CNC Turning

- Free shipping by DHL.FEDEX.UPS

- Global delivery as fast as 10 days,Machined prototypes in as fast as 1 days.

- 100+metals and plastics

- Tolerances down to +-0.01mm

- ISO 9001:2015, ITAF 16949

>>>All uploaded drawings are strictly confidential, check the confidentiality agreement

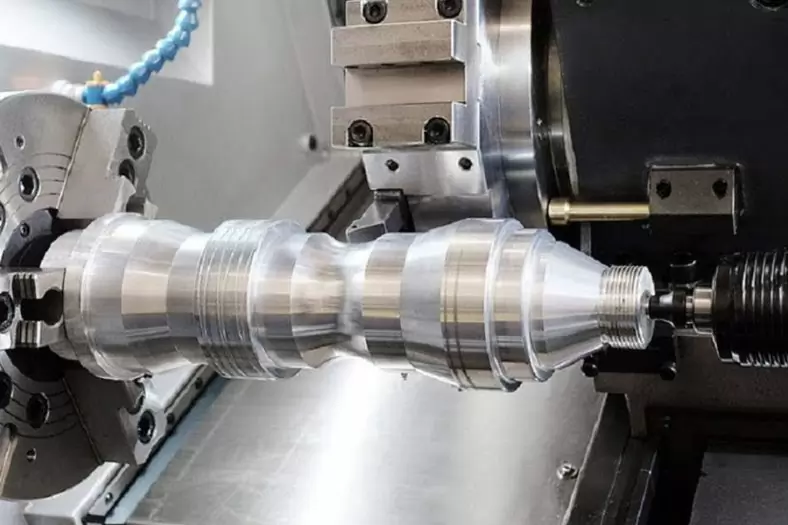

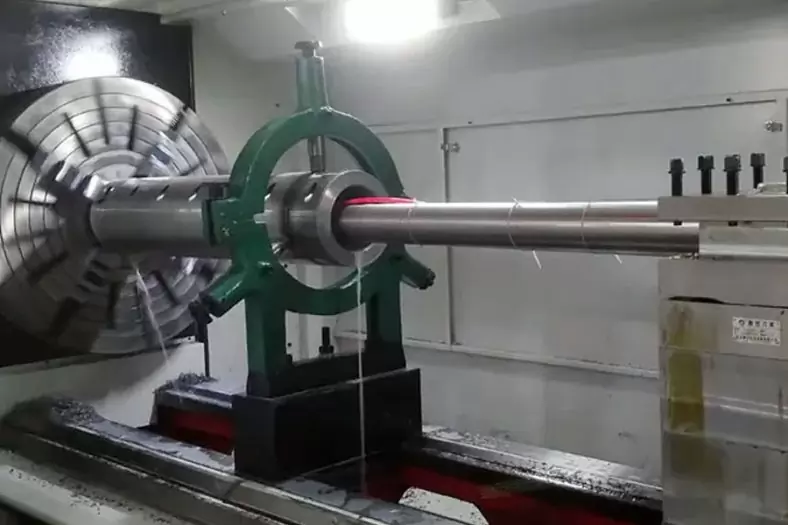

Online CNC Turning Services

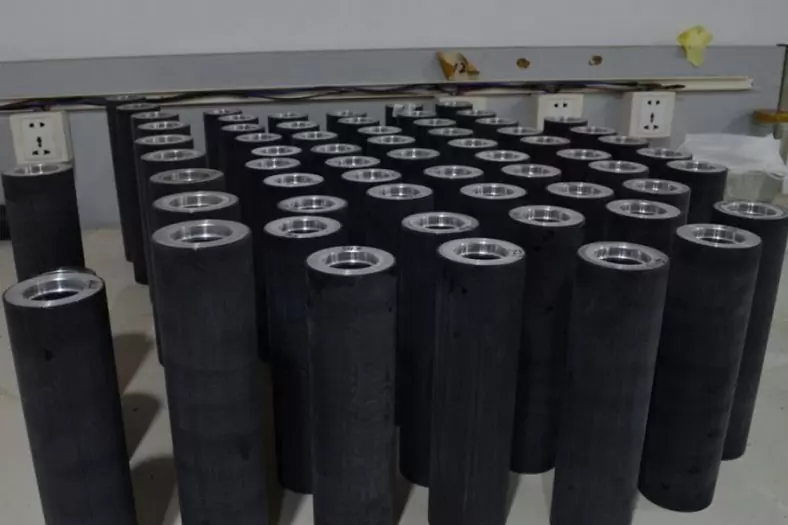

Want to shorten production cycle and reduce cost of your machinery components? Integrated multiple advanced technologies, CNC Turning Services can simplify the manufacturing process and speed up large batch production of machined components, as well as achieve a higher level of accuracy and precision.Be-cu provides rapid online CNC turning according to customer requirements. Send your CAD files or inquiry to us, a fast, free online CNC quote of required CNC components will be back. Get your CNC Turning Parts into processing in the shortest time.

Precision CNC Turning Services – Custom China CNC Turning Parts Manufacturer & Factory

BE-CU.COM – As an accomplished CNC Turning Company and CNC shop, Be-cu Rapid Prototyping Company has been specialized in OEM CNC lathing, custom CNC Turning parts production and rapid CNC Turning services China for over 30 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC lathing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, we passed the ISO9001:2015 quality certification, which supports the long-term development of Be-cu CNC Turning services, ISO turning, grooving, parting, thread turning, precision turning services, CNC Turning China custom parts and service, small parts turning, etc. Be-cu professional CNC parts turning involves CNC metal turning, plastic CNC Turning, and some difficult materials. Our CNC turning products can be utilized in a broad range of industries.

Be-cu CNC Turning Services Capabilities

As one of the fastest-growing precision CNC Turning services China suppliers, the following machining capabilities at Be-cu are available to serve your needs of CNC turned parts, from rapid prototyping to precision parts, to end-use production.

