Swiss Machining

- Proprietary 100% automated inspection available

- Boost production efficiency and cut unit costs

- parts with an unusually long and slender profile

- up to 12 axes of CNC control

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

Online Swiss Turning Services

Want to shorten production cycle and reduce cost of your machinery components? Whether you are in need of high-quality and precise metal or plastic components, we can provide 5 axis machining parts to worldwide clients for a variety of industries including automotive, medical, military, aerospace, mechanical, machine tool, high-tech, and more, with excellent machining and programming skills, as well as swiss machines.Send your CAD files or inquiry to us, a fast, free online CNC quote of required swiss machining components will be back. Get your CNC Swiss Turning Parts into processing in the shortest time.

Swiss Machining Services – Screw Machining Companies With Swiss Cnc Machines

Be-cu is a China top swiss machining company, CNC Swiss screw machining & machined products are a specialty of Be-cu.,and have the capability to provide Swiss CNC machining services with the latest Swiss turning and machining technology for the manufacturing needs of various industries all over the world. Based on years of experience, advanced manufacturing equipment, accomplished engineers and technicians, and cutting-edge prototyping facilities, we are able to bring your concept or idea to the market in a cost and time-saving way, This commitment to timely delivery, consistent quality and minimized cost is backed by an extensive selection of Swiss equipment on the Be-cu CNC equipment list.Our expertise with these machines allows us to make the part and do the micro drilling on one machine, reducing the handling on these parts. We manufacture a wide variety of precision parts in quantity on these machines.We make specialty nozzles for several industries; the medical industry, machinery and hi tech;Swiss Machining Connector Components. We also make several type of valves, carburetors, orifice plates, and other parts for the automotive, telecom, and aerospace industries.Welcome to contact us to get a free quote fast.

