Precision CNC Turning Aluminum

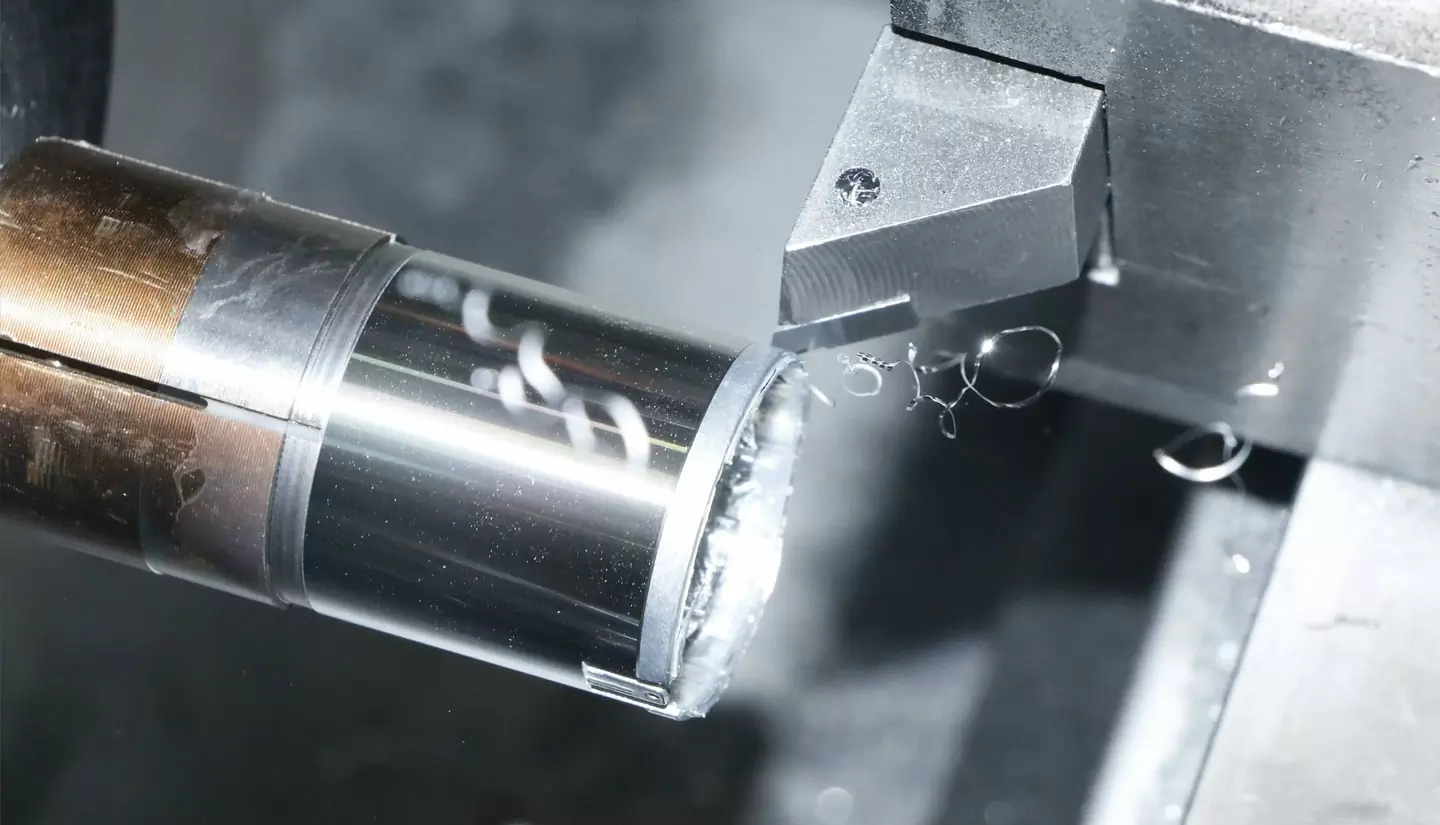

Aluminum CNC turning is a particular form of aluminum precision machining in which a cutter removes material by making contact with the spinning aluminum parts. The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability.

Deformed aluminum alloys in various states have low strength and hardness, and the cutting difficulty lies in their high plasticity, which is not easy to break chips. It is easy to form a built-up edge during cutting, and it is difficult to obtain a good surface quality.

Cast aluminum alloys have low plasticity and most of them have good machinability. Since most of the cast aluminum alloys contain silicon, their cutting performance is related to the silicon content. The higher the silicon content, the more serious the tool wear and the worse the machinability.

From the machinability of aluminum alloys, it can be seen that no matter the precision of the parts or the surface roughness, the grinding process cannot be used. To ensure the accuracy, surface roughness and processing efficiency of the workpiece during processing, the tool requires good wear resistance.

BE-CU uses diamond tools, which have good wear resistance and are suitable for high-speed turning and improve efficiency. The workpiece is processed by one-time clamping with a three-grip chuck, and the spindle speed is increased to appropriately increase the amount of eaten knives or low-speed snack knives.

Cnc Turning Aluminum Services – Custom Aluminum Alloy CNC Turning Parts

Looking for reliable, quick-turn Cnc Turning Aluminum services suppliers and CNC turning product manufacturers?CNC turning machines are ideal for creating round or cylindrical parts. Lathes create these parts quickly, accurately and with excellent repeatability.We offering multi-axis precision CNC turning services for 6061,6063,7075 and more aluminum alloys. Capable of machining parts up to 4 in. circumscribed dia., 0.040 in. minimum wall thickness and +/-0.002 in. tolerance. Milling, cutting, drilling, punching, welding and tapping services provided. Deburring and grinding services also offered. Prototype and low to medium volume production runs. Serves the aerospace, automotive, construction, electronics, telecommunication, medical equipment, firearm, home and sport industries. AutoCAD and SolidWorks® files accepted.

Why Choose Our Aluminum Cnc Turning Service?

- Save time and money for your aluminum project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be machined

- Custom complex aluminum machined parts and components at specific tolerances

- High speed cnc turning for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Aluminum Cnc Turning Case Studies

Cnc Turning processes such as precision turning and swiss turning are today considered the most economic way to make aluminum prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making aluminum Concept models and precise functional components. Understanding the properties of different aluminum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on aluminum alloy. Be-cu prototyping company provides a range of solutions for the turning of aluminum parts.

-

CNC Turning 6063 Bicycle Tightening Disc

-

Custom Aluminum Alloy 7075 Tattoo Machine Shell By Cnc Turning

-

Custom Electric Nail Polisher Machine Parts By Cnc Machining

-

CNC Machining Precision Aluminum Alloy Auto Parts

-

Precision Turning Aluminum Alloy 7075 Parts

-

Oil Press Machine Spindle Accessories For Home Application