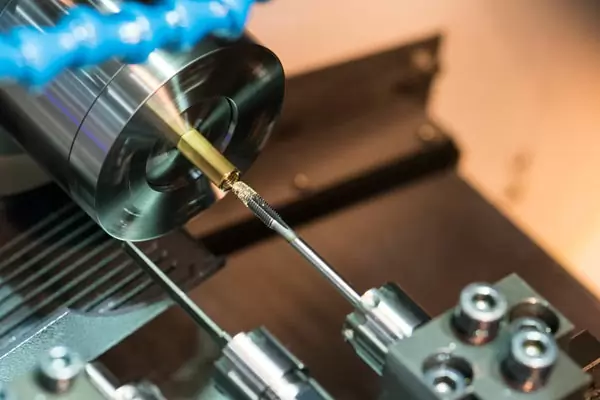

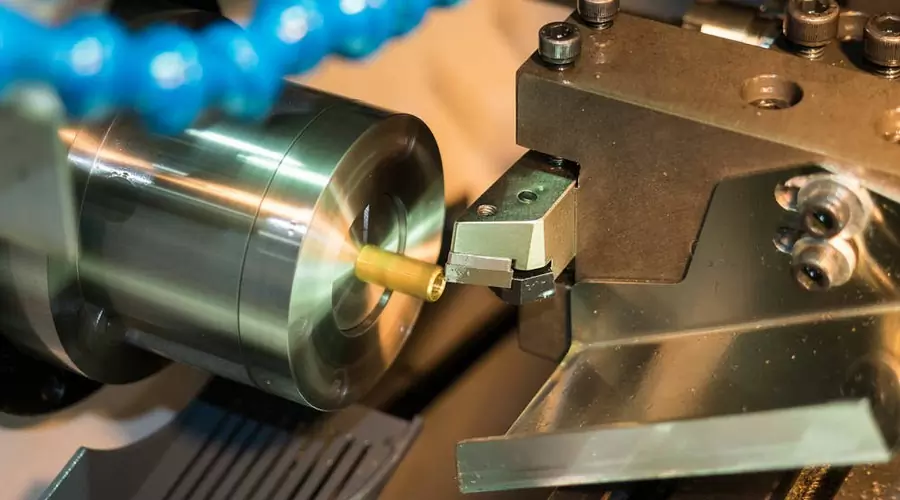

- Whether with conventional lathes and automatic lathes or with state-of-the-art CNC-controlled turning and machining centres :The Be-cu Cnc Turning Service that meet the highest demands for all production processes involved in metal turning.

- For you, this means: Maximum flexibility, stability, productivity and repeatability on any lathe. And top-class results for any workpiece.

- To achieve high wear resistance, long tool life and high cutting speeds when machining turned parts, all tools are made from specially alloyed cutting tool materials.

- Each of these are tailored to the material to be machined and have the best coatings for the material in question.

- The advantages for you: High process reliability, as well as an excellent surface finish quality and dimensional stability on the component.

- The sophisticated form and geometry of our turning tools also play a part in achieving maximum precision for your workpieces.

CNC Turning Metals

- Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

- Alloy: brass 360, 101 copper, 110 copper, 932 bronze, zinc, etc.

- Titanium: grade 2, grade 5, etc.

- Stainless steel: 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, etc.

- Steel: 4140, 4130, A36, 1018, etc.

CNC turning plastics

- Plastic: POM (Delrin), ABS (Acrylonitrile Butadiene Styrene), HDPE, Nylon, PLA, PC (Polycarbonate), PEEK (Polyether Ether Ketone), PMMA (Polymethyl Methacrylate or Acrylic), PP (Polypropylene), PTFE (Polytetrafluoroethylene), etc.