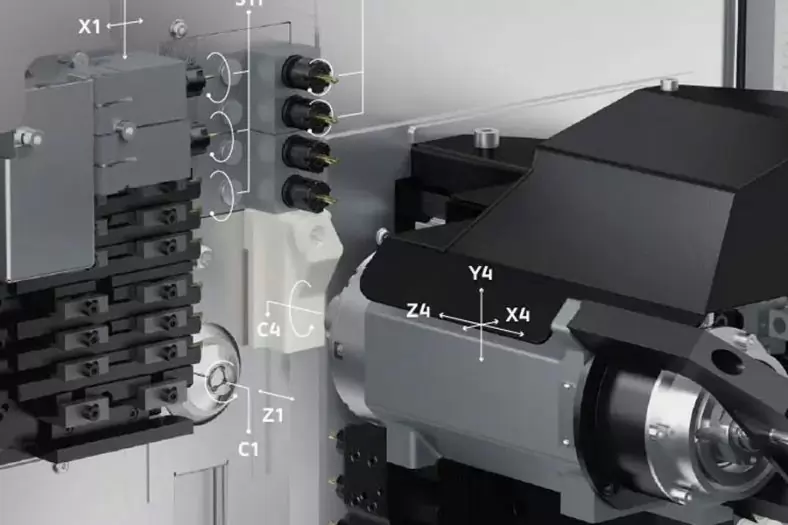

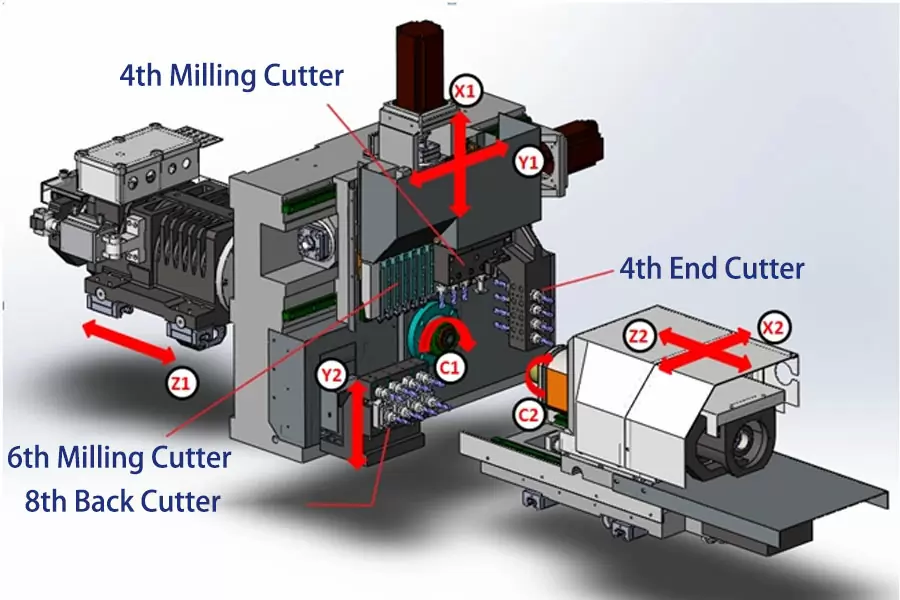

7 Axes Swiss Screw Machining

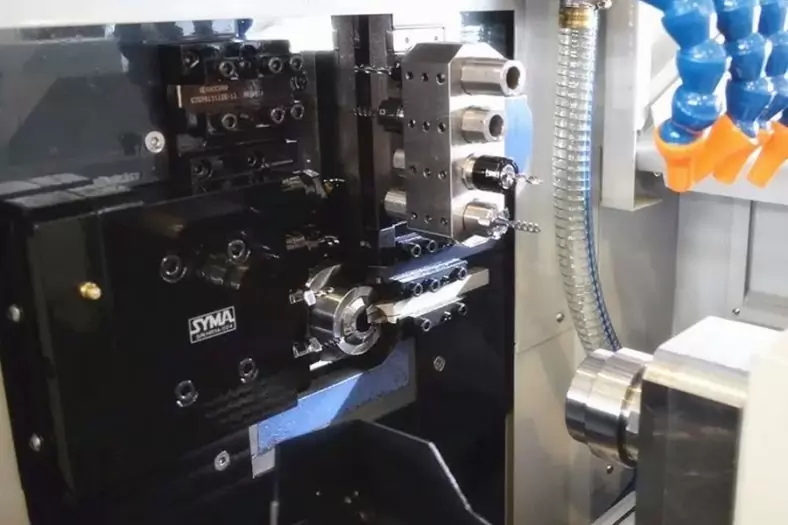

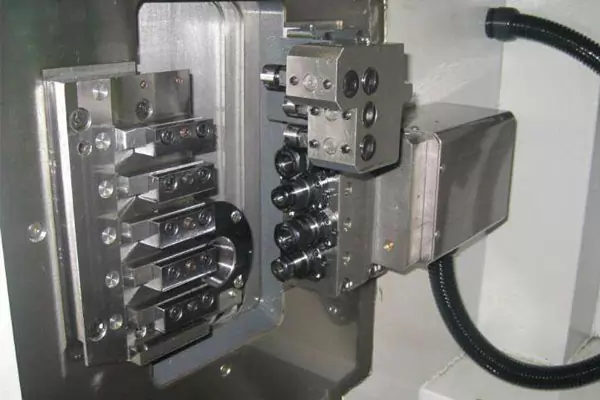

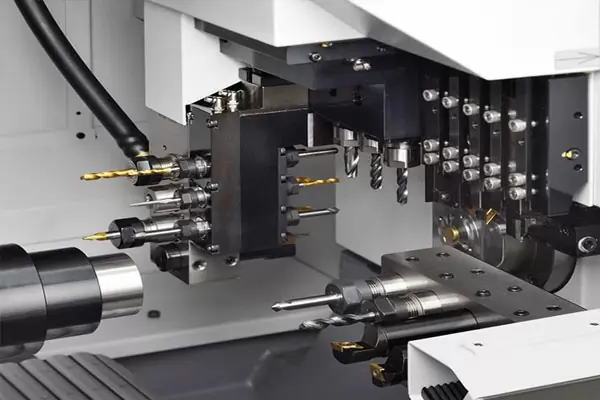

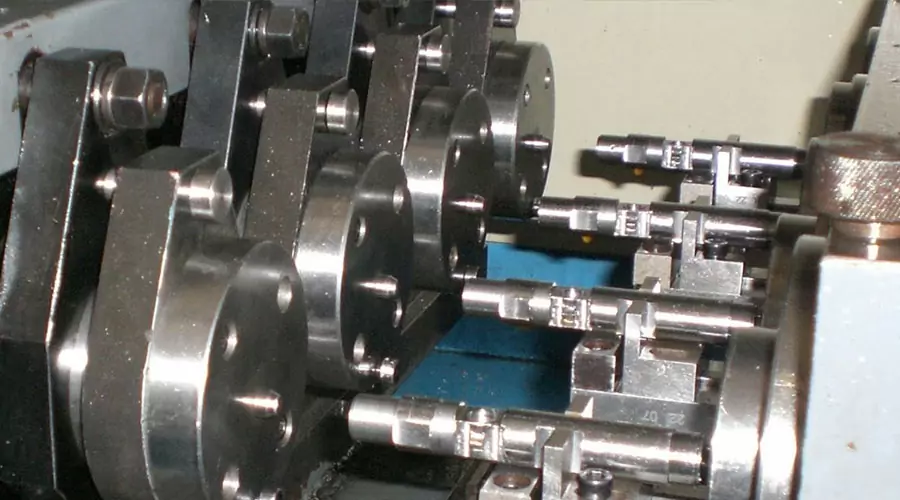

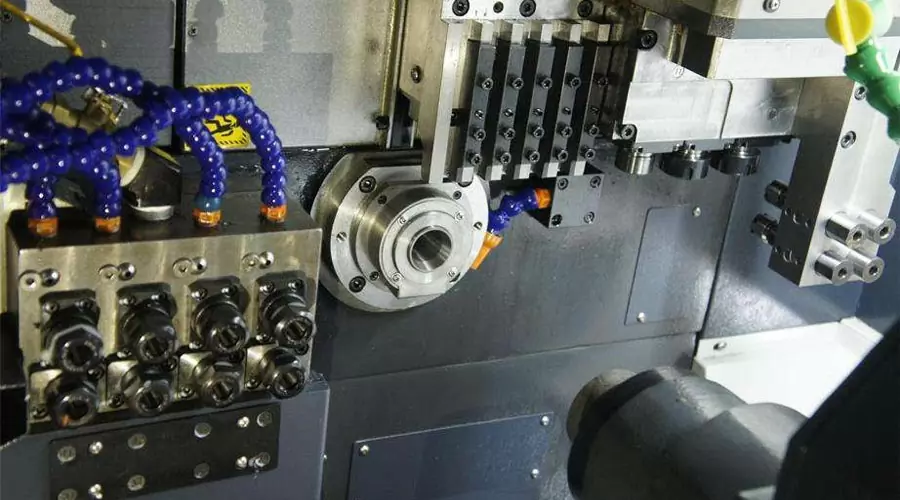

TCNZ-26D-32D dual-spindle Swiss Machine, dual-spindle simultaneous machining, with X1, Y1, Z1, X2, C1, five axes, (optional Y2) a total of 7 axes. It can perform external turning, groove turning, thread turning, axial drilling, tapping, boring, reaming, radial multi-drilling, tapping, flat milling, slot milling, and other cnc machining procedures on the workpiece.

The end face power head and deep hole drilling function can complete large-scale precision machining of steel parts, stainless steel parts, etc. to achieve high-speed cutting of difficult parts, and are widely used in electronics, communications, office and other industries. Especially suitable for slender multi-process shaft parts machining , such as valve core, bone nail, airbrush and other products.

Be-cu Swiss Machining Services Capabilities

As one of the fastest-growing precision Swiss Machining services China suppliers, the following swiss screw machining capabilities at Be-cu are available to serve your needs of swiss turned parts, from rapid prototyping to precision parts, to end-use production.

Our attention to detail allows us to produce parts that are extremely precise, consistent, and to specification. Parts where flow is critical are our specialty on our swiss style lathes.

- Our lean manufacturing facility with the latest CNC technology allows us to produce your components efficiently, therefore, we are able to quote competitively.

- Custom CNC Swiss turning and machining parts can be produced fast and efficiently, suitable for a high volume production run of small parts.

- Precision Swiss CNC machining candle your complex parts project, tight tolerance, and high accuracy can be achieved.

