Laser Cutting For Nitinol

Nitinol, a unique alloy composed of nickel and titanium, exhibits remarkable properties such as shape memory and superelasticity. These characteristics make Nitinol a popular choice in various industries, including medical devices, aerospace, and robotics.

Micro Laser cutting has emerged as a preferred method for processing Nitinol due to its precision, minimal thermal impact, and versatility in creating intricate shapes. Micro Laser cutting nitinol parts are extremely durable, but it can be challenging to machine nitinol due to its high tensile strength. In this article, we will provide great information on laser cutting nickel-titanium, how to choose the right cutting tools for cut nitinol, and useful tips to ensure successful micro laser cut.

What Is Nitinol – The Define Of Nickel-Titanium

Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a shape memory alloy (SMA) with the ability to return to a predetermined shape when exposed to a specific temperature or stress. This unique property has led to the integration of nitinol in laser cutting medical devices like stents, guidewires, and orthodontic archwires, as well as applications in aerospace and robotics.

Why Choose Nickel-Titanium for Your Custom Parts

Here is a table summarizing the physical and chemical properties of Nitinol:

| Property | Description |

|---|---|

| Chemical Composition | Nickel (Ni) and Titanium (Ti) alloy |

| Crystal Structure | Austenitic at higher temperatures, Martensitic at lower temperatures |

| Density | Approximately 6.45 g/cm³ |

| Melting Point | Around 1,300°C (2,372°F) |

| Young’s Modulus | Varies based on the specific composition, typically in the range of 70-90 GPa |

| Coefficient of Thermal Expansion | Varies based on temperature and phase, typically around 10-20 x 10^-6 /°C |

| Thermal Conductivity | Approximately 20-30 W/(m·K) depending on the specific alloy composition |

| Specific Heat Capacity | Around 0.46 J/(g·K) for austenitic phase, higher for martensitic phase |

| Electrical Conductivity | Good electrical conductivity, suitable for electronic applications |

| Corrosion Resistance | Exhibits excellent corrosion resistance, making it suitable for use in various environments |

| Shape Memory Effect | Demonstrates a reversible shape memory effect, returning to a predetermined shape upon heating |

| Superelasticity | Displays superelastic behavior, allowing for significant deformation and recovery under stress/strain |

| Biocompatibility | Biocompatible, making it suitable for medical applications such as stents and guidewires |

| Ductility | Ductile material that can be easily drawn into thin wires |

| Fatigue Resistance | High fatigue resistance, capable of withstanding repeated cycles of deformation and recovery |

| Tunable Transformation Temperatures | Transformation temperatures can be adjusted by varying the alloy composition |

Temperature-Induced Transformation

Nitinol exhibits a phenomenon known as shape memory, wherein it can remember and recover its original shape when exposed to a specific temperature. This temperature-induced transformation is reversible, allowing Nitinol to repeatedly shift between two different forms.

Martensitic and Austenitic Phases

At lower temperatures (martensitic phase), Nitinol can be easily deformed and manipulated into a specific shape. When heated above a critical temperature, it reverts to its original shape (austenitic phase), showcasing its unique shape memory characteristics.

Superelasticity

Flexibility under Stress: Nitinol is also characterized by superelasticity, meaning it can undergo significant deformation and return to its original shape when the stress is removed. This property makes Nitinol highly resilient and ideal for applications where flexibility and durability are crucial.

Biocompatibility

Medical Applications: Nitinol is widely used in the medical field due to its biocompatibility and unique mechanical properties. It is commonly employed in medical devices such as laser cut stents, guidewires, and orthodontic archwires.

Tunable Transformation Temperatures

The transformation temperatures of Nitinol can be tuned by adjusting the alloy composition. This allows for customization based on specific application requirements.

Corrosion Resistance

Durability in Harsh Environments: Nitinol exhibits excellent corrosion resistance, making it suitable for applications in challenging environments, such as aerospace and marine industries.

What Are the Different Types of Nitinol?