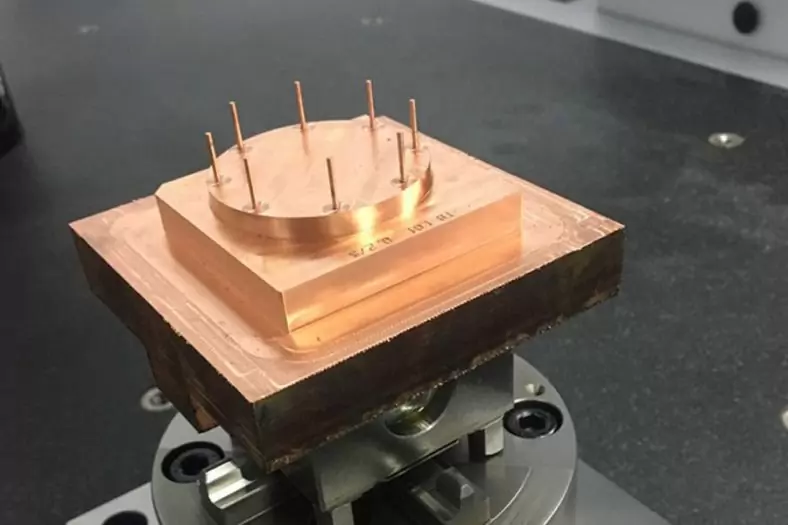

- Other CNC Turning materials: Graphite, VeroClear

Other CNC Turning Capabilities

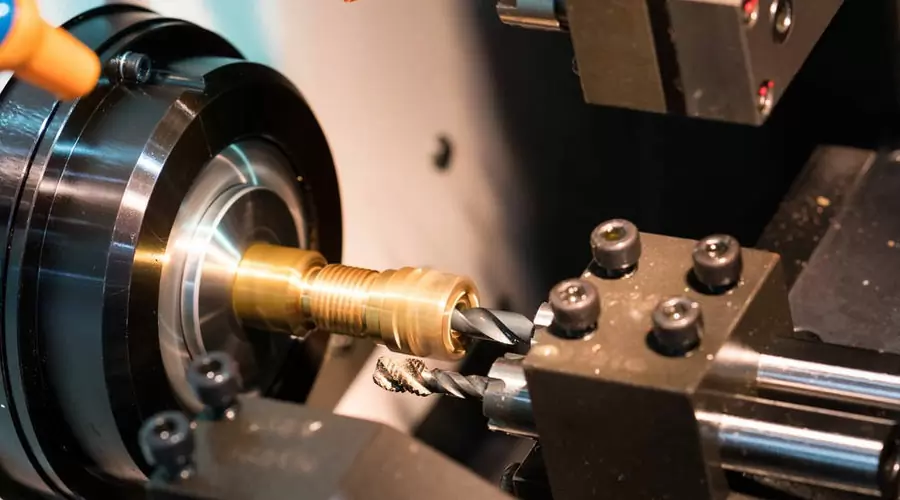

Driven by the idea of continuously perfecting turning, alongside cnc turning service Be-cu also offers you accessorial solutions that enable you to further optimise the production of your components using various methods, such as with Threading.

Drilling

We use various types of CNC drilling machines including upright, bench, radial, which allows us to drill holes of both simple and complex patterns up to 7 cm in diameter.