- Reduced secondary machining due to the application of live tooling and sub-spindles, accelerate the whole process.

- Be-cu is committed to providing defect free products and services that comply with all aspects of our customer requirements, and strict inspection throughout the whole machining process, as well as quality tests for the product.

Swiss Machining Metals

- Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

- Alloy: brass 360, 101 copper, 110 copper, 932 bronze, zinc, etc.

- Titanium: grade 2, grade 5, etc.

- Stainless steel: 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, etc.

- Steel: 4140, 4130, A36, 1018, etc.

Swiss Machining Plastics

- Plastic: POM (Delrin), ABS (Acrylonitrile Butadiene Styrene), HDPE, Nylon, PLA, PC (Polycarbonate), PEEK (Polyether Ether Ketone), PMMA (Polymethyl Methacrylate or Acrylic), PP (Polypropylene), PTFE (Polytetrafluoroethylene), etc.

- Other CNC Turning materials: Graphite, VeroClear

Other Swiss Machining Capabilities

Driven by the idea of continuously perfecting turning, alongside swiss machining service Be-cu also offers you accessorial solutions that enable you to further optimise the production of your components using various methods, such as with Threading.

Drilling

We use various types of CNC drilling machines including upright, bench, radial, which allows us to drill holes of both simple and complex patterns up to 7 cm in diameter.

Boring

The powerful equipment CNC control and the rotary table for multi-sided machining of workpieces in one clamping offer solutions for a wider range of milling and drilling work.

Threading

Thread cutting helps to create screwed connections on parts. Be-cu provides best thread turning services for the fabrication of both small and large series of parts of any complexity.

Knurling

Be-cu is an experienced knurling services supplier,Knurling is a process that creates a rough-textured pattern on ductile metals, usually for the purpose of enhancing grip and appearance.