The primary types of Nitinol are classified based on their transformation temperatures and specific alloy compositions. Here are some of the common types of Nitinol:

- Binary Nitinol (Ni-Ti):The most basic form of Nitinol is the binary alloy composed of nickel (Ni) and titanium (Ti). This alloy exhibits shape memory and superelasticity, making it suitable for a wide range of applications in various industries.

- Linear Transformation Temperature Nitinol:Linear transformation temperature Nitinol is engineered to have a linear relationship between temperature and phase transformation. This type of Nitinol allows for precise control over the transition temperatures, offering flexibility in tailoring the material for specific applications.

- Pseudoelastic Nitinol:Pseudoelastic Nitinol is characterized by its superelastic behavior, allowing the material to undergo significant deformation and recover its original shape upon the removal of stress. This type of Nitinol is commonly used in medical devices like stents and guidewires.

- Shape Memory Nitinol:Shape memory Nitinol is designed to exhibit the shape memory effect, where the material can “remember” and revert to a predetermined shape when subjected to a specific temperature. This type of Nitinol is used in applications where shape recovery is a critical feature.

- High-Temperature Nitinol:High-temperature Nitinol is engineered to have phase transformation temperatures above room temperature. This type of Nitinol is suitable for applications where higher temperatures are encountered, such as in aerospace components and actuators.

- Low-Temperature Nitinol:Low-temperature Nitinol is designed to have phase transformation temperatures below room temperature. This type of Nitinol is useful in applications requiring shape memory or superelastic behavior at lower temperatures.

- Custom Alloy Compositions:Engineers can tailor Nitinol alloy compositions to achieve specific properties or to address particular application requirements. Custom alloy compositions allow for optimization of material characteristics such as transformation temperatures, strength, and corrosion resistance.

- Medical-Grade Nitinol:Nitinol used in medical applications is often produced to meet stringent quality and biocompatibility standards. Medical-grade Nitinol is commonly employed in devices like stents, guidewires, and other implantable medical devices.

Nitinol Laser Cutting Service – Precision Cut For Nickel-Titanium

If you’re looking for Nitinol Laser Cutting, look no further than Be-Cu prototype.

We’ll explain everything you need to know about nitinol and its alloys, why nitinol laser cutting is being used in so many applications, what laser cutting is and how it’s the best manufacturing technique for nitinol, what you should consider when laser cutting nitinol parts, the variety of surface finishes available and how much laser cutting nitinol costs.

Nevertheless, it would help if you let trained experts carefully machine your grades of nitinol alloys for the best results because nitinol laser cutting requires the proper tooling, patience, and expertise. Hence, if you need the assistance of professionals in choosing the suitable nitinol alloy for your project, Be-Cu is your best bet.

Be-Cu is a reliable micro laser cutting and medical laser cutting service provider. Our skilled team provides a variety of Nitinol Laser Cutting techniques that will meet your needs.We offer a range of quality manufacturing capabilities with faster turnaround times. Our professional engineers and machinists have in-depth knowledge of the Nickel-Titanium cut services and parts to handle your prototyping and mass production. Let us handle your nitinol laser cutting, as we offer competitive prices.

Whether you need 10 custom parts, or 1,000,000, our precision machine shop can help maintain the quality and help you manage your supply chain efficiently. If precision and attention to detail are vital for the success of your medical laser cut industry project, we can deliver to your exact specifications.

The Case Studies Of Nitinol Laser Cutting

You have a complex nitinol parts design, Our nitinol laser cutting service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototype ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

Surface Finishes For Nitinol Laser Cutting

The surface finish for Nitinol laser cutting is an important consideration to achieve desired results. Nitinol, a nickel-titanium alloy, is known for its unique properties, including shape memory and superelasticity. When laser cutting Nitinol, the choice of surface finish can impact the quality of the cut and the overall performance of the material. Here are some common surface finishes for Nitinol laser cutting:

Smooth Finish

A smooth surface finish is often desirable for Nitinol components, as it can minimize surface irregularities and enhance the overall aesthetics.

Achieving a smooth finish can be important for medical devices or other applications where precision and cleanliness are critical.

Textured Finish

Some applications may require a textured or roughened surface for enhanced bonding or adhesion properties.

