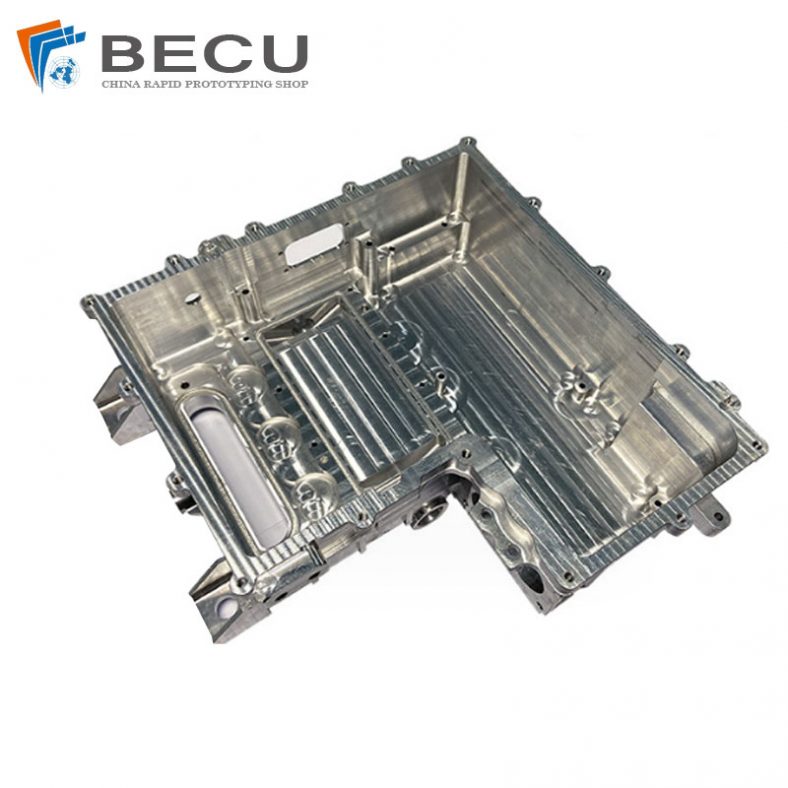

IOT Robotic Parts

- Product Name: Aluminum Robots Parts

- No+Color:Custom

- Surface Treatment:Oxidation

- Product Material: Aluminum Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Robots Parts

- Production Process:Cnc Machining

- Size: According To Customer’s Drawings

High-Quality Five-Axis Precision Cnc Milling Machining IOT Robotic Parts

ISO 9001:2015 certified. Five-Axis Precision Cnc Milling Machining services for IOT Robotic Parts industries. Processes include milling, turning, broaching, counterboring, drilling, grinding, honing, knurling, lapping, sawing and threading. Additional services such as heat treating and finishing are provided. Prototype and low to high volume production offered.

The Advantages Of Five-Axis Precision Cnc Milling Machining IOT Robotic Parts

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Five-Axis Precision Cnc Milling Machining IOT Robotic Parts

| Material | Aluminum 6063 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Automotive,Motorcycle |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU 5 Axis cnc machining Company

As an experienced and professional machine shop specialized in CNC manufacturing for many years, BE-CU.COM is capable of precision 5 axis CNC machining services and 5 axis milling. Whether you are in need of high-quality and precise metal or plastic components, we can provide 5 axis machining parts to worldwide clients for a variety of industries including automotive, medical, military, aerospace, mechanical, machine tool, high-tech, and more, with excellent machining and programming skills, as well as 5 axis CNC machining center. No matter how complex the CNC machining parts, each step will be executed with a rigorous attitude, to deliver exceptional 5 axis machining components that demonstrate the highest quality standards. Even though any problems during the process, we’ll keep running the job and make adjustments until all the issues are addressed.If you require a well-established and cost-effective CNC machining company to take over your project, BE-CU can achieve your expectation.