Swiss Machining Applications – What is Swiss Machining Used for

Because the swiss screw machining allows a very high precision without altering the structure of the material with a good rate of manufacture, swiss machining is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our swiss cnc machining service is used to produce a variety of custom-designed cnc swiss machining parts and products in all areas of the industry:

What is Swiss Screw Machining

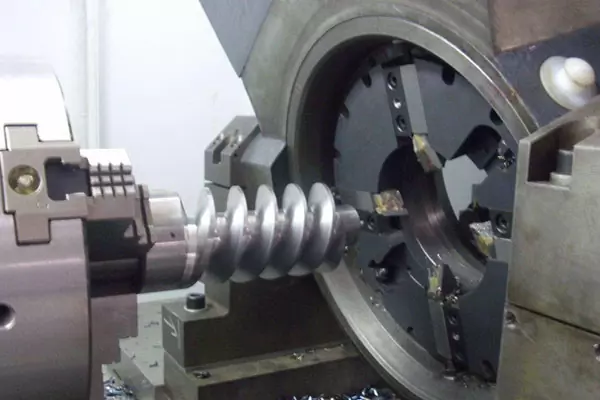

The full name of Swiss Machine is swiss type machine Or swiss screw machine. Traditional lathes use the method of cutting tools. Through the rotation of the spindle and the movement of the tools in all directions, the machining process of the parts is achieved. The Swiss Machine tool does not need to rotate and switch the tool, just move the props up and down, left and right, and the parts can be processed through the rotational movement of the spindle, and can be fed multiple times. The chip tool has always been processed at the spindle and workpiece clamping parts, which ensures the constant processing accuracy. The maximum processing diameter of the Swiss Machine on the market is 38mm, which has a great advantage in the precision shaft processing market. This series of machine tools can be equipped with an automatic feeding device to realize fully automatic production of a single machine tool and reduce labor costs and product defect rates. Therefore, compared with the traditional lathe, the Swiss Machine can use the center guide sleeve to make the produced products with higher precision, thus realizing the greater advantage in the processing of slender shaft parts.

Swiss Machine is generally used to process small parts from bars, with large batches, many of which are formed at one time. As long as it involves bar processing, if the diameter (not more than 32) is not too large, the advantage of the center lathe with the feeder is great (because the Swiss Machine must be equipped with a feeder for processing), so he is a small Independent production lines have advantages in terms of processing speed and labor costs. The main difference is: the Swiss Machine is the material moving, the knife moving machine is the knife moving, the old name of the Swiss Machine in China should be the slitting lathe. Mainly used for holding small parts and mass processing.

Difference Between Swiss Machine and Lathes

Compared with CNC lathes, Swiss Machine has made a qualitative leap in machining efficiency and machining accuracy. Due to the use of two-axis arrangement of tools, the machining cycle time is greatly reduced. The table overlap function, the thread chip effective axis movement overlap function, and the direct spindle indexing function during secondary machining can shorten the idle time. When moving, it can move according to the direction of Z2, X2 and C2 axes, and it can move freely in various directions. The machining on the corresponding tool holder is performed on the secondary axis, and a special control channel separate from the main axis is used during machining, which can achieve complementary intervention with the main axis. In the actual application process, the two axes All of them need to be processed at the same time, and this way of operation can effectively shorten the overall processing efficiency of the product.For Swiss Machines, the biggest limitation is the diameter of the rod material. At present, the largest type of centering lathe can only process parts with a diameter of 20 mm. The Swiss Machine newly developed by Shanghai Sigma adopts Korean technology and can process parts with a maximum diameter of 32 mm. As long as it is a part that can be machined by Swiss Machine, its machining accuracy, machining speed, and cutting machine cannot compare with it. Swiss Machine has many advantages, but its main advantage is that the spindle can cut parts up to 200mm in length without stopping in one clamping of the part. If you need to machine a relatively small part (10mm), both the Swiss Machine and the cutter can do it. However, the Swiss Machine can machine a lot of these small parts at one time without stopping the spindle, but the cutter can’t. In the process of cutting, the position that Swiss Machine cuts is often at the nearest position where the part is fixed, so the rigidity is very good.

The Case Studies Of Swiss Machining Parts

You have a complex part design, Our swiss machining service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Swiss Turning Stainless Steel 17-4 PH Positioning Bushing

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Swiss CNC Machining And Turning Brass 360 Shaft

-

Deep Hole CNC Turning Titanium Alloy Dispensing Needle

-

Precision Turning TC4 Alloy Medical Ultrasound Bead Needle

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

Swiss Turning Gold-Plated T2 Copper Parts

-

Swiss Machining Stainless Steel Pin Cylindrical Discharge Needle

-

Precision Swiss Machining Tooth Drive Screw Rod

-

Cnc Swiss Machining Stainless Steel 304 Taper Needle