Picosecond Laser Cutting

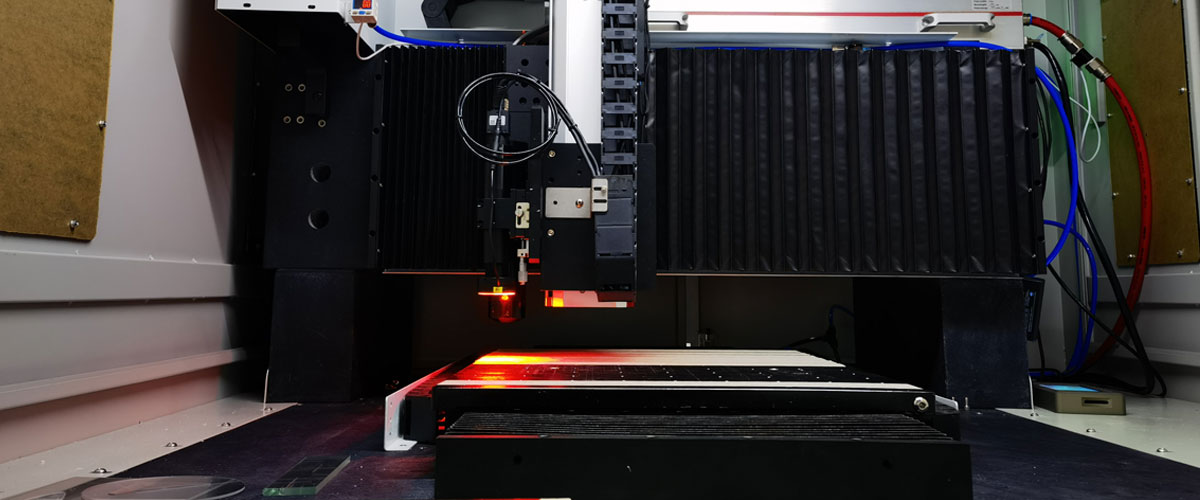

Picosecond laser is a laser with a pulse width of picoseconds. As typical representative of ultra-short pulse laser, picosecond laser has the characteristics of ultra-short pulse width, adjustable repetition frequency, and ultra-high peak power.In the laser cut process, the physical basis for cutting is the interaction between the laser beam and cut material. When the laser irradiates or scans the material, the material absorbs the laser energy and converts it into heat energy. Different energy densities and powers will produce different thermal effects when acting on the material, so different cutting effects can be achieved.

The principle of picosecond laser machining is that when the laser irradiates the surface of the material, except for part of the light that is reflected, the rest of the light energy basically enters the inside of the material, part of which is absorbed by the material itself, and the other part passes through the material. For metals material, the energy of the picosecond laser is linearly absorbed by the free electrons in the material, and plasma is generated after excitation. Under the combined action of the plasma and the picosecond laser, the material expands and explodes internally to generate a shock wave, causing the material in the affected area to separate from the base material. Complete the material processing process.

Top-Tier Picosecond Laser Cutting Company – a Laser Trend on the Rise

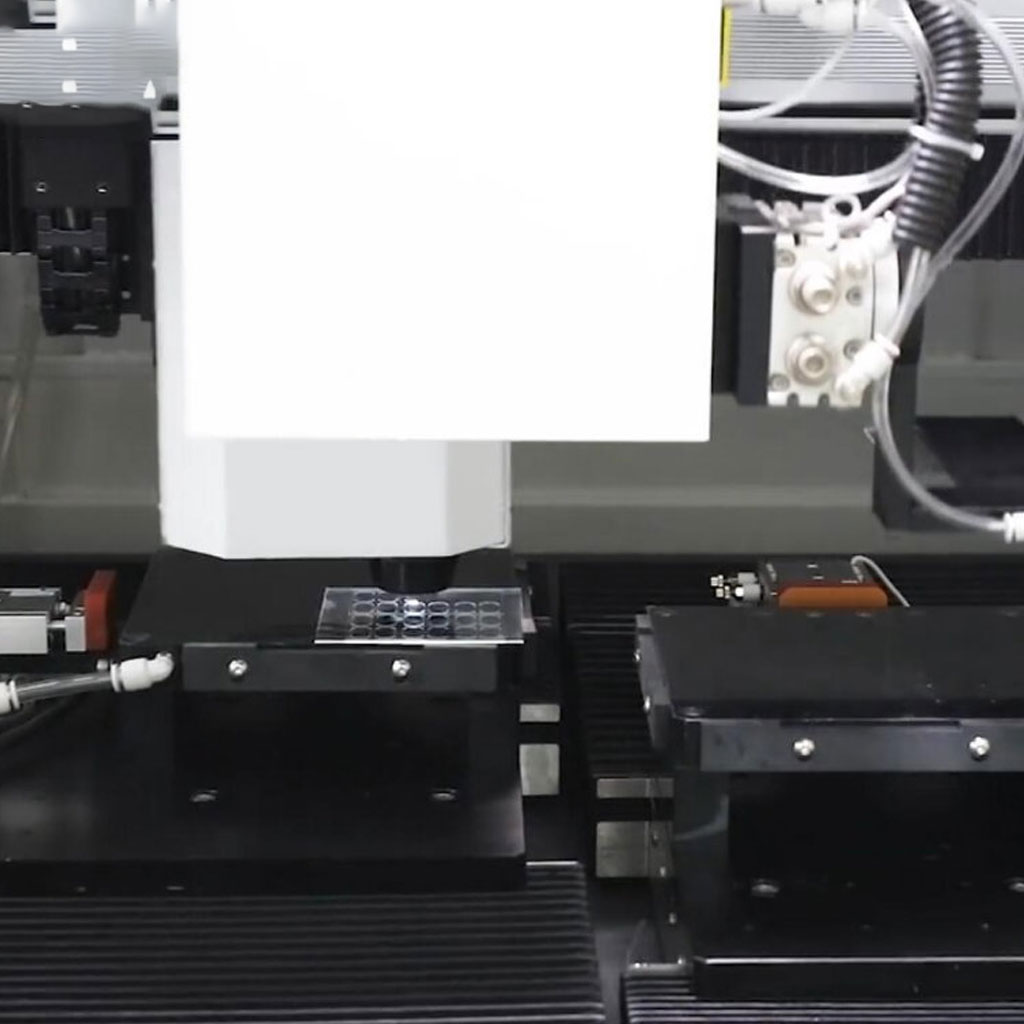

With the rise in computer capabilities, telecommunications and the internet, the demand for picosecond laser cutting services is growing in popularity across the world, with the semiconductor and pcb industry taking a special interest. If the device is not shrinking in size, the components making it work are continuously becoming smaller for better performance and higher efficiency.

