What Is Micro Laser Cutting

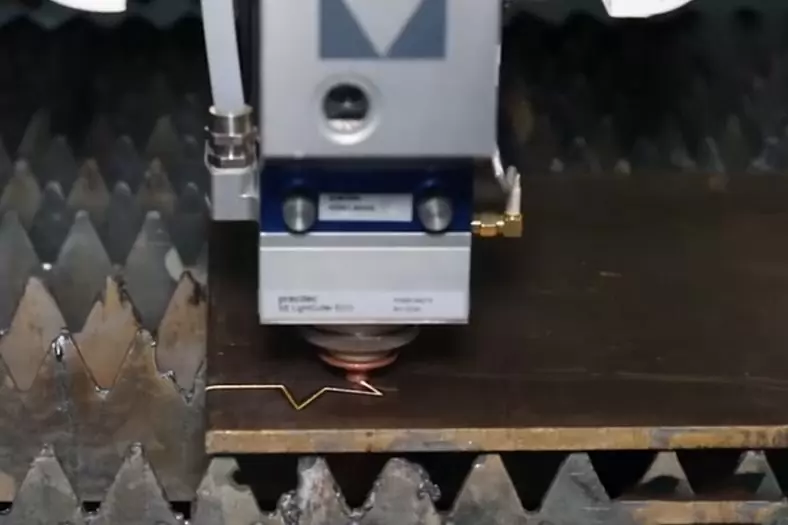

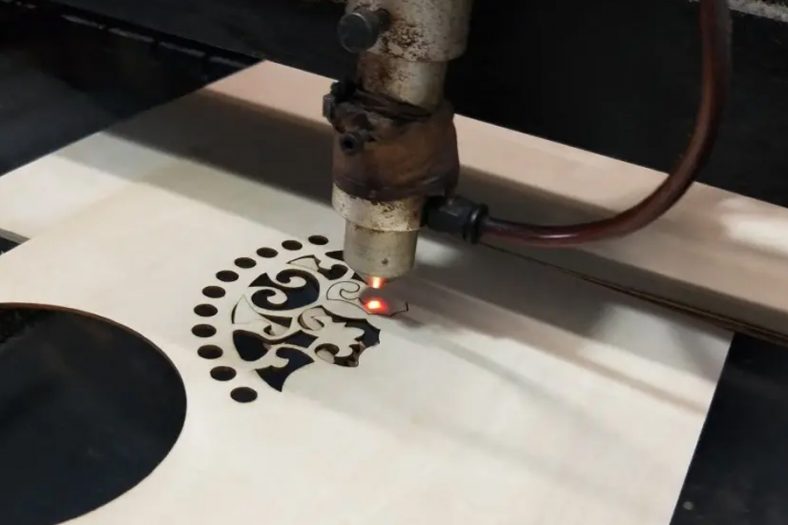

Micro laser cutting is a precise manufacturing process that uses a focused laser beam to cut extremely small and intricate patterns or shapes on various materials with high accuracy. This technology enables the cutting of materials at a micron level, allowing for intricate designs, tight tolerances, and minimal heat-affected zones.