Textured finishes can be achieved through controlled laser processing techniques to create specific surface patterns.

Cleaned Finish

Nitinol laser-cut components may undergo a cleaning process to remove any residual debris or contaminants from the cutting process.

Cleaned finishes are important for applications where contamination could be detrimental, such as in medical implants.

Passivation

Passivation involves treating the Nitinol surface to enhance its corrosion resistance. This is particularly important in medical and aerospace applications.

Nitinol components may be passivated after laser cutting to improve their resistance to oxidation and other environmental factors.

Heat Treatment Finish

Laser cutting can introduce heat to the Nitinol material. A specific heat treatment finish may be applied to restore the desired properties of Nitinol, such as shape memory and superelasticity.

It’s crucial to work with experienced laser cutting service providers or manufacturers who are familiar with Nitinol’s properties and can recommend the most suitable surface finish based on the specific requirements of your application. Additionally, post-processing steps such as polishing or coating may be considered to further enhance the surface characteristics of Nitinol components after laser cutting.

Applications Of Nitinol Laser Cutting

Nitinol, a nickel-titanium alloy with unique shape memory and superelastic properties, has various applications in different industries. When it comes to laser cutting of Nitinol, the precision and efficiency of the process make it suitable for specific applications. Here are some notable applications of Nitinol laser cutting:

Nitinol Laser Cutting For Medical Devices

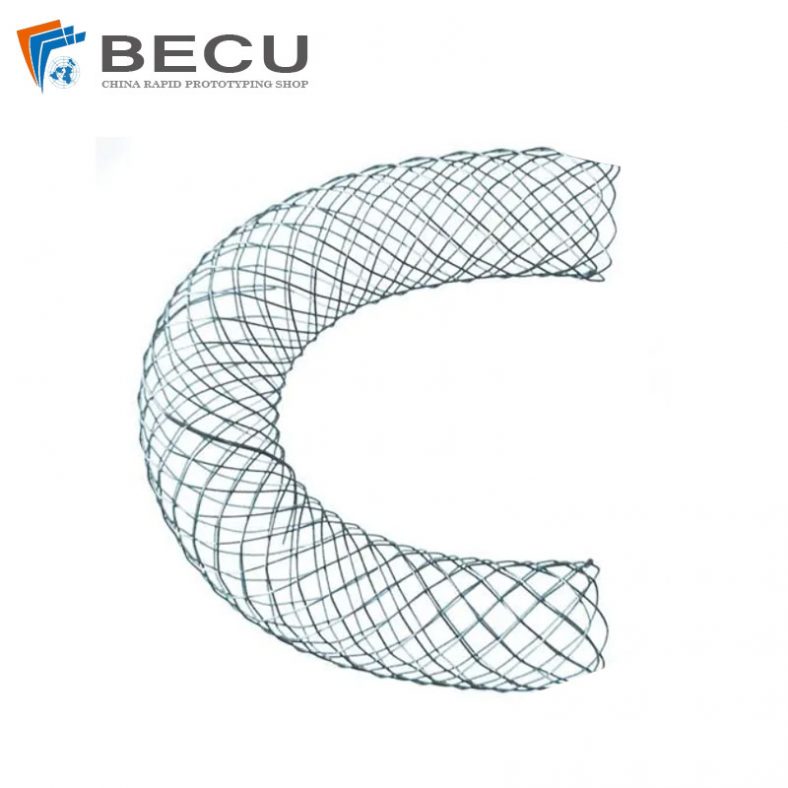

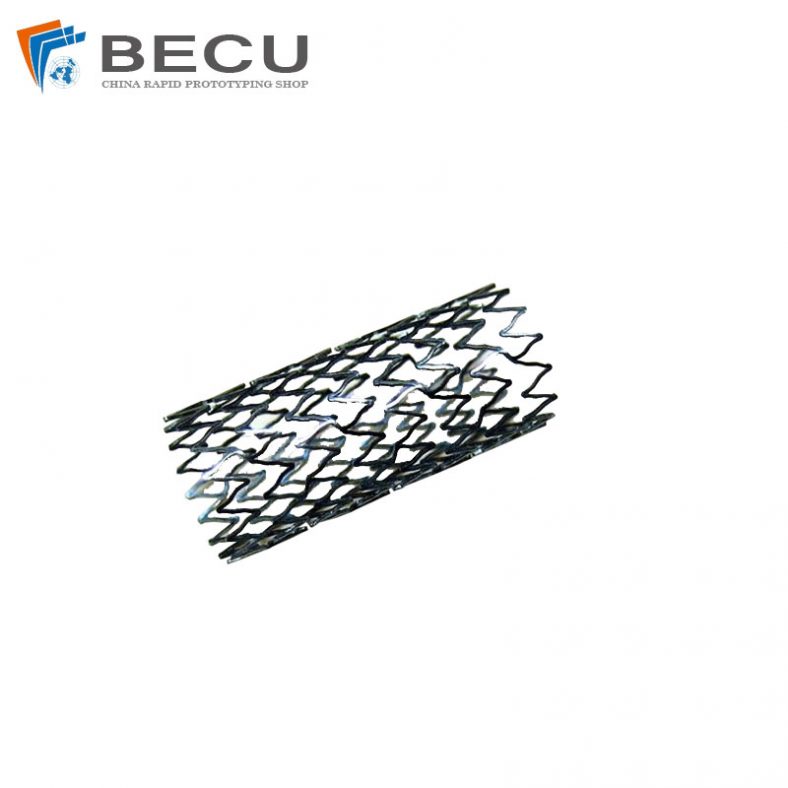

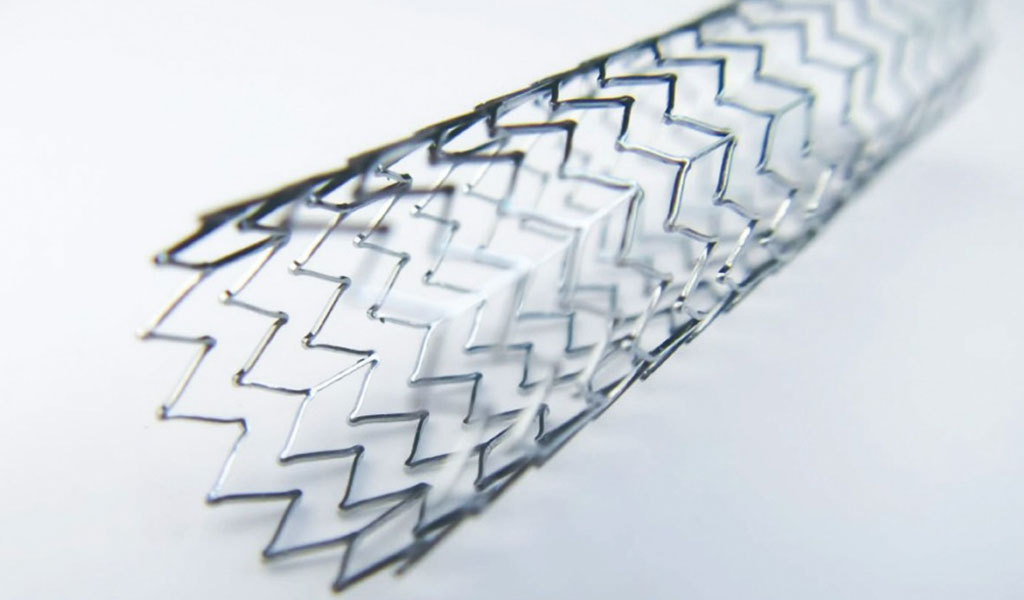

Stents: Nitinol is commonly used in the production of medical stents, which are small mesh-like tubes inserted into blood vessels to treat conditions like coronary artery disease. Laser cutting allows for precise shaping and customization of Nitinol stents.