Picosecond laser cutting pushes the limits of precision and size. Using extremely precise tools, tight tolerances, and machines that specialize in this area, allows the manufacturing of intricate micro components used most notably in the medical,semiconductor,pcb and electronics industry. Some of the process we use picosecond laser cutting for include:

- Punch Holes

- Cutting

- Forming

- Structure

- Ablation

- Micromachining

Most features of picosecond laser cutting parts are not visible to the naked eye without magnification, thus requiring the use of very high-resolution inspection equipment.

Advancements in the medical, fiber optic and satellite industries are requiring picosecond laser cutting companies across the world to improve their capabilities in precision.Be-Cu prototype is ahead of the industry trend, offering ultra-precision micro manufacturing services for the last three decades.Our picosecond laser cutter are designed to meet demands for extremely small, high-precision workpieces, it’s the ideal choice for a broad range of micro workpieces requiring quality, precision, and efficiency.

The Features Of Picosecond Laser Cutting

Impressive advances in picosecond laser technology have made it a reliable tool for industrial micromachining that was previously impossible to accomplish using other methods. The picosecond pulse width is comparable to the electro-optical relaxation time and is short enough to “cold” ablate the material.

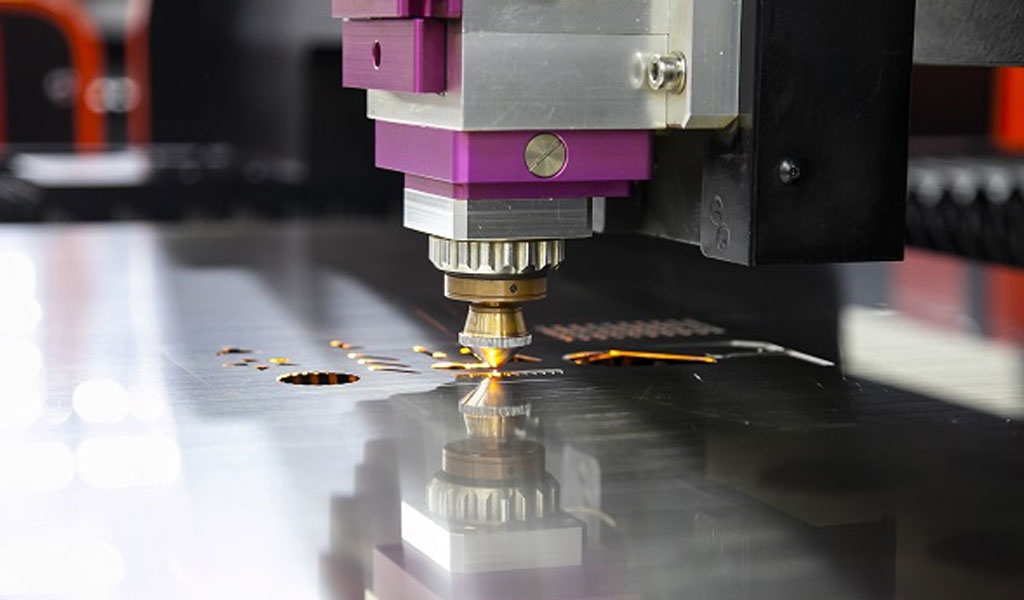

Picosecond lasers also have many advantages over femtosecond lasers with shorter pulse widths. Since there is no need to broaden and compress the pulse for amplification, the design of picosecond lasers is less complex, making them more cost-effective and more reliable. At the same time, the picosecond pulses are still short enough to handle very precise and stress-free micromachining.Compared with nanosecond laser equipment, picosecond laser equipment has a significantly smaller relative heat-affected area, which is more conducive to precision processing; the processing surface is smoother; in addition to circuit board processing, picosecond equipment can also process ceramics, silicon wafers, and iron Fluoron and other materials.