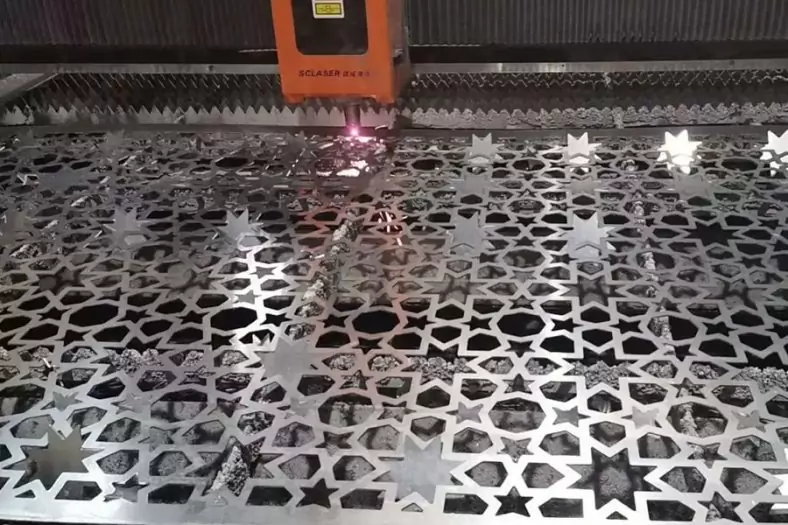

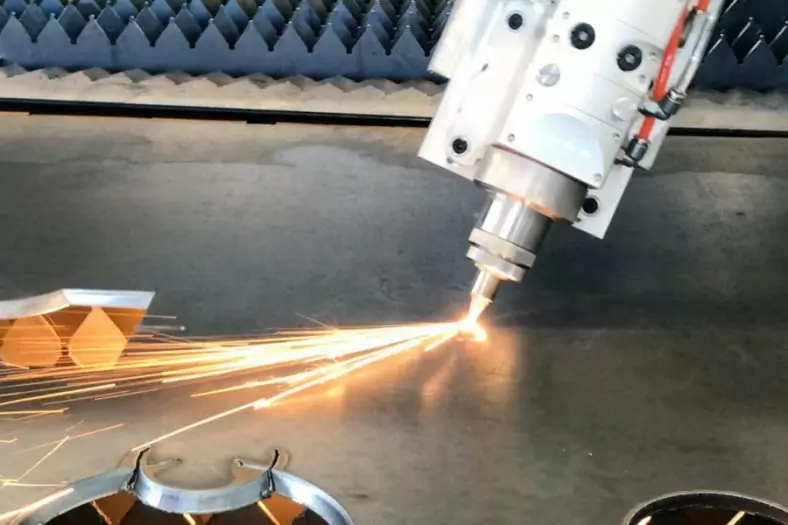

The process involves the use of a focused laser beam, typically a CO2 or solid-state laser, directed onto the material surface. The intense heat generated by the laser beam melts, burns, or vaporizes the material along the desired cutting path. The beam is controlled by computer numerical control (CNC) systems, which precisely guide the laser according to the pre-programmed design.

