The Define Of Copper And Copper Alloy Cnc Milling

Most of the modern industrial civilization products use metal materials, especially important parts, which show their reliability, but there are very few cases of using a single metal, and most of them use alloy materials. The characteristics of copper and copper alloys are not only strength, but also excellent electrical and thermal conductivity.

It is necessary to give full play to their advantages of good electrical conductivity in order to contribute to the society to the greatest extent. In modern times, especially since the industrial revolution of the seventeenth century and the discovery of Faraday’s law of electromagnetic induction, copper and copper alloys have excellent electrical conductivity, thermal conductivity, corrosion resistance, easy machining, beautiful appearance and are widely used in modern engineering and technology fields. , widely used in machinery, electronics, electrical, chemical, transportation, energy, construction, information and communications and other fields, for example: a tractor uses an average of 31 kg of copper, a Jiefang car uses an average of 21 kg of copper, various household appliances, Industrial devices are inseparable from copper and copper alloy products, which are irreplaceable and important engineering materials in the national economy.

According to foreign statistics, the consumption ratio of copper and copper alloys to steel in developed countries is about 1.3:100. The variety and consumption of copper and copper alloys have become one of the indicators to measure a country’s industrial technology level.

The fundamental feature of copper and copper alloys widely used in the field of engineering and technology is that they are currently economical conductive materials. Pure copper has high electrical conductivity, thermal conductivity, suitable strength, excellent corrosion resistance, easy to brazing and deformation machining, and is widely used in the manufacture of various electrical wires and conductors.

The proportion of industrial applications accounts for more than half of the total output, for example: manufacturing 10,000 kilowatts of power generation equipment, including power transmission and transformation equipment, requires nearly 800 tons of copper. In recent years, with the increasing urgency of energy, energy saving and consumption reduction work in various industries has become increasingly prominent. Motors are widely used power consumers.All countries attach great importance to the development and promotion of high-efficiency and energy-saving motors.

An important way to reduce resistance consumption is to increase motor windings. cross-sectional area. At the same time, with the improvement of people’s living standards, the civil load continues to increase, and the cross-sectional area of various transmission cables is also increasing. It provides broad development prospects in the electrical field.

Another feature of copper and copper alloys is that they have excellent alloying properties, and can form alloys with their own characteristics with most of the current metal or non-metal elements. At present, more than 250 alloy grades have been formed, with nearly 10,000 specifications. The product series meets the needs of all walks of life, and most copper alloys have strong corrosion resistance.For example, white copper has excellent mechanical properties, machining properties and corrosion resistance, and is suitable for corrosion-resistant environments under high temperature and high pressure. Widely used in medical, instrumentation, shipbuilding, chemical industry and other fields; tin bronze has excellent elasticity and high mechanical properties, and is widely used in the manufacture of elastic components in various instruments and instruments and some bearing friction sleeves; aluminum bronze has excellent elasticity and high mechanical properties. Compared with steel, it has high strength and excellent corrosion resistance, and is widely used in the manufacture of various heavy-duty wear parts.

With the development of modern science and technology, especially with the rapid development of information technology, new types of alloys used in the field of high-tech are emerging, representing the development direction of contemporary engineering materials and having broad development prospects.

At the same time, copper and copper alloys are still the best environmental protection materials. The copper alloys used in various devices can be completely recovered and recycled. Recycled copper can maintain its original various superior properties, which is unmatched by other recycled materials. Given the relative shortage of copper resources in China, making full use of secondary copper resources has become an emerging industry. At present, with the increase in the output of electronic products and automobiles, the demand for copper processed products with excellent electrical and thermal conductivity is increasing. The requirements for straightness, surface roughness, gloss, and discoloration resistance are getting higher and higher.

