What Is 3D Laser Cutting

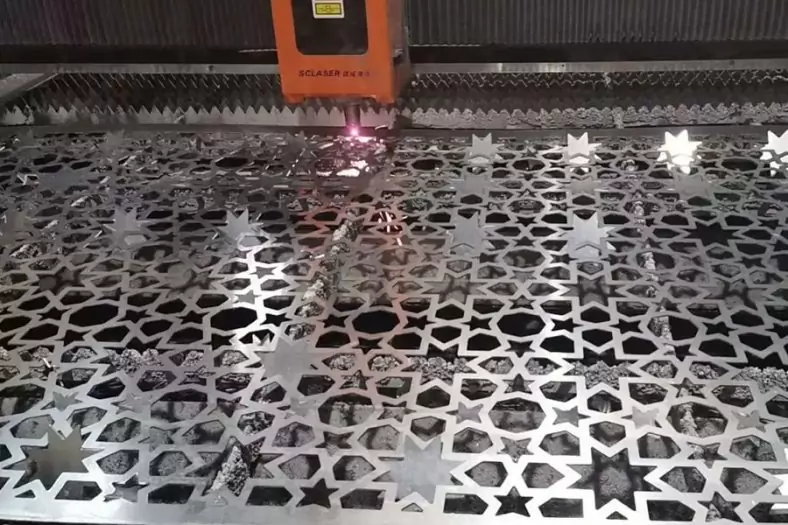

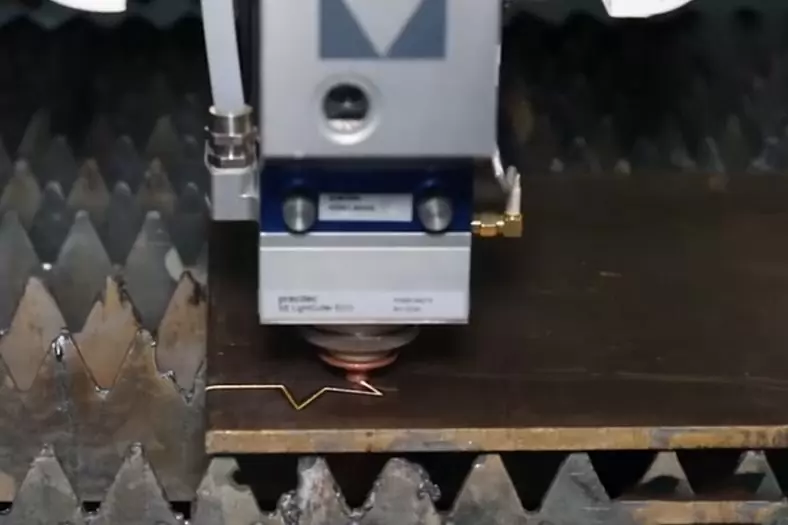

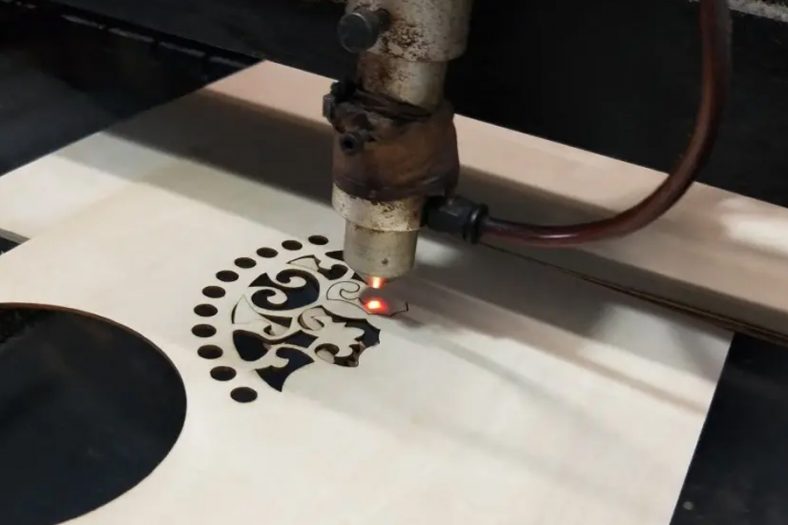

3D laser cutting is a cutting-edge technology that takes the precision and versatility of laser cutting to a whole new dimension, quite literally. While traditional laser cutting primarily operates in two dimensions, focusing on flat materials, 3D laser cutting extends this capability to handle three-dimensional objects, opening up a wide range of applications in various industries.At its core, 3D laser cutting utilizes a high-powered laser beam to remove material from an object to create intricate and complex shapes. However, what sets 3D laser cutting apart is its ability to manipulate the laser beam in multiple directions, allowing it to cut, engrave, or mark a three-dimensional workpiece.

This means that 3D laser cutting machines can handle not only flat sheets of material but also complex, irregular, and three-dimensional structures with ease.The process involves the use of a computer-controlled system that precisely positions the laser beam in three-dimensional space. The laser beam can move along the X, Y, and Z axes, allowing it to cut and shape intricate designs on various materials, including metals, plastics, ceramics, and composites. The result is a level of precision and intricacy that would be challenging to achieve with traditional cutting methods.

Comparison with 2D Laser Cutting and Other Traditional Cutting Methods