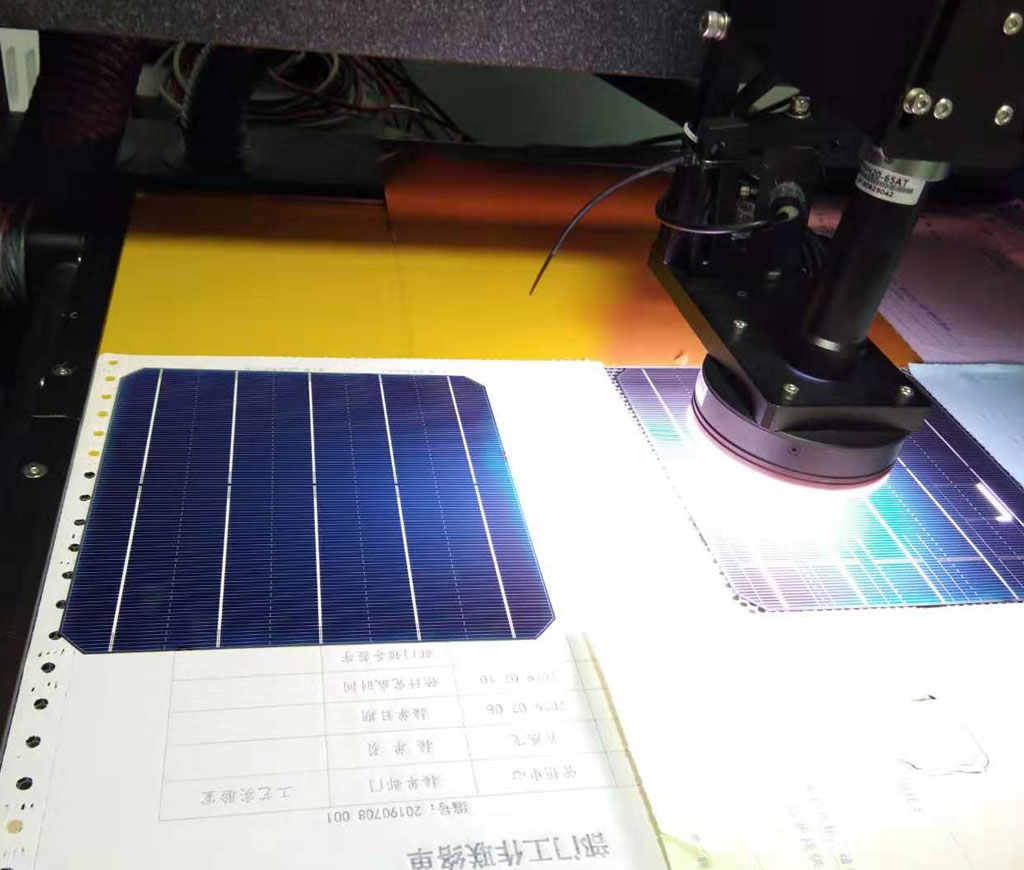

The Application Scope Of Picosecond Laser Cutting

UV picosecond laser cutting machine is suitable for ultra-thin metal materials (copper, gold, silver, aluminum, titanium, nickel, stainless steel, molybdenum, etc.), flexible materials (PET, Pl, PP, PVc, Teflon, electromagnetic film, glue membrane, etc.), graphene, carbon fiber, silicon wafer, ceramic, FPC and other materials, cutting, drilling, surface microstructure (bionic structure), scribing, groove processing, as well as micro-machining of polymer materials and composite materials. The equipment has a wide range of uses and extremely wide applicability. It can realize micro-machining of the surface of various types of materials. It can customize the depth and width to control the surface of the material, such as stripping, etching, etching, scribing, drilling, and cutting.

If other Picosecond Laser Cutting shops cannot handle your micro laser machining needs, give Be-Cu a call. Our high level of experience paired with highly accurate micro laser cutter make Be-Cu uniquely qualified to achieve what normal laser cut shops find impossible. To manufacture complex components with the highest accuracy, we use femtosecond laser cutting, Wire EDM machines (capable of achieving micron positional accuracies), 5-Axis Machining Centers and as required, the tools/plunge patterns for our in-house EDM Sink operations.

Contact our micro manufacturing professionals today to learn more about our services and capabilities.

Certifications & Quality Cutting

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

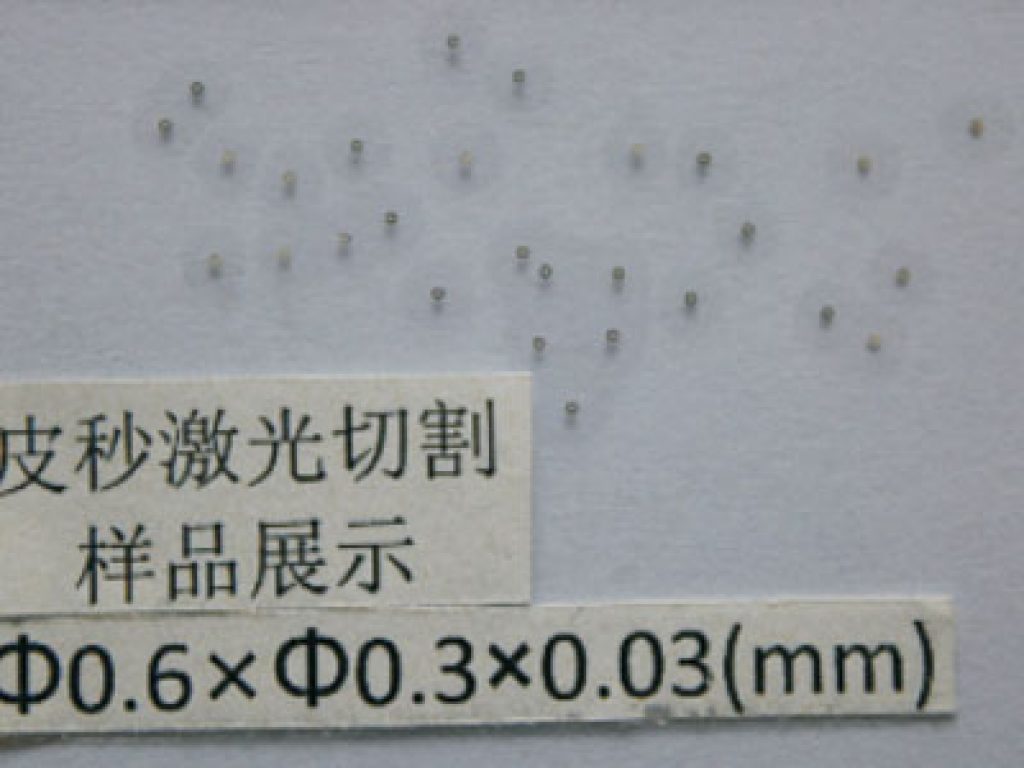

Top China Leading Picosecond Laser Cutting Case Studies

With Be-Cu’s state-of-the-art technology and laser cutting equipment, we can oversee our laser process with a full 3-D visualization, making our process fast, smooth, and efficient. For example, when laser cutting a cogwheel for a watch manufacturing client, it only takes Be-Cu about 30 seconds to complete the precision cutting. Precision is the key to such small and intricate components, where the functionality of the product depends on it.Couldn’t find the case studies you want? Contact us now, we have a strong in-housing supply chain, can Picosecond Laser Cutting any prototype project and parts for you.

