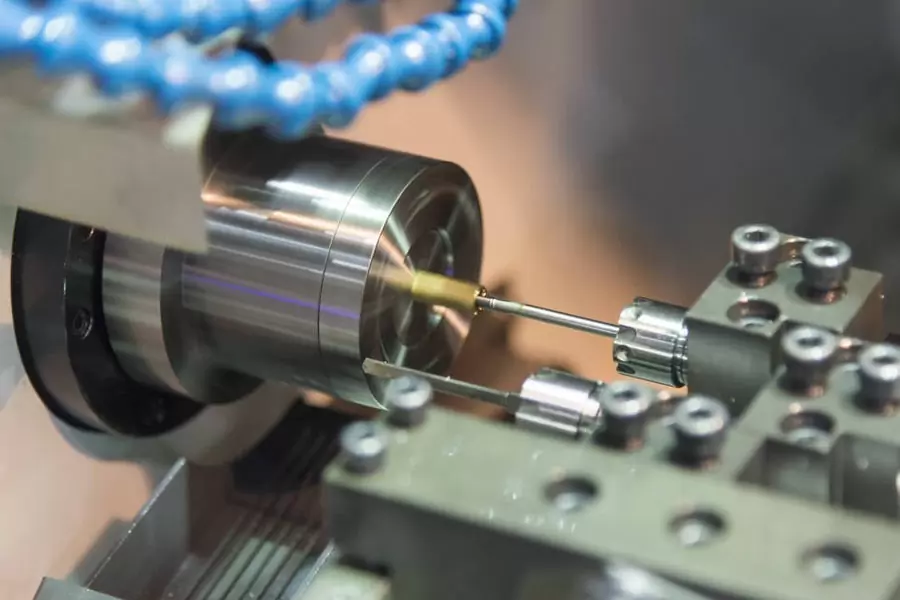

The Experience For CNC Turning Copper Parts

Commonly cnc machined coppers include brass and red copper, which are relatively hard compared to brass and softer than red copper. When processing brass, the requirements for turning tools are not very high, while when processing red copper, the tools must be sharp and the cutting grooves must be large. Otherwise, copper shavings are easy to wrap around the tool and scratch the surface of the workpiece. The number of revolutions required for brass is higher than that of copper. And brass processing generally does not require coolant, while copper requires a coolant that does not contain sulfur, phosphorus, and chlorine. Taking YG tools for processing brass as an example, set the cutting parameters as (25mm diameter brass, 1200r/min rotation speed, 2mm cutting length, and 150mm/min feed rate)

The copper machined by BE-CU is all free-cutting copper, and the tool materials can be high-speed steel knives, carbide YG knives, and diamond knives. Since there are many types of copper alloys, reasonable tools should be selected according to their characteristics, usually YG tools are used.

Cnc Turning Copper Services – Custom Copper Alloy CNC Turning Parts

Looking for reliable, quick-turn Cnc Turning Copper services suppliers and CNC turning product manufacturers?

CNC turning services for copper parts. Capable of turning parts from 1/16 to 22.5 in. length, 1/16 to 13 in. dia. and up to +/-0.0005 in. straightness tolerance.Other processes include boring, broaching, counterboring, drilling, milling, knurling, profiling, reaming, tapping and threading. Secondary services such as anodizing, assembly, grinding, etching, passivating, plating, heat treating and lapping provided. Small to medium volume production offered with maximum 50,000 units.We have provided precision copper cnc turning for applications such as engine components, turbine components, construction equipment, forgings, valves, sockets, bushings, and more. Most of our work is performed within 1 to 2 weeks depending on complexity, with rush services also available. For more information, check the cnc turning services or contact us directly.

Why Choose Our Copper Cnc Turning Service?

- Save time and money for your copper project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of copper grades and alloy materials can be machined

- Custom complex copper machined parts and components at specific tolerances

- High speed cnc turning for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Copper Cnc Turning Case Studies

Cnc Turning processes such as precision turning and swiss turning are today considered the most economic way to make copper prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making copper concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on copper alloy. Be-cu prototyping company provides a range of solutions for the turning of copper parts.

The Amount Of Cutting Tools, Feed And Speed Of CNC Turning Copper

The cutting amount of CNC turning copper parts is 3-4 mm, the feed is 0.25, and the speed is determined according to the diameter.

- The spindle speed of the CNC lathe is determined according to the material of the workpiece to be processed and the material of the tool. Usually, the higher the speed, the better the finish.

- Usually, the high speed is not suitable for choosing a large amount of knife. You can choose a larger feed, and the medium and low speed make the machine tool have a larger torque, which is suitable for a large knife, and the feed should not be too fast. The feed is large, and the knife is best to be smaller. These are related to the machine tool, the stiffness of the tool, and the properties of the metal material.

- Rough machining is generally based on improving productivity, but economy and processing costs should also be considered; semi-finishing and finishing should take into account cutting efficiency, economy and processing costs under the premise of ensuring processing quality.

- The feed rate is the relative displacement of the workpiece and the tool in the direction of feed movement when the workpiece or tool rotates once or reciprocates once or when the tool rotates one tooth.