve not only our production of the product through innovations in our machining but also in our methods behind the scenes with our AS9100D & ISO 9001:2015 certification. Prints and other prudent information are safe with Be-cu.com as well. Being an ITAR registered company, we go above and beyond to protect any and all information exchanged, different from many other China manufacturers.

We have produced Brass 5 axis Machined parts for a growing list of industries including Aerospace, Medical, and Automotive industries..

It was with the vision to make manufacturing easier that the founders and pioneers of Be-cu.com started searching for ways to solve the all above problems.

Why Choose Our Brass 5 Axis Machining Service?

- Save time and money for your brass project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of brass grades and alloy materials can be 5 axis machined

- Custom complex Brass machined parts and components at specific tolerances

- High speed 5 Axis Machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

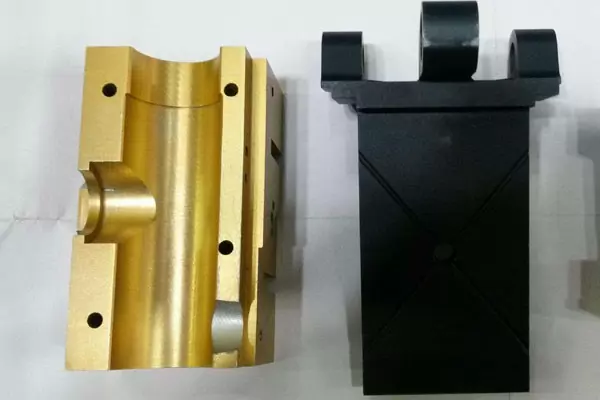

Top Brass 5 Axis Machining Case Studies

5 Axis Machining processes such as precision 5 Axis Machining and mazak turn-mill machining are today considered the most economic way to make Brass prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making Brass concept models and precise functional components. Understanding the properties of different Brass alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on Brass alloy. Be-cu prototyping company provides a range of solutions for the 5 Axis machining of Brass parts.