Cnc Milling Copper Alloy – Copper CNC Milling Service In China

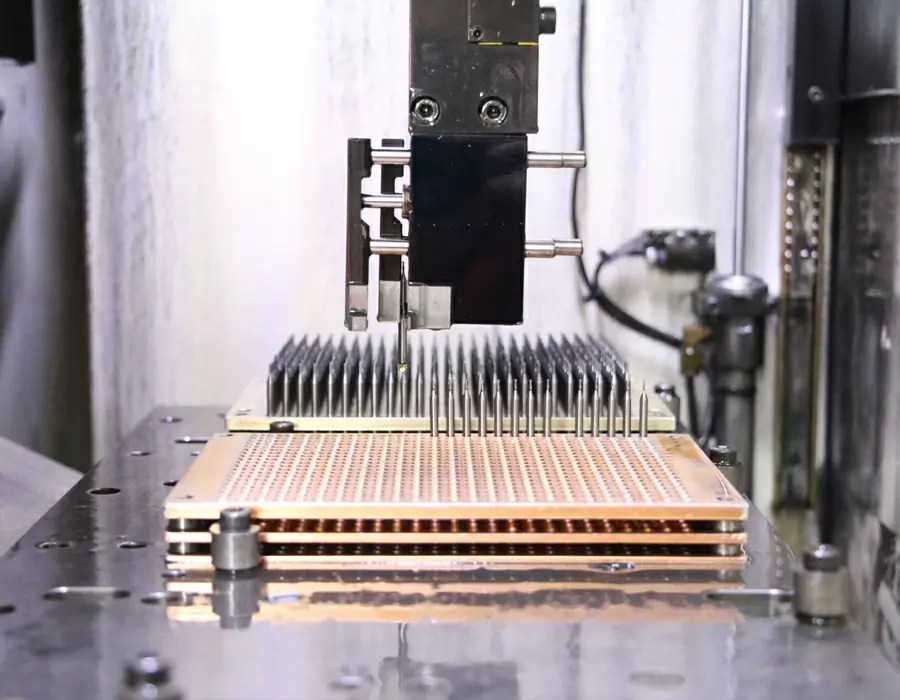

Copper machining parts manufactured using wire EDM and CNC milling technologies. There are vast copper parts on the market to meet varying requirements, because each type of spare parts or mold accessories is built differently, the main copper parts will be fabricated in different geometries. With years of experience in metal fabrication and Copper CNC milling, Be-cu.com is capable to produce premium quality custom machined copper parts in various specifications, according to the drawing or design of clients. Whether you want to seek copper spare parts for vast application, we offer a wide selection of hardware and tools made from copper and copper alloys, our CNC milling copper parts can last a long time and maintain stability for improving the parts quality. And each part will be made in exact dimensions to fit your project well.Whether the copper 3 axis milling/4 axis milling/5 axis milling parts are polished or treated with other finishing techniques, we’ll try our best to confirm its specification and function do not be influenced, countless inspection and check will be conducted before shipment. Let Be-cu(Pintejin Group) Copper CNC Milling service complete the next project for you.

The Our Guarantee Of Milling Quality

- – Premium quality, high consistency, and repeatability

- – Advice on design optimization and technical support

- – Outstanding service and delivery speed

- – Quality assurance and strict quality inspection

- – Tolerance : +/-0.005mm

- – Surface Treatment : Custom

- – Quality Control : Strictly Quality control in the whole process, from material to packing,Coordinate-measuring machine

- – Customized Drawings : Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted

The Advantage Of Cnc Milling Copper

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of copper machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient CNC machining factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Outstanding Copper Cnc Milling Machine List In Be-cu.com

- CNC Swiss Turn by Tsugami

- MAZAK 5 Axis Turn-Mill Machine

- CNC Swiss Turn by Tsugami

- High Speed Drilling-Tapping Machine

- DMU 5 Axis Cnc Machine

- CNC Mill Turn Centers—12 machines

- Multi Spindle Cam Automatics

- CNC Brother Production Milling

- Check Out BE-CU Equipment List

Our Case Studies Gallery Of CNC Milling Copper Parts

Pintejin Group(Be-cu.com) is a top CNC machining company and supplier provides customized copper milling components, accessories & products.Based on the experiences in machining copper alloys, we are capable to give you effective solutions from design review, quotation to production fast.We are also capable of precision cnc milling other metals if you required them.