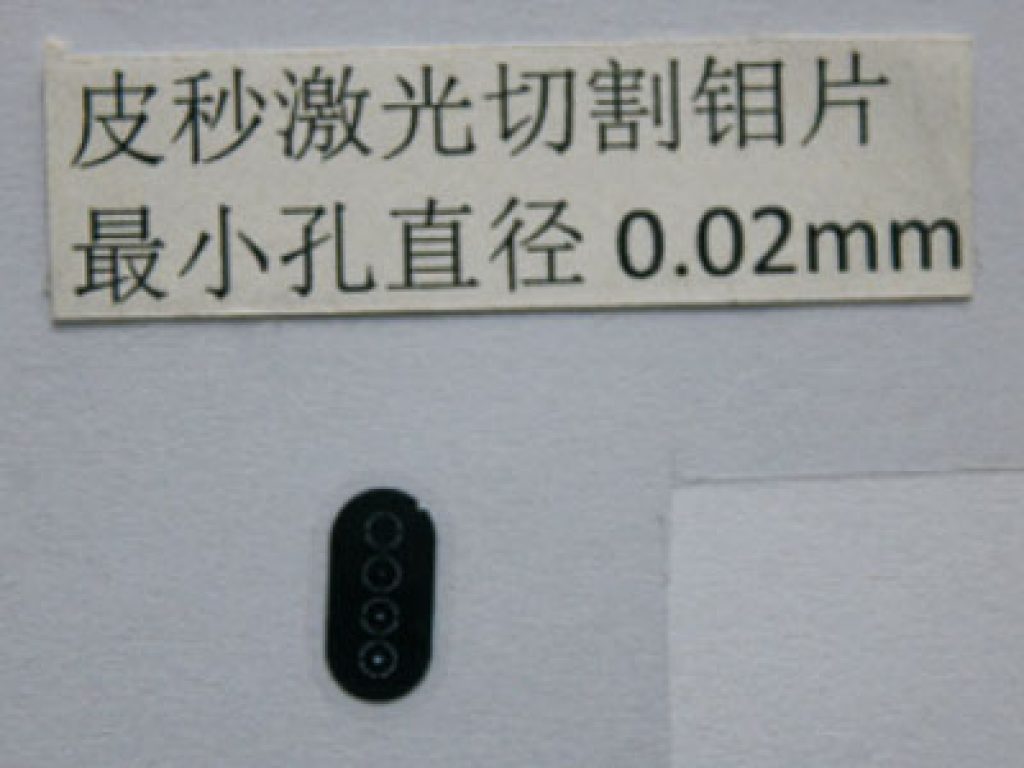

0.02mm Picosecond Cut Molybdenum

Laser Cutting Preformed Welding Sheet

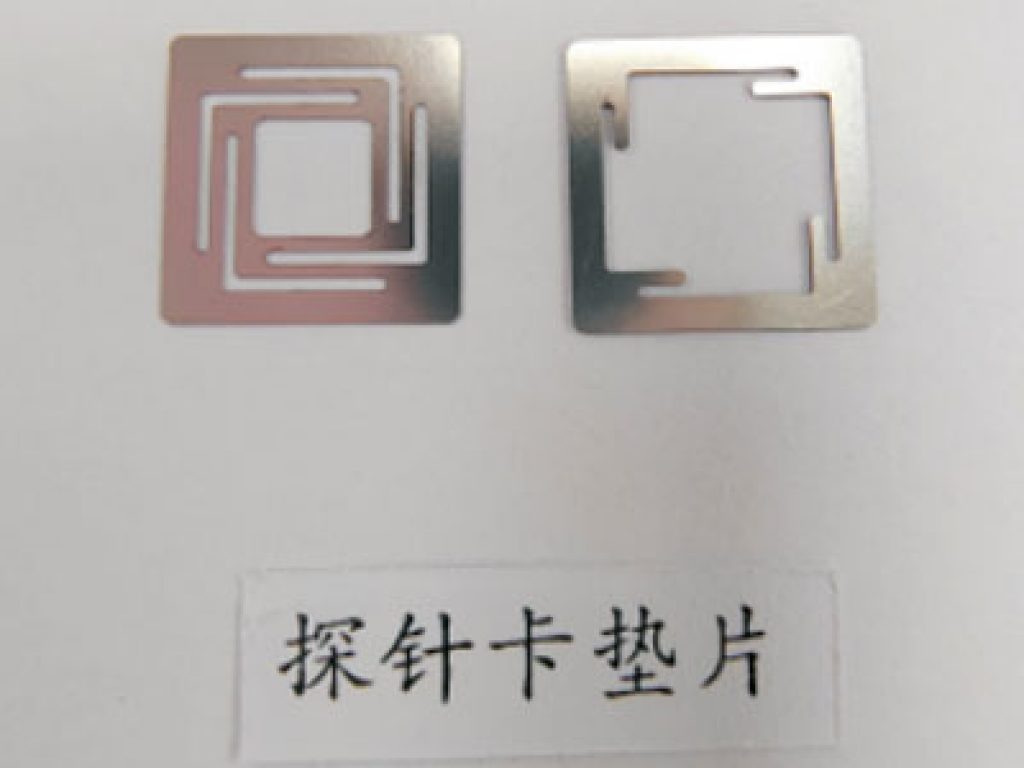

Laser Cutting Probe Card Spacer

Picosecond Laser Cutting Camera