-

5 Axis CNC Machining Medical Olecranon Plate

-

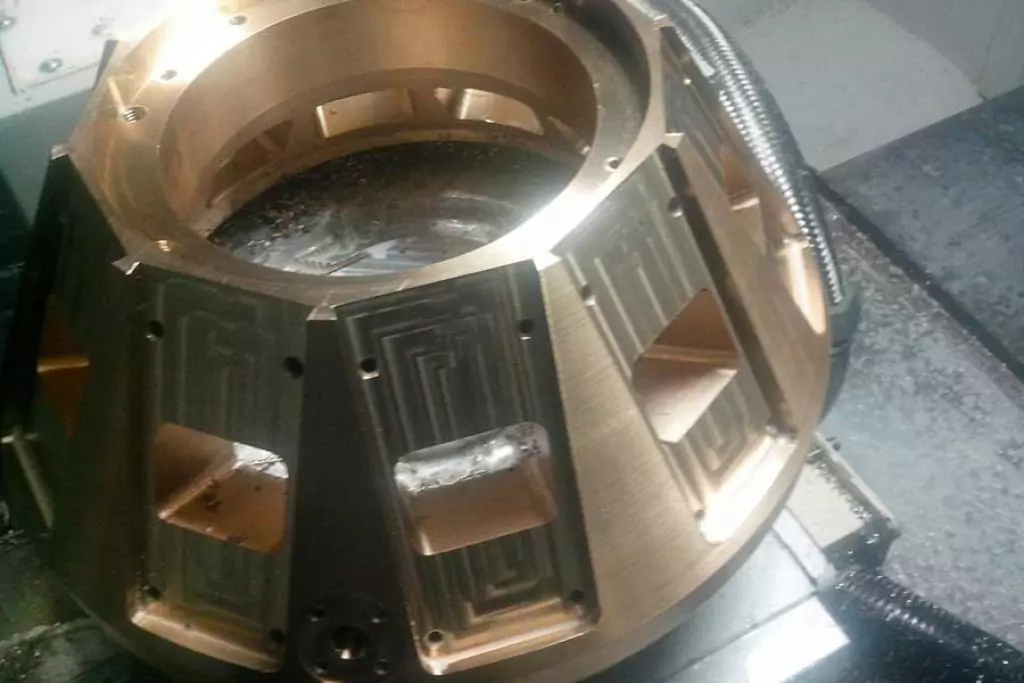

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

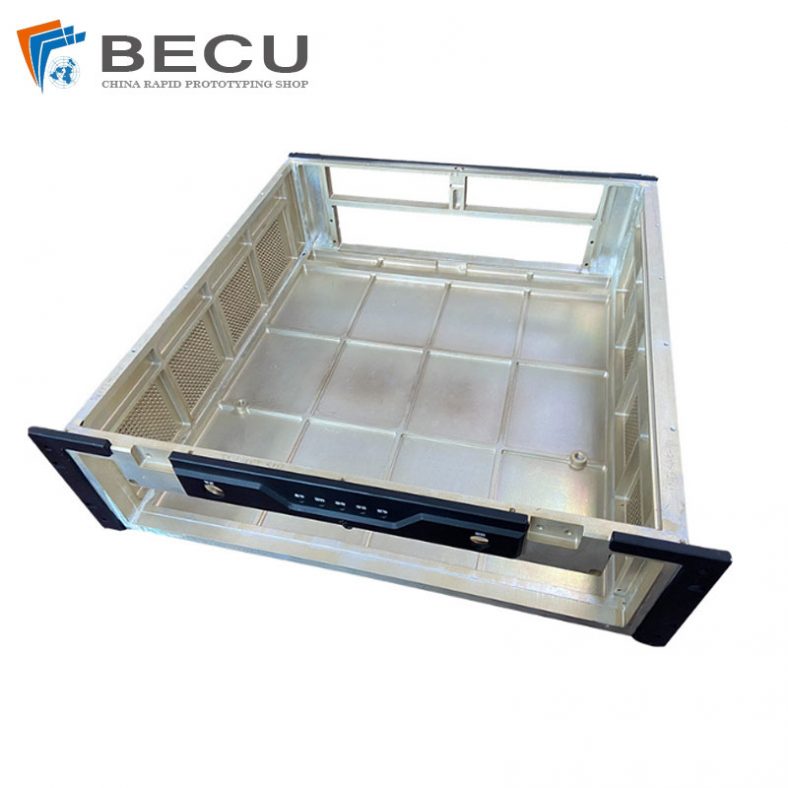

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

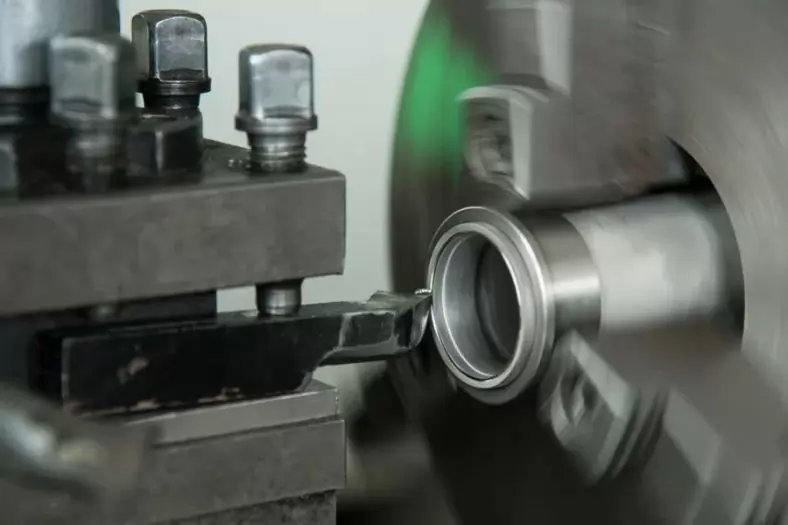

CNC 6063 Aluminum Automotive Motor End Cover

-

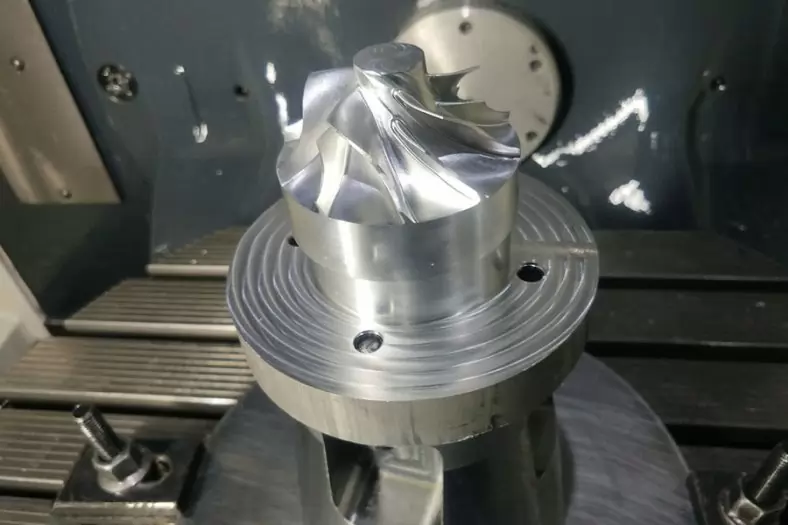

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining