The Define Of Titanium And Titanium Alloy Cnc Milling

Titanium is a new type of metal. The performance of titanium is related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purest titanium iodide has an impurity content of no more than %, but its strength is low and its plasticity is high. The properties of % industrial pure titanium are: density ρ=cm3, melting point 1800℃, thermal conductivity λ=, tensile strength σb=539MPa, elongation δ=25%, section shrinkage ψ=25%, elastic modulus E =×105MPa, hardness HB195.

Titanium is an allotrope with a melting point of 1720 °C. When it is lower than 882 °C, it has a close-packed hexagonal lattice structure, which is called α titanium; when it is above 882 °C, it has a body-centered cubic lattice structure, which is called β titanium. Using the different characteristics of the above two structures of titanium, appropriate alloying elements are added to gradually change the phase transformation temperature and phase content to obtain titanium alloys with different structures.

- High specific strength: The density of titanium alloys is generally around cm3, which is only 60% of that of steel. The strength of pure titanium is close to that of ordinary steel, and some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much higher than that of other metal structural materials, see Table 7-1, and parts and components with high unit strength, good rigidity and light weight can be produced. At present, titanium alloys are used in aircraft engine components, skeletons, skins, fasteners and landing gear.

- High thermal strength: for α titanium alloy, the σb of TA6 reaches 422MPa at 350°C, the σb of TA7 reaches 491MPa, and the σb of TA8 reaches 687MPa at 500°C; for α+β titanium alloy, at 400°C, TC4 The σb of TC10 reaches 618MPa, the σb of TC10 reaches 834 MPa, the σb of TC6 and TC7 reaches 589MPa at 450℃, the σb of TC8 reaches 706MPa, and the σb of TC9 reaches 785MPa at 500℃. These two types of titanium alloys still have high specific strength in the range of 150 ℃ ~ 500 ℃, while the specific strength of aluminum alloys decreases significantly at 150 ℃. The working temperature of titanium alloy can reach 500 ℃, and the working temperature of aluminum alloy is below 200 ℃.

- Good corrosion resistance: Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than that of stainless steel; its resistance to pitting corrosion, acid corrosion and stress corrosion is particularly strong; it is resistant to alkali, chloride, Chlorine organic substances, nitric acid, sulfuric acid, etc. have excellent corrosion resistance. However, titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.

- Good low temperature performance: titanium alloy can still maintain its mechanical properties at low temperature and ultra-low temperature. At -100°C and -196°C, the σb of TA4 is 893MPa and 1207MPa, respectively, at -196°C and -253°C, the σb of TA7 is 1216MPa and 1543MPa, respectively, the σb of TC1 is 1133MPa and 1354MPa, and the σb of TC4 is 1511MPa and 1785MPa. Therefore, titanium alloy is also an important low-temperature structural material.