To truly appreciate the significance of 3D laser cutting, it’s important to contrast it with 2D laser cutting and traditional cutting methods.

2D Laser Cutting vs. 3D Laser Cutting:

2D laser cutting is a widely used technology, particularly in industries like sheet metal fabrication. It excels at cutting flat materials to create 2D shapes. In contrast, 3D laser cutting offers the added capability of working on three-dimensional objects. This opens up the possibility of creating complex 3D shapes and intricate designs that 2D laser cutting simply cannot achieve.

In 2D laser cutting, the material to be cut is placed flat on a cutting bed, and the laser beam is focused solely on the plane of the material. In 3D laser cutting, the laser head can move not only in X and Y but also in the Z-axis, allowing it to follow the contours of the workpiece. This is especially advantageous when dealing with curved or contoured surfaces, such as automotive components or intricate prototypes.

Traditional Cutting Methods:

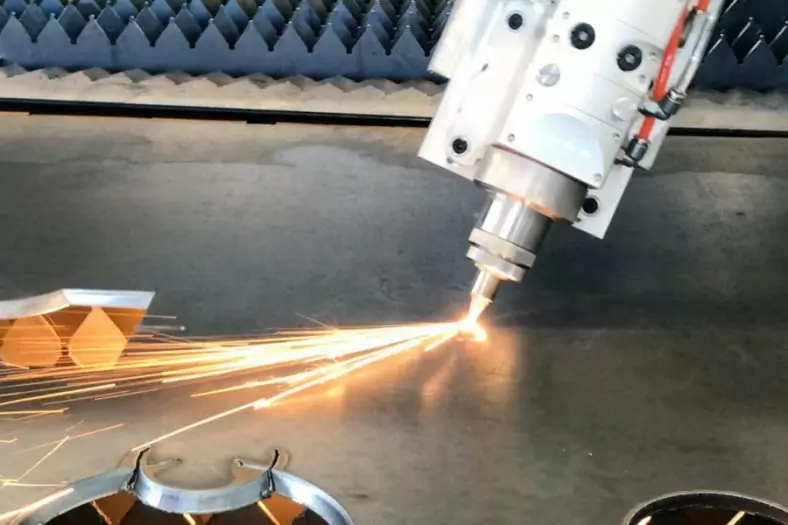

When compared to traditional cutting methods, which often involve manual processes like sawing, drilling, or milling, 3D laser cutting stands out for its precision and automation. Traditional methods are often labor-intensive, time-consuming, and may result in a significant amount of material waste. 3D laser cutting, on the other hand, offers the ability to create precise, intricate cuts with minimal material waste, making it both cost-effective and environmentally friendly.

