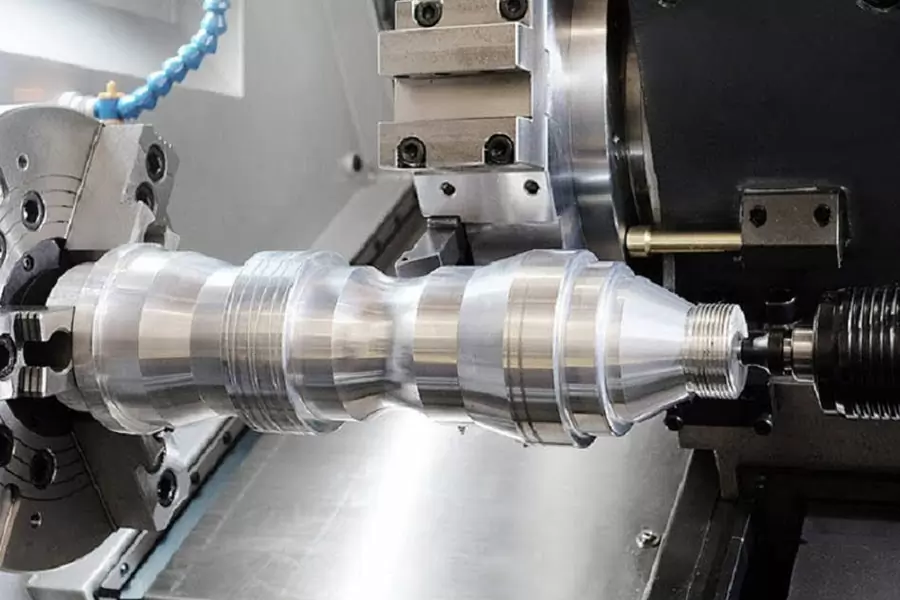

Precision CNC Turning Titanium

Titanium turning services generally is used to produce critical aerospace components and medical devices. It offers a high strength-to-weight ratio and excellent corrosion resistance, which enables it to be used for designs with thin walls.

The thermal conductivity of titanium alloy is very poor, and the contact length between the chip and the tool is very short, which is not conducive to the export of cutting heat, so that the temperature of the cutting edge area is high, which is about twice as high as that of cutting 45 steel. In addition, the tool wear is also very serious. On the one hand, the titanium alloy has a strong chemical affinity with the tool material, and it is easy to bond with Ti, Co, C and other elements in the tool material, and the bonding wear is aggravated at high temperature; The alloy is easily combined with oxygen and nitrogen in the air to form a hard and brittle surface layer, which increases tool wear.

In addition, since the contact length between the chip and the rake face of the tool is only 1/3~1/4 of the cutting steel, the cutting force is concentrated near the cutting edge, and the tool is prone to chipping. Therefore, the tool material for cutting titanium alloys, such as high-speed steel, should be high-speed steel containing cobalt, aluminum or high vanadium.In order to improve production efficiency, BE-CU.com uses high-strength fine-grained tungsten-cobalt carbide tools with low affinity for titanium alloys and good thermal conductivity for titanium alloy turning process.

Cnc Turning Titanium Services – Custom Titanium Alloy CNC Turning Parts

Looking for reliable, quick-turn Cnc Turning Titanium services suppliers and CNC turning product manufacturers?

3, 4, 5, 7 and 11-axis precision CNC turning services for titanium. Capable of machining parts from 0.5 to 18 in. dia. Capable of handling parts up to 60 in. L x 120 in. W sizes with thickness up to 1/4 in. and tolerance up to +/-0.003 in. Processes include boring, broaching, drilling, knurling, tapping, reaming, cutting, milling, threading and turning. Prototype and low to high volume production offered. Suitable for surgical instrument, aircraft, armor plating, naval ship, spacecraft and missile applications. AutoCAD and SolidWorks® files accepted.To discover the more general advantages of CNC machining with BE-CU.COM, see our CNC machining services page.

Why Choose Our Titanium Cnc Turning Service?

- Save time and money for your titanium project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of titanium grades and alloy materials can be machined

- Custom complex titanium machined parts and components at specific tolerances

- High speed cnc turning for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Titanium Cnc Turning Case Studies

Cnc Turning processes such as precision turning and swiss turning are today considered the most economic way to make titanium prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making titanium Concept models and precise functional components. Understanding the properties of different titanium alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on titanium alloy. Be-cu prototyping company provides a range of solutions for the turning of titanium parts.