-

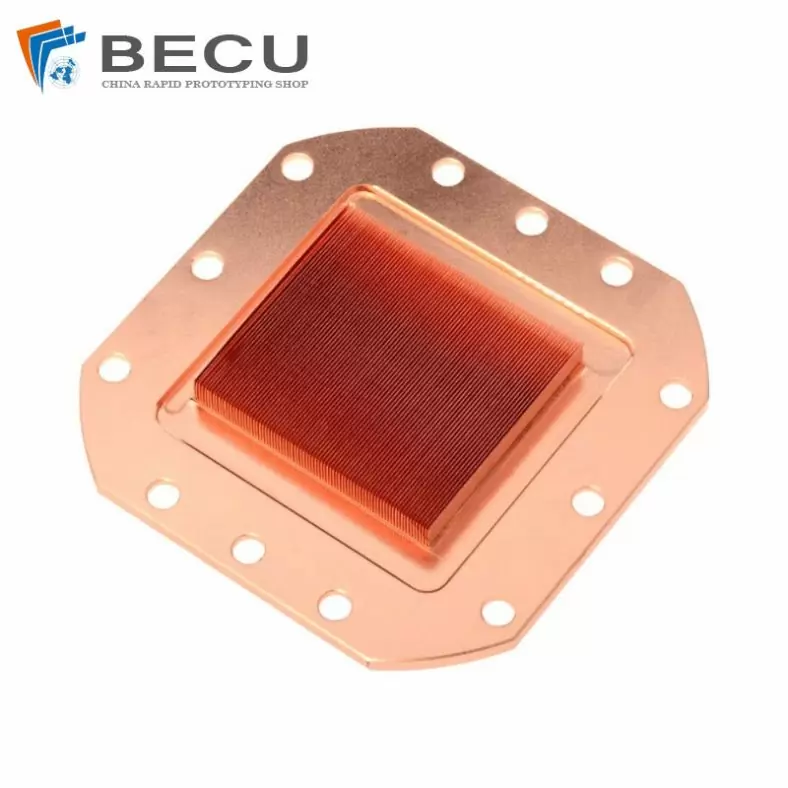

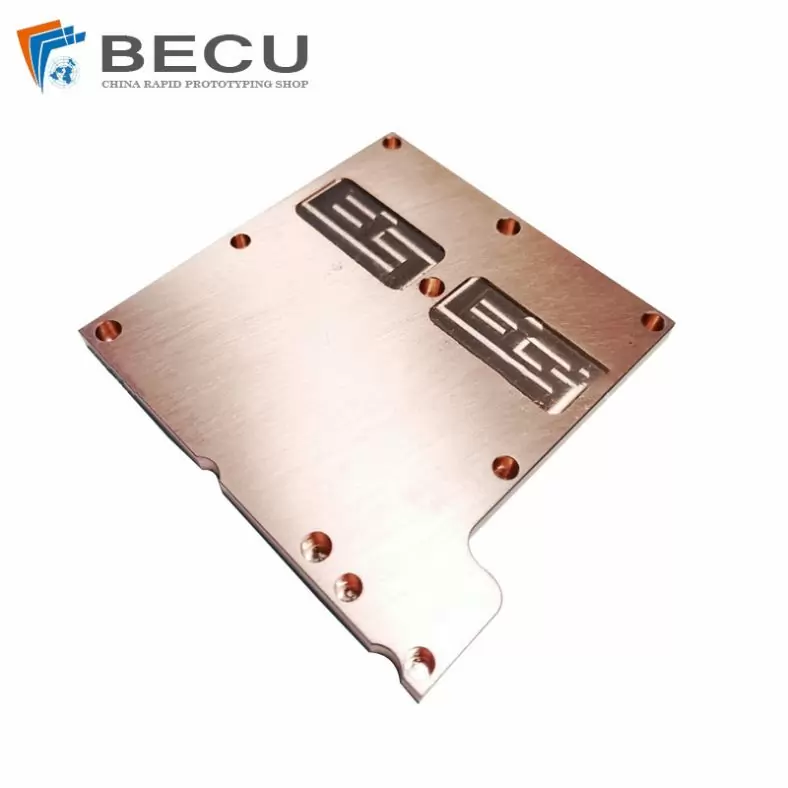

Custom Machining Copper Water Cooling Heat Sink

-

Cnc Carved Machining And Wire Cutting Copper Electrode

-

CNC Milling Automotive Audio Amplifier Base

-

Precision Machining Heatsink Spacer Substrate

-

Precision Milling Machining Chrome-Plated Copper Spare Parts

-

CNC Machining T2 Copper Conductive Electrode Connector

-

CNC Machining Electrical Conduction Copper Bar With Electro-Galvanized