3D Laser Cutting Services – Online 5 Axis 3D Cutting Suppliers

Be-Cu prototype has provided global client with the highest quality 3d laser cutting and prototype services since 1995. 5-axis cut is a more effective method for fabrication complex sheet metal parts,is used to cut slots, holes, corners, and other features in parts such as tubes, channels, angles, and beams.We specialize in true 5 axis precision laser cutting, delivering hard to make 5-axis cut components and metal fabricators with ease.

As one of the best laser cutting manufacturers in China, Online 5 axis laser cutting making it an excellent choice for rapid prototyping and low to high volume production runs, instant 3d laser cut parts quotes,10+ surface finishes.We provides laser cutting for a wide variety of materials, including steel, stainless steel, aluminum, non-ferrous metals, and more. Our Germany Jenoptik Robot and two dazhu 3d laser cutters give us the capability to handle high-volume production runs with accuracy and efficiency. We utilize the latest 3D laser technologies to provide our customers with parts that meet or exceed their expectations. We deliver value on all of our projects with unmatched quality products supported by superior customer service at competitive prices.

Engineers, innovators, maintenance managers and others choose Be-Cu for custom 3D Laser cutting, because we are able to effectively and accurately metal fabrication, with absolutely no minimum orders. At Be-Cu.com, you don’t have to worry about dealing with a machining-shop queue, or your small-quantity order being bumped for a production run.We pride ourselves on our reliability and superior customer service. Contact us to get started.

3D 5-Axis Cutting Capabilites

- Custom shapes and complex geometries

- High repeatability in production

- Parts up to 60” x 120” x 40”

- Maximum thickness to 0.394″

- Tolerances to +/-.010″, up to +/-.005″ for certain parts and material

- Minimal work hardening and metal distortion on completed parts

Accepted File Types

- Vector Files:Give us a pre-designed file in vector format, and we can convert it into a finished product.Typical Vector File Types: (DXF, DWG, SVG, etc…)

- Raster Files:If you are providing a design that is not in vector format such as an image or a sketch, you may be required to pay for design work.Typical Raster File Types: (JPEG, PNG, etc…)

3D Laser Cutting For Automotive

The sheet metal covering parts of automobile parts include hoods, rear lid boxes, radiator frames, bumpers, fenders, doors, as well as ingot beams of chassis parts, control arms, rear axles and high-pressure formed tubes of cab frames, etc. Three-dimensional cutting is often required, including trimming and punching. Traditional processes include die stamping, plasma cutting, mechanical engraving and milling, etc.

The Be-Cu prototype is processed using a combination of industrial robots and fiber lasers, and processes such as trimming and punching are completed in one go. The cuts are neat and require no subsequent processing. It greatly shortens the process flow, reduces labor costs and mold expenses, and also improves the grade and added value of the product.

Certifications & Quality Cutting

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Metal Material Of 3D 5 Axis Laser Cutting

Metal material can be easily machined and have a low raw material cost, making them often the most economical choice for prototyping and 3d laser cutting.There are a few factors to consider when choosing the right metal for 3d Laser Cutting. The metal you choose is critical to your ultimate success. For example, metals may need to withstand high temperatures or bend or break under pressure. When choosing the right metal, corrosion resistance, machinability, price, weight and visual appearance all play a role.

Top China Pipe/Plate/Sheet 3D Laser Cutting Case Studies

Laser cutting processes such as fiber laser cutting , Co2 laser cutting and 3D laser cutting are today considered the most economic way to make metal prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sheet metal is the only option. Our company has rich experience making metal concept models and precise functional components. Understanding the properties of different metal material, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on metal material. Be-cu prototyping company provides a range of solutions for the cutting of Metal Parts.