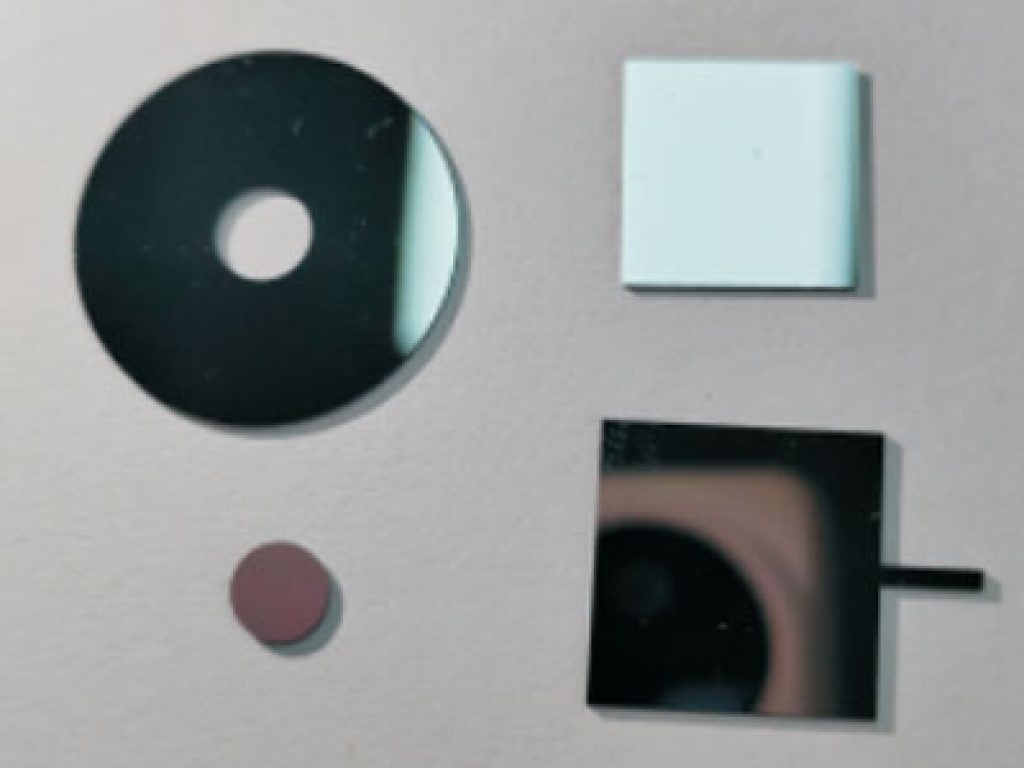

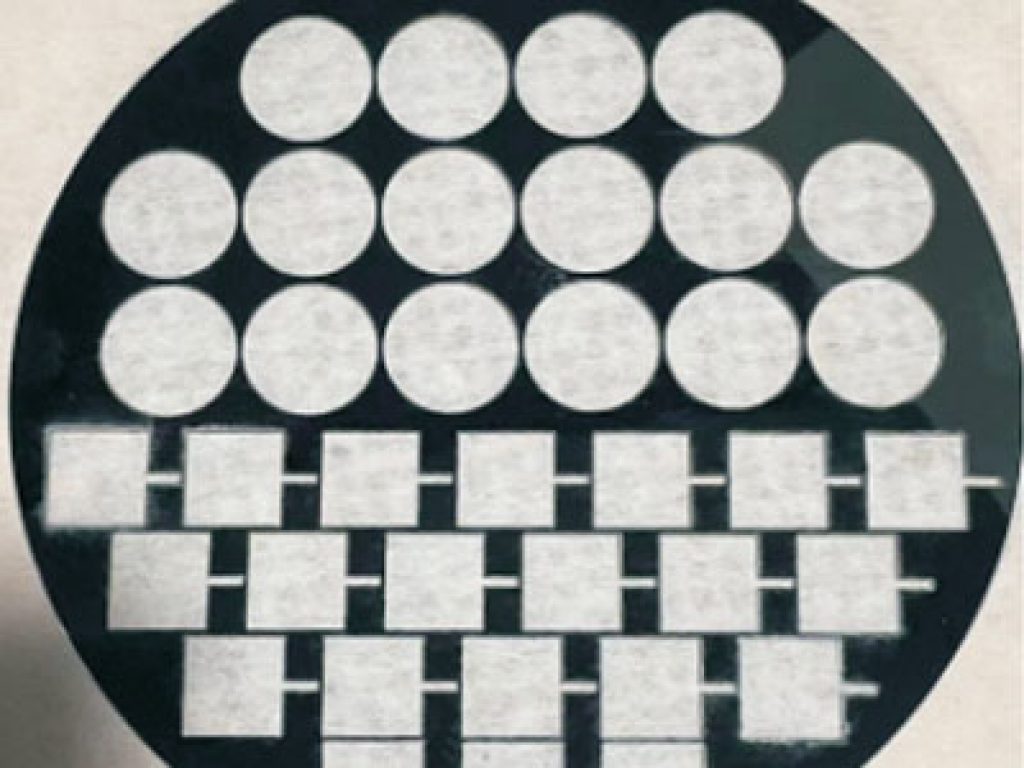

Silicon Wafer 2

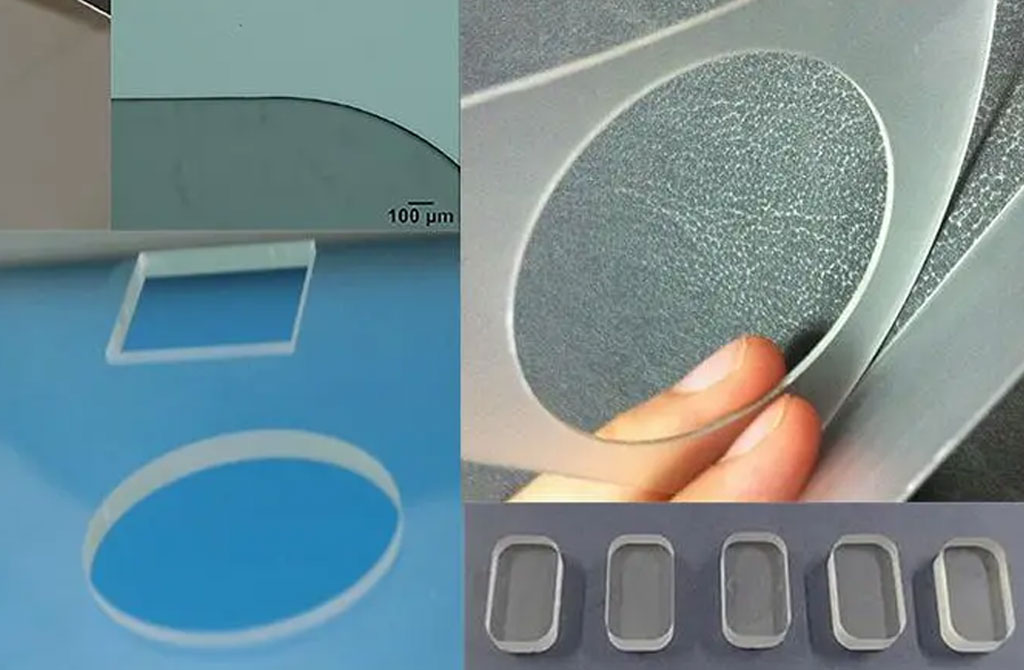

Silicon Wafer

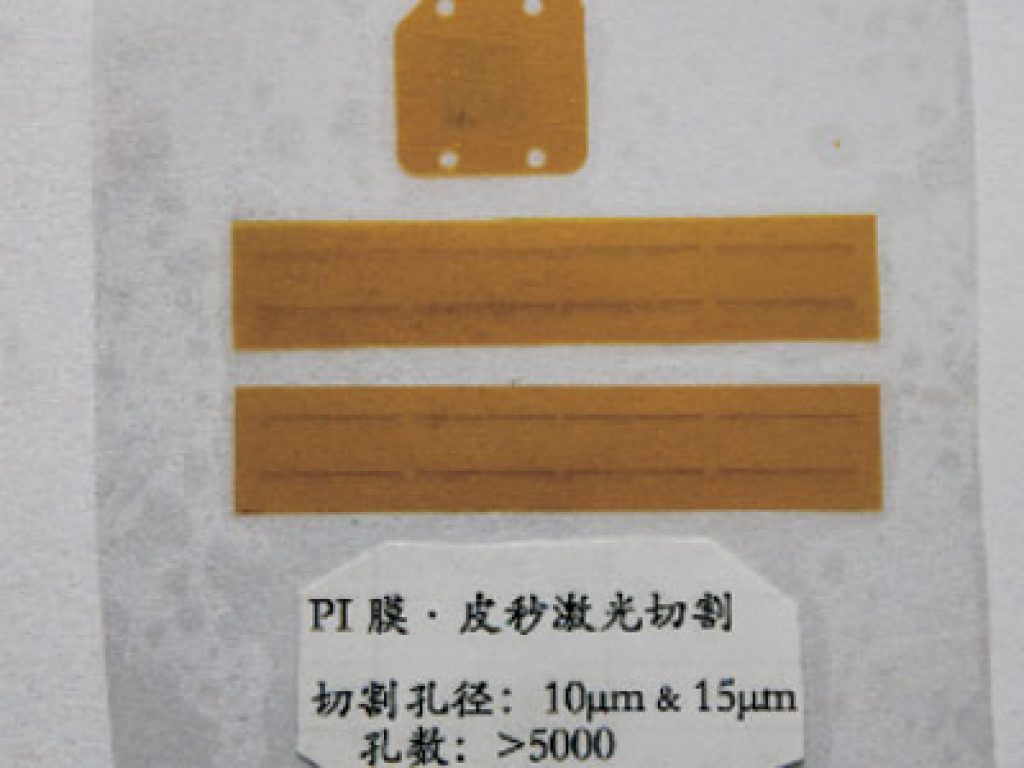

PI Film 1