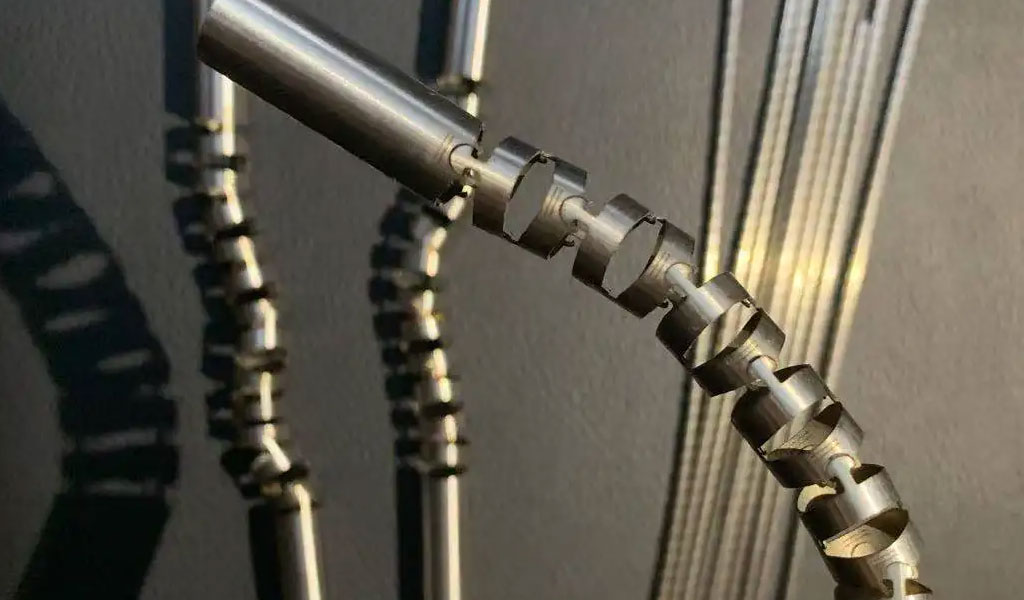

Guidewires: Nitinol guidewires used in medical procedures, such as navigating catheters through blood vessels, can be fabricated with intricate designs through laser cutting.

Nitinol Laser Cutting For Aerospace

Actuators and Mechanisms: Nitinol’s shape memory properties make it suitable for aerospace applications, such as actuators and mechanisms. Laser cutting enables the production of complex shapes and structures for these components.

Nitinol Laser Cutting For Electronics

Micro-Components: Nitinol laser cutting is employed to create tiny components for various electronic devices, including sensors and actuators, where the alloy’s unique properties are beneficial.

Nitinol Laser Cutting For Automotive Industry

Smart Materials: Nitinol can be used in the automotive industry for smart materials, such as adaptive components that respond to changes in temperature or stress. Laser cutting helps achieve the required precision for these applications.

Nitinol Laser Cutting For Consumer Goods

Eyeglass Frames: Nitinol is sometimes used in the manufacturing of eyeglass frames due to its flexibility and shape memory. Laser cutting allows for precise shaping of Nitinol frames.

Nitinol Laser Cutting For Research and Development

Prototyping: In research and development, Nitinol laser cutting is valuable for prototyping various devices and components due to its ability to create intricate designs with high precision.

Nitinol Laser Cutting For Textile Industry

Cutting and Shaping: Nitinol laser cutting can be utilized in the textile industry for cutting and shaping certain fabric components, where precision and unique shapes are required.

Nitinol Laser Cutting For Energy Harvesting Devices

Micro-Generators: Nitinol is explored for use in micro-generators that can convert mechanical energy into electrical energy. Laser cutting is crucial for creating precise components in these devices.

Laser cutting of Nitinol offers a high level of precision and control, making it suitable for applications where intricate shapes and fine details are required. The unique properties of Nitinol, combined with laser cutting technology, contribute to advancements in various industries.

Contact Be-Cu To Get Nitinol Laser Cutting Service today

If you’re looking for the best Nitinol Laser Cut, look no further than Be-Cu.

The highly skilled team at Be-Cu.com provides a variety of micro laser cutting techniques for nickel-titanium at our well-equipped 12,500-square-foot facility in China.

Contact us by [email protected] today to learn more about our Nitinol Laser Cutting services or to request a quote.