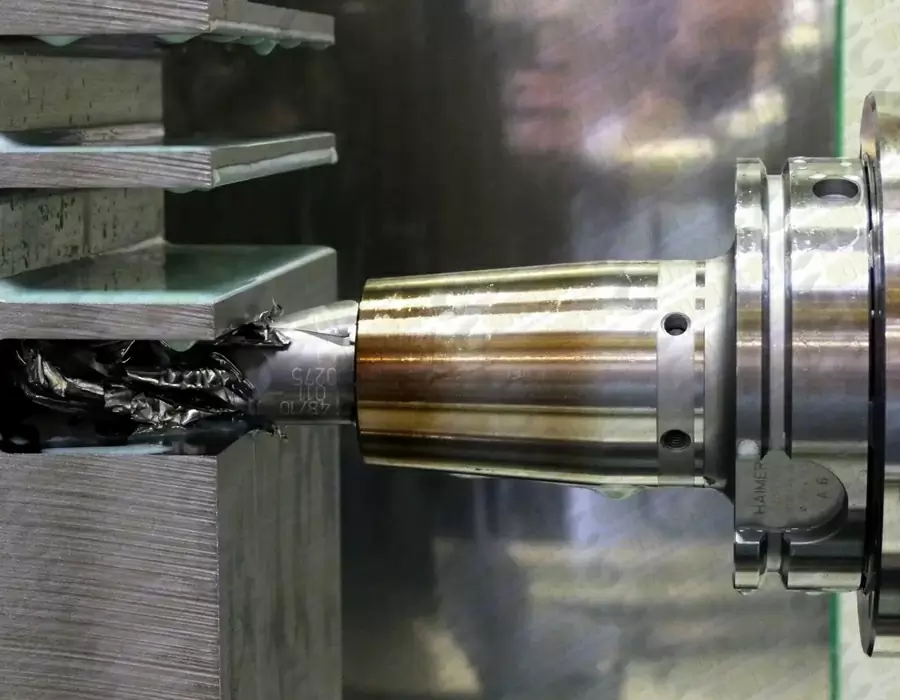

- High chemical activity: Titanium has high chemical activity and produces strong chemical reactions with O, N, H, CO, CO2, water vapor, ammonia, etc. in the atmosphere. When the carbon content is greater than %, hard TiC will be formed in the titanium alloy; when the temperature is high, a hard surface layer of TiN will also be formed when it interacts with N; when the temperature is above 600 °C, titanium absorbs oxygen to form a hardened layer with high hardness; An embrittlement layer is also formed when the hydrogen content increases. The depth of the hard and brittle surface layer produced by absorbing gas can reach ~ mm, and the degree of hardening is 20% to 30%. The chemical affinity of titanium is also large, and it is easy to adhere to the friction surface.

- Small thermal conductivity and small elastic modulus: the thermal conductivity of titanium is λ=/, which is about 1/4 of nickel, 1/5 of iron, and 1/14 of aluminum, and the thermal conductivity of various titanium alloys is higher than that of titanium. The thermal conductivity decreased by about 50%. The elastic modulus of titanium alloy is about 1/2 of that of steel, so its rigidity is poor and it is easy to deform. It is not suitable to make slender rods and thin-walled parts. times, resulting in severe friction, adhesion and bond wear on the flank of the tool.

Cnc Milling Titanium Alloy – Titanium CNC Milling Service

OEM CNC milling titanium alloy spare parts produced by Be-cu.com, we also offer custom CNC milled aluminum parts for various different industries. In our titanium CNC machining shop, 3 axis cnc milling, 4 axis cnc milling, 5 axis cnc milling and more processes are available, as well as excellent surface finishing.Our Milling Titanium Alloy Grades: grade 5 (Ti 6Al-4V), grade 2, grade 7, grade 23 (Ti 6Al-4V Eli), etc.Titanium milling&turn-mill machining services at Be-cu.com are specialized in precision milled parts, deliver premium quality and high security.BE-CU rapid CNC milling services support the quick turnaround and short lead time of our precision titanium products.If you are looking for a reliable titanium milling services supplier, welcome to send your inquiry to us, Be-cu.com can manufacture extensively custom titanium parts to achieve your demands.

Our Guarantee Of Milling Quality

- – Premium quality, high consistency, and repeatability

- – Advice on design optimization and technical support

- – Outstanding service and delivery speed

- – Quality assurance and strict quality inspection

- – Tolerance : +/-0.005mm

- – Surface Treatment : Custom

- – Quality Control : Strictly Quality control in the whole process, from material to packing,Coordinate-measuring machine

- – Customized Drawings : Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted

Advantage Of Milling Titanium

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of titanium machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient CNC machining factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Outstanding Titanium Cnc Milling Machine List In Be-cu.com

- CNC Swiss Turn by Tsugami

- MAZAK 5 Axis Turn-Mill Machine

- CNC Swiss Turn by Tsugami

- High Speed Drilling-Tapping Machine

- DMU 5 Axis Cnc Machine

- CNC Mill Turn Centers—12 machines

- Multi Spindle Cam Automatics

- CNC Brother Production Milling

- Check Out BE-CU Equipment List

Our Case Studies Gallery Of CNC Milling Titanium Parts

Pintejin Group(Be-cu.com) is a top CNC machining company and supplier provides customized Titanium milling components, accessories & products.Based on the experiences in machining Titanium alloys, we are capable to give you effective solutions from design review, quotation to production fast.We are also capable of precision cnc milling other metals if you required them.