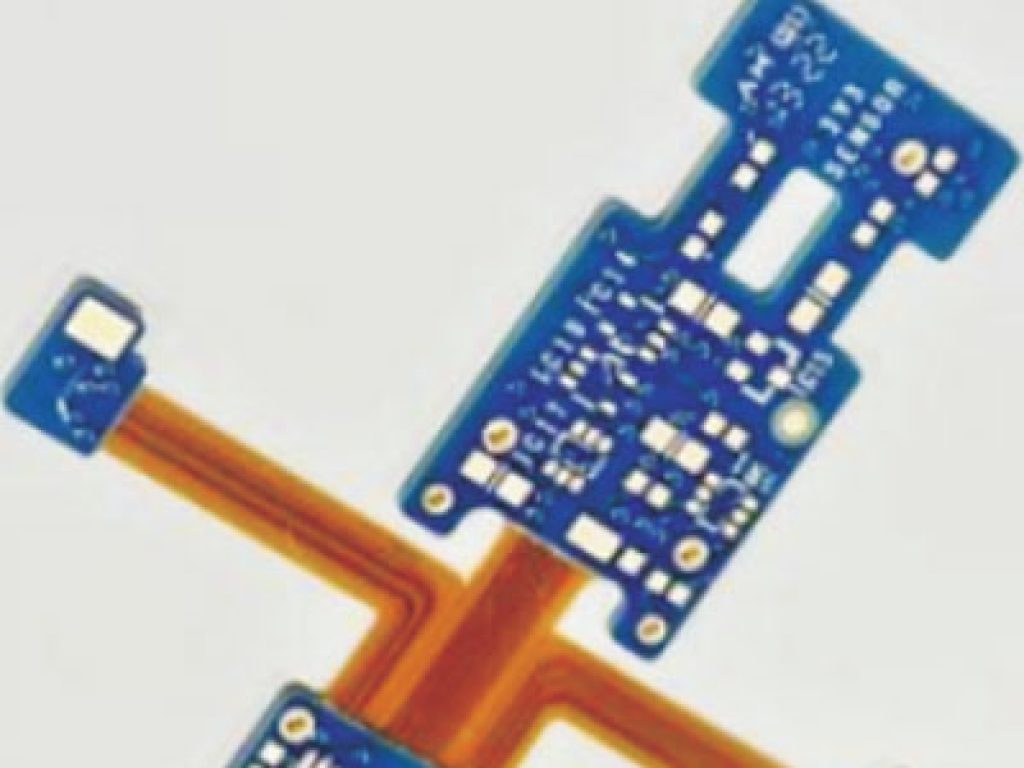

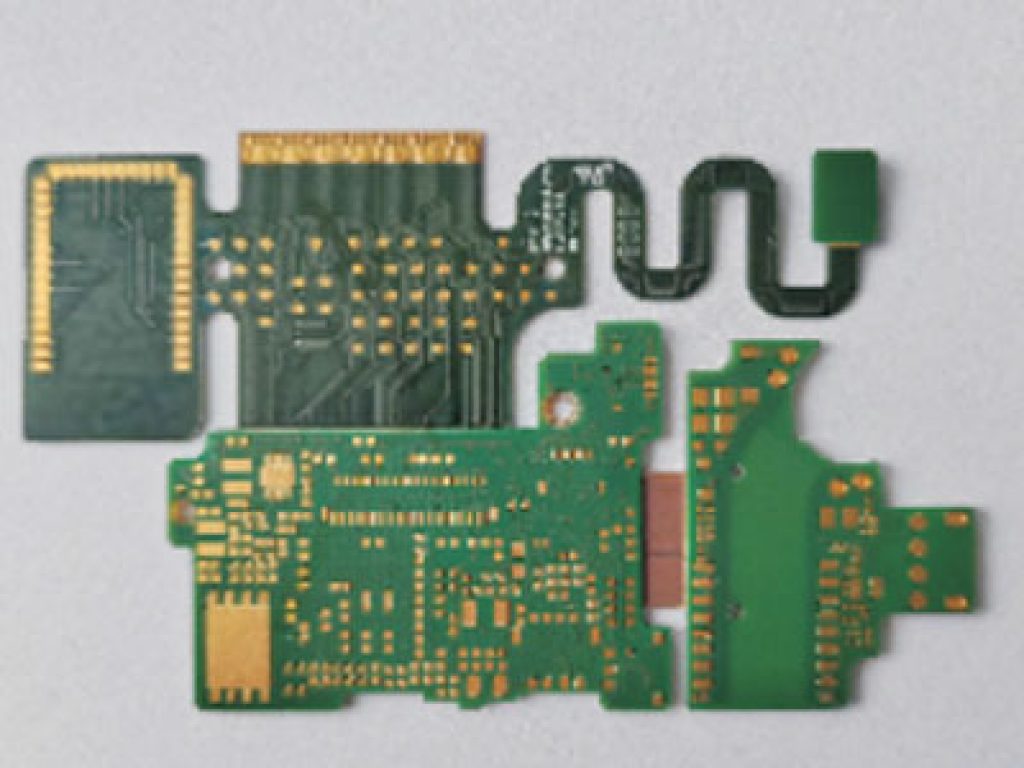

PCB Cut 4

PCB Cut 3

PCB Cut 2

PCB Cut 1

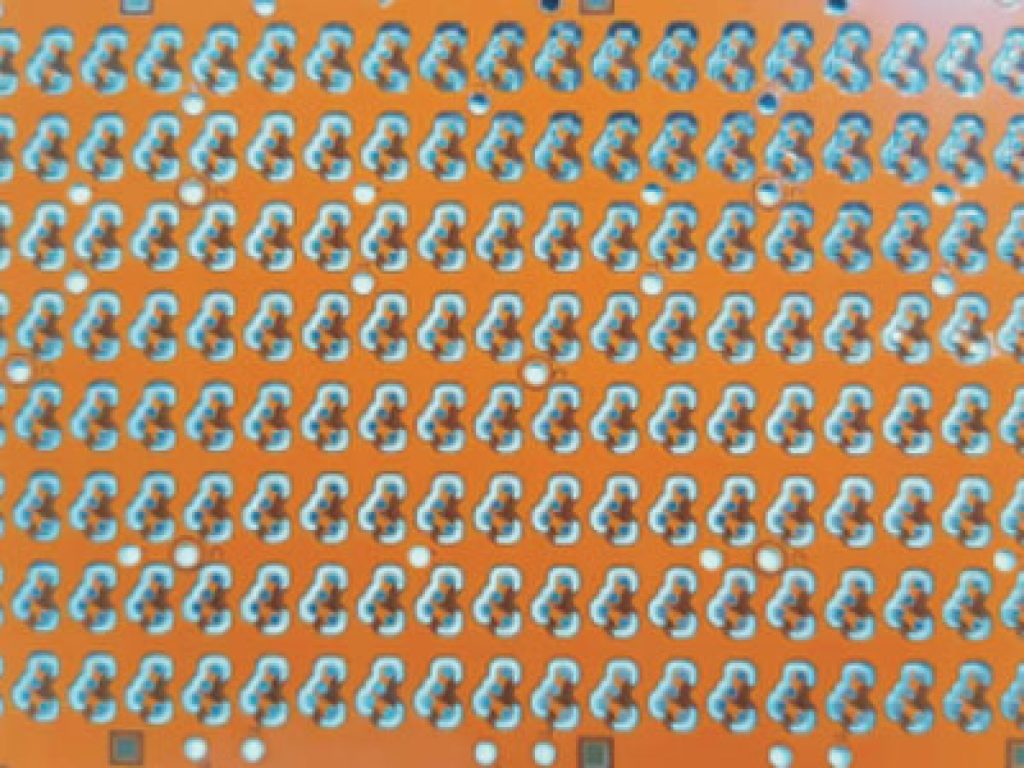

9-μm Microporous Sheet

9-μm 7075 Microporous Sheet