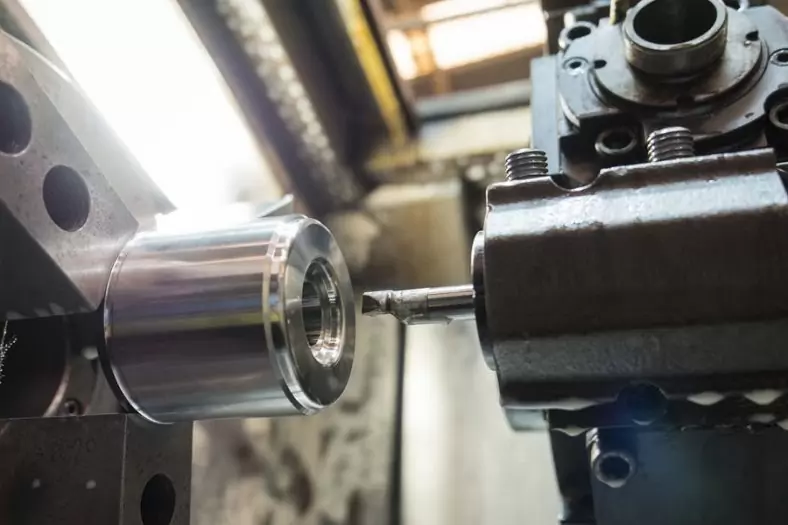

Boring

The powerful equipment CNC control and the rotary table for multi-sided machining of workpieces in one clamping offer solutions for a wider range of milling and drilling work.

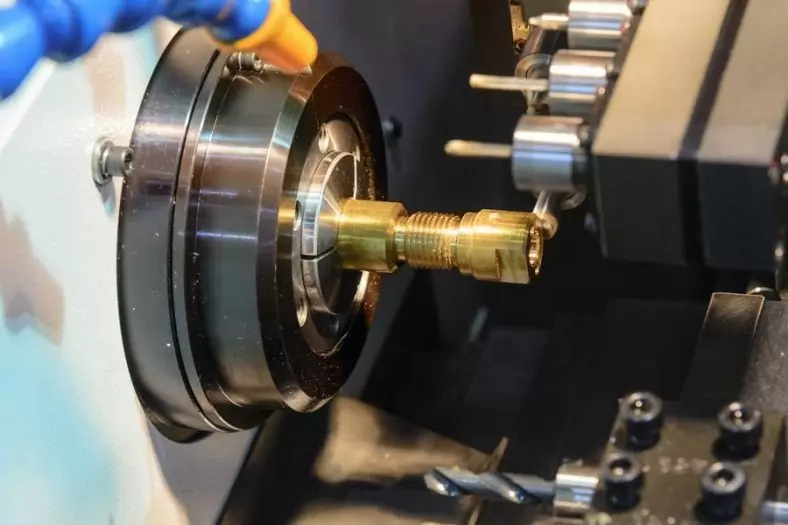

Threading

Thread cutting helps to create screwed connections on parts. Be-cu provides best thread turning services for the fabrication of both small and large series of parts of any complexity.