5-μm 304 Microporous Sheet

0.6mm 304 Microporous Sheet

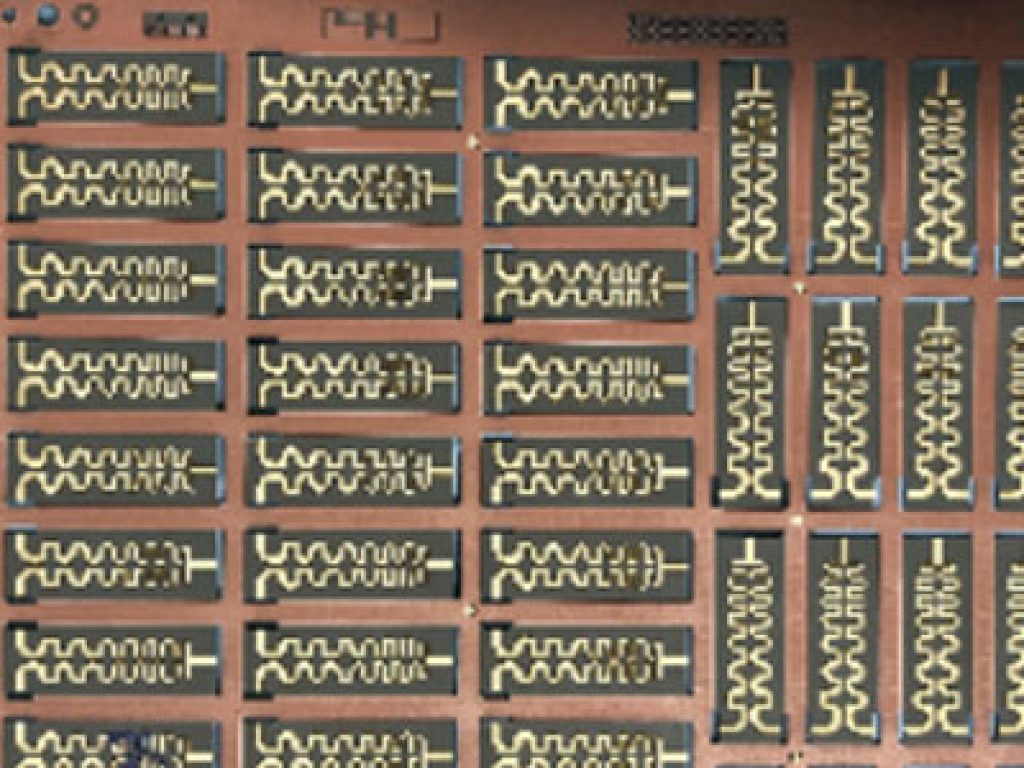

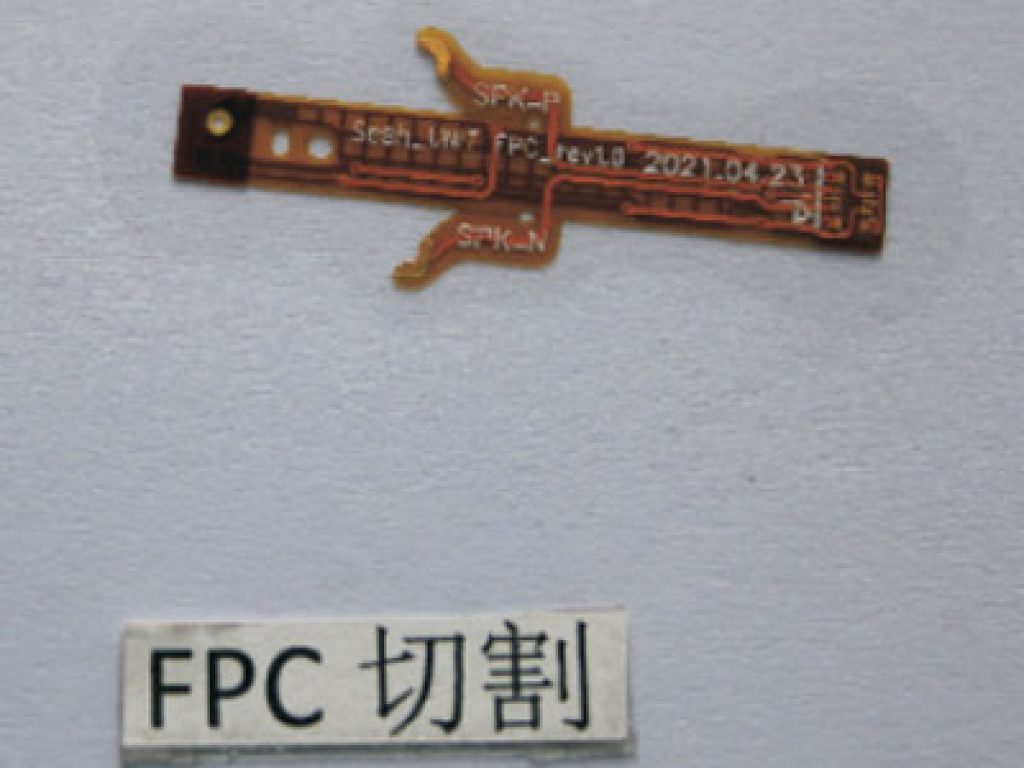

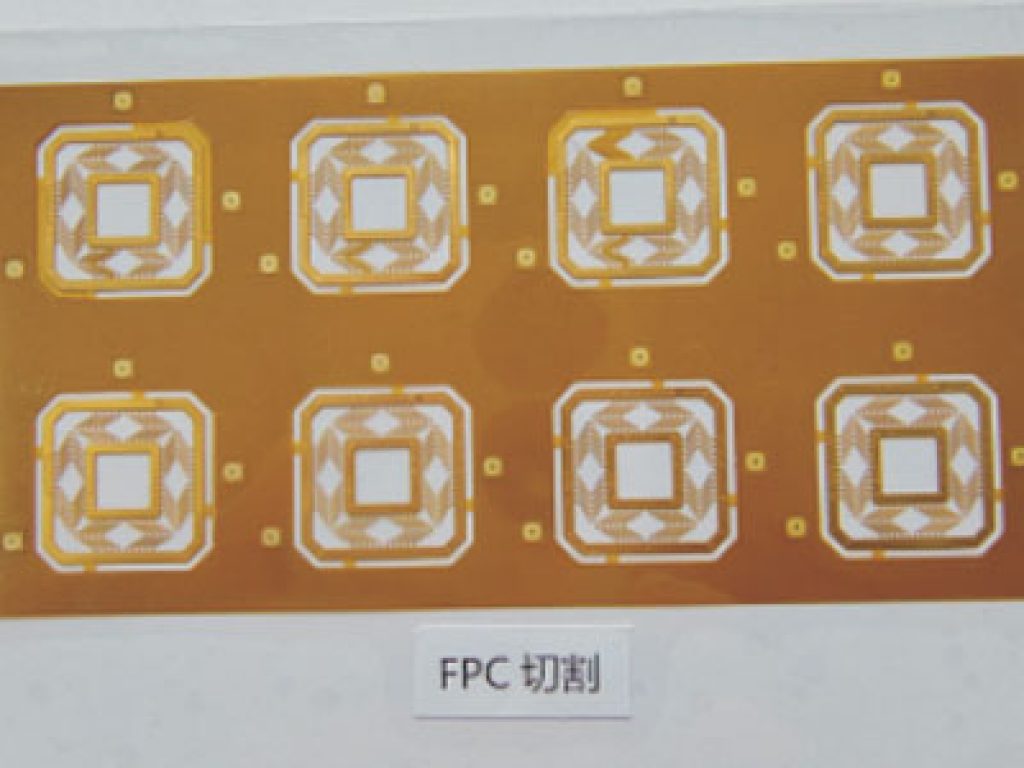

FPC Cut 4

FPC Cut 3

FPC Cut 2

FPC Cut 1

10μm PI Film

Online Cooperate With Picosecond Laser Cutting Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision Picosecond Laser Cutting capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.