Knurling

Be-cu is an experienced knurling services supplier,Knurling is a process that creates a rough-textured pattern on ductile metals, usually for the purpose of enhancing grip and appearance.

CNC Turning Applications – What is CNC Turning Used for

Because the turning allows a very high precision without altering the structure of the material with a good rate of manufacture, CNC turning is becoming increasingly common as its machine range, control systems and cutting tools are just growing. Our CNC turning service is used to produce a variety of custom-designed CNC turning parts and products in all areas of the industry:

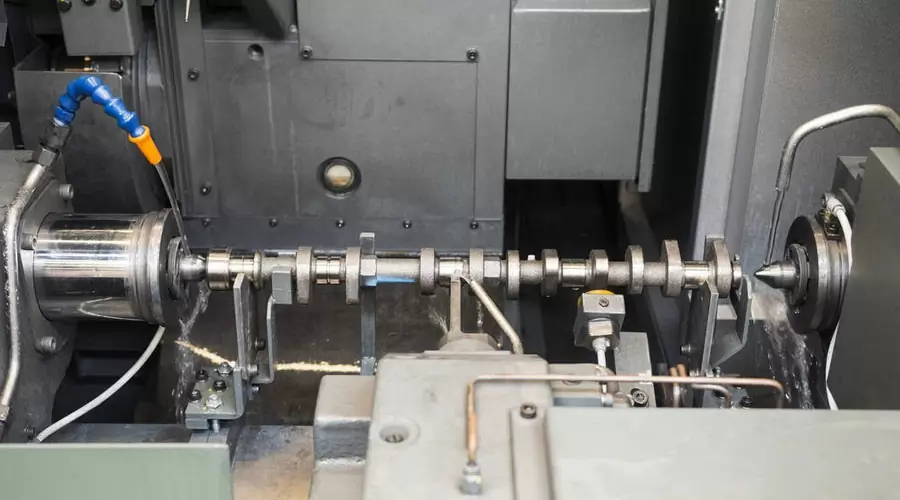

What is CNC Turning Center

CNC lathes can be divided into two categories: horizontal and vertical. There are two types of horizontal lathes: horizontal guide rails and inclined guide rails. Higher-grade CNC sleeper cars generally use inclined guide rails. According to the number of tool rests, it can be divided into single-tool rest CNC lathes and double-tool rest CNC lathes. The former is two-coordinate control, and the latter is four-coordinate control. Most of the double-tool rest cars use inclined guide rails.Like ordinary lathes, CNC lathes are also used to machine the rotating surface of parts. Generally, it can automatically complete the processing of outer cylindrical surface, conical surface, spherical surface and thread, and can also process some complex rotating surfaces, such as hyperboloids. The workpiece installation methods of lathes and ordinary lathes are basically the same. In order to improve processing efficiency, CNC lathes mostly use hydraulic, pneumatic and electric chucks.

The shape of the CNC lathe is similar to that of the ordinary lathe, that is, it is composed of the bed, the spindle box, the tool holder, the feeding system, the pressure system, the cooling and the lubrication system, etc. The feed system of CNC lathe is qualitatively different from that of ordinary lathes. Traditional ordinary lathes have feed boxes and exchange gear racks, while CNC lathes directly use servo motors to drive slides and tool rests through ball screws to achieve feed movement. The structure of the feeding system is greatly simplified.

The Difference Between CNC Lathe and Turning Center

- The economical CNC lathe is a simple CNC lathe formed by transforming the feeding system of the ordinary lathe with a stepping motor and a single-chip microcomputer. Turning of low-profile rotary parts.

- Ordinary CNC lathes are specially designed in structure according to the requirements of turning processing and are equipped with general CNC system. The CNC system has strong functions, high degree of automation and machining accuracy, and is suitable for turning of general rotary parts. This CNC lathe can control two coordinate axes at the same time, namely the X axis and the Z axis.

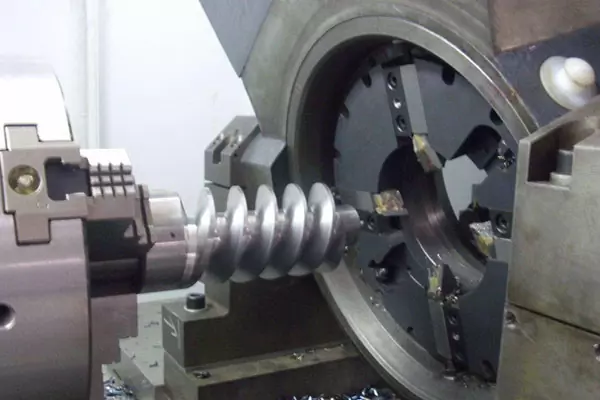

- On the basis of the ordinary CNC lathe, the turning machining center adds the C axis and the power head. The more advanced CNC lathe has a tool magazine, which can control the three coordinate axes of X, Z and C, and the linkage control axis can be (X, Z ), (X, C) or (Z, C). Due to the addition of the C-axis and the milling power head, the processing function of this CNC lathe is greatly enhanced. In addition to general turning, radial and axial milling, surface milling, holes and radial holes whose centerline is not in the center of rotation of the part can be performed. drilling, etc.

Cnc Turning Operations

- When turning a stepped shaft, in order to ensure the rigidity during turning, generally the part with a larger diameter should be turned first, and then the part with a smaller diameter should be turned.

- When grooving on the shaft workpiece, it should be carried out before finishing to prevent the workpiece from being deformed.

- When finishing a threaded shaft, generally the unthreaded part should be finished after threading.

- Before drilling, the end face of the workpiece should be turned flat. The center hole should be drilled first if necessary.

- When drilling deep holes, generally drill pilot holes first.

- When turning (Φ10—Φ20) mm holes, the diameter of the tool holder should be 0.6—0.7 times the diameter to be machined; when machining holes with a diameter greater than Φ20 mm, generally a tool holder with a clamping head should be used.

- When turning multi-start threads or multi-start worms, make trial cutting after adjusting the exchange gear.

- When using an automatic lathe, the relative position of the tool and the workpiece should be adjusted according to the machine tool adjustment card. After the adjustment, test turning should be carried out, and the first piece can be processed only after it is qualified; during the processing, always pay attention to the wear of the tool and the size and surface roughness of the workpiece. Spend.

- When turning on a vertical lathe, after the tool rest is adjusted, the beam should not be moved at will.

- When the relevant surface of the workpiece has positional tolerance requirements, try to complete the turning in one clamping.

- When turning cylindrical gear blanks, the hole and the reference end face must be machined in one clamping. If necessary, a marking line should be drawn near the gear index circle on the end face.

The Case Studies Of Cnc Turning Parts

You have a complex part design, Our Cnc Turning service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Custom Aluminum Alloy 7075 Tattoo Machine Shell By Cnc Turning

-

Precision Cnc Turning Stainless Steel 316 Machine Screw

-

Cnc Turning Machining Brass Alloy LED Chandelier Accessories

-

Cnc Turning Custom 3W LED Showcase Light Brass Alloy Housing

-

Cnc Turning 3W Brass Showcase Lighting Enclosure

-

Custom LED Grow Light Ring Brass Accessories By Cnc Turning

-

Precision Turning Machining Brass LED Light Accessories

-

Custom Electric Nail Polisher Machine Parts By Cnc Machining

-

Automatic Swiss Cnc Machining Stainless Steel 316 Special Long Screw

-

Oil Press Machine Spindle Accessories For Home Application