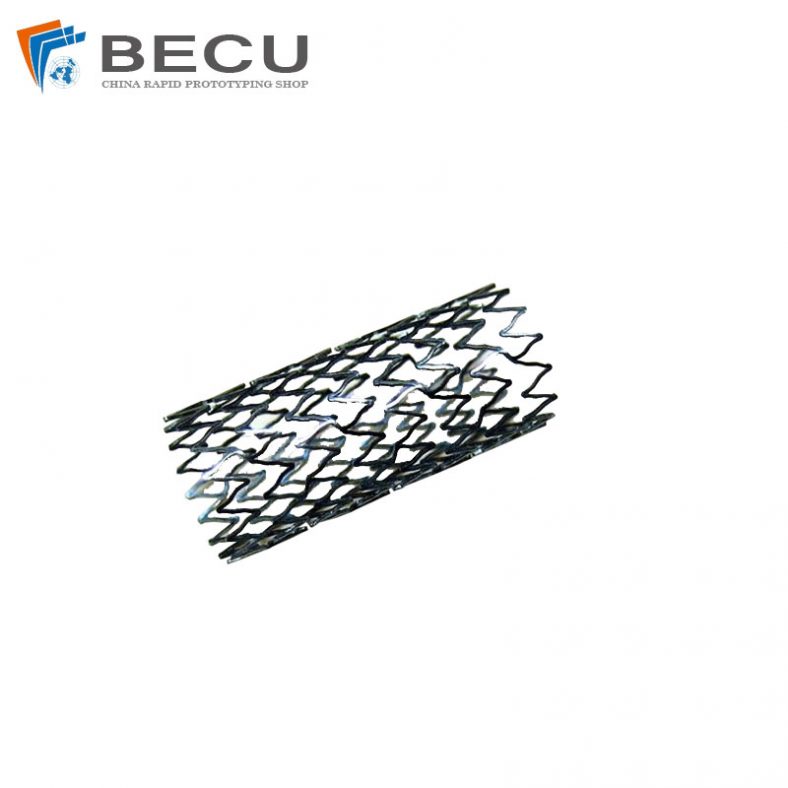

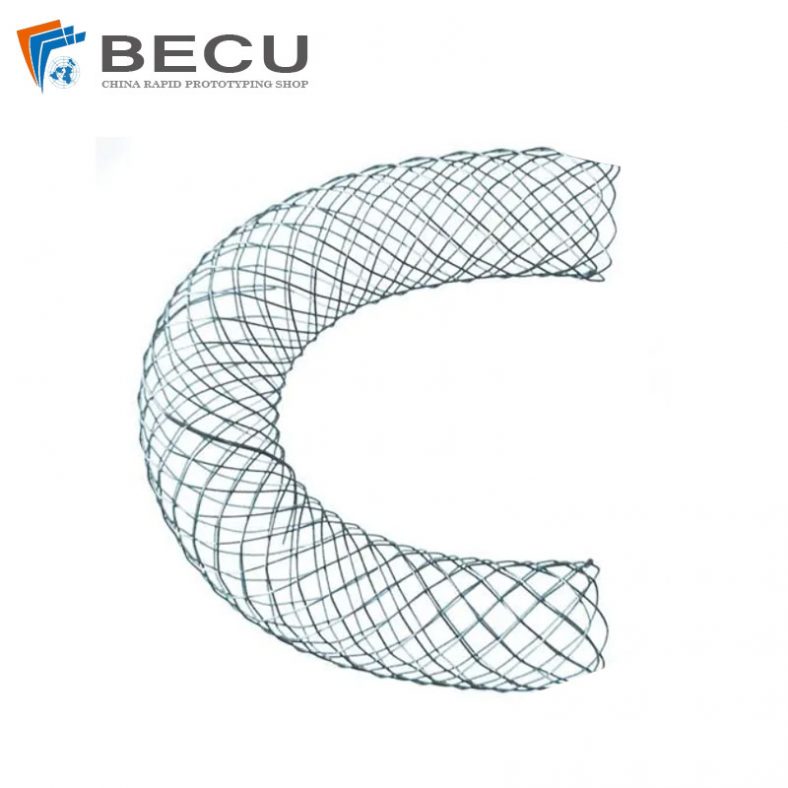

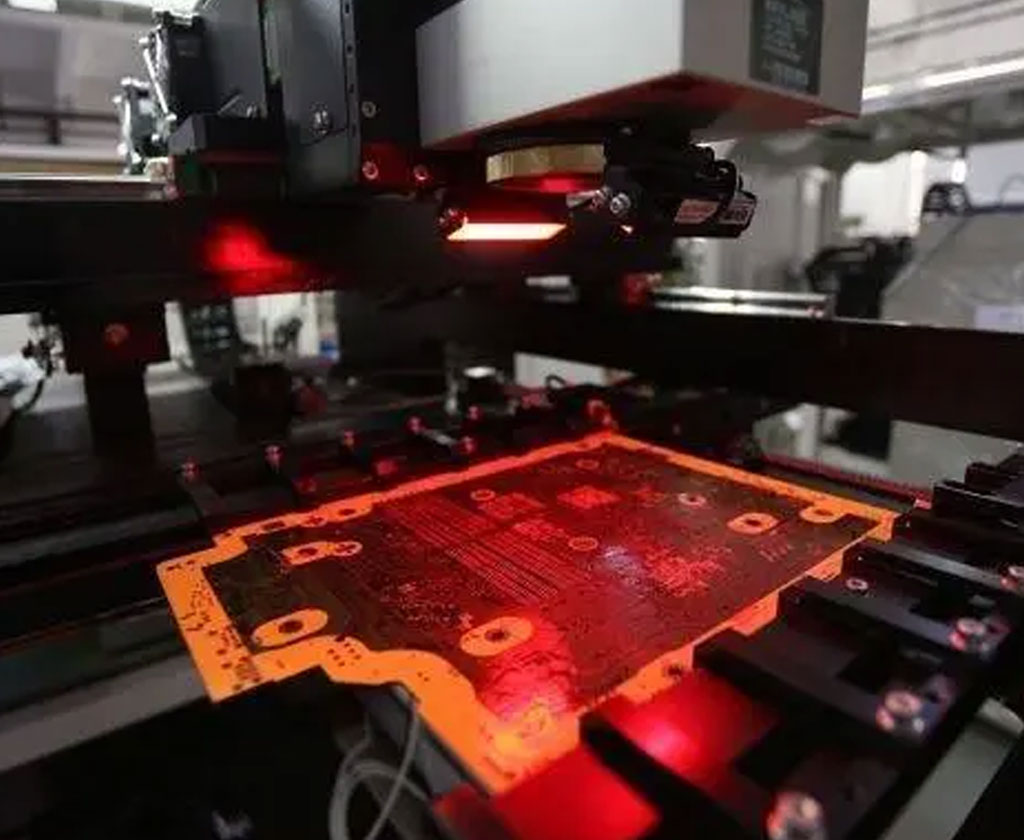

Micro laser cutting finds applications in various industries, including electronics, medical devices, aerospace, automotive, and microfluidics. It is used to create small components, micro-parts, stents, sensors, micro-electromechanical systems (MEMS), and intricate patterns on materials like metals, plastics, ceramics, glass, and thin films.

The advantages of micro laser cutting include high precision, minimal material distortion, the ability to create complex geometries, and the absence of direct physical contact between the cutting tool and the material, reducing the risk of contamination or damage.

Precision Micro Laser Cutting Service & Miniature Parts Cut

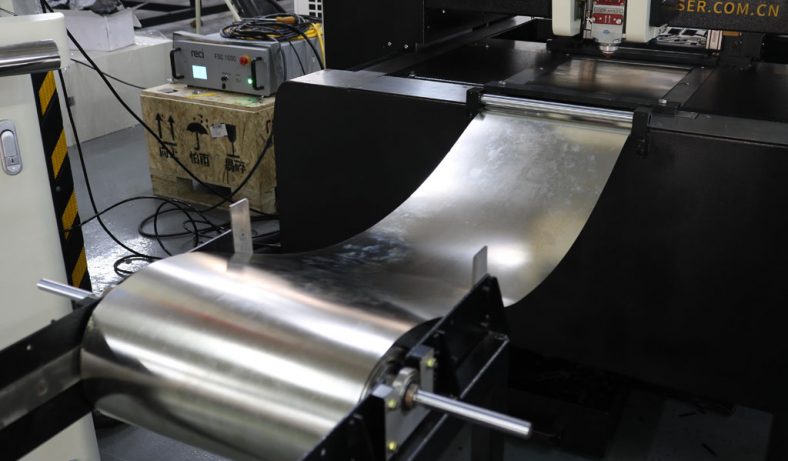

Micro laser cutting pushes the limits of precision and size.Micro laser cutting is a powerful tool for crafting exact, tiny plate and pipe.These pipe or plate can be cut down to one-thousandth of a millimeter, helping make the production of tiny parts more efficient and realistic.

Advancements in the medical, fiber optic and satellite industries are requiring micro laser cutting companies across the world to improve their capabilities in precision. Be-Cu prototype inc is ahead of the industry trend, offering ultra-precision micro laser cut services for the last three decades. Our micro laser cutter are capable of cutting with tools smaller than the diameter of a human hair. Utilizing our vast knowledge of Micro laser cut techniques and decades of industry experience, we are confident that we can produce your most challenging components to your exact specifications. To learn more about how BE-CU can help you with your next micro laser cutting project, contact our manufacturing team with your request for a precision micro laser cutting services quote.

Our Micro Laser Cutting Specification

- Minumum Width Of Cut:Typically 5µm

- Maximum Material Thickness:Typically 1mm (dependant on speed requirements)

- Material:Most materials from Metal to hard ceramics including transparent materials

Our Micro Laser Cutting Industries

- Medical Laser Cutting

- Electronic Laser Cutting

- Aerospace Laser Cutting

- Optics Laser Cutting

Engineers, innovators, maintenance managers and others choose Be-Cu for custom micro Laser cutting, because we are able to effectively and accurately metal fabrication, with absolutely no minimum orders. At Be-Cu.com, you don’t have to worry about dealing with a laser cutting shop queue, or your small-quantity order being bumped for a production run.We pride ourselves on our reliability and superior customer service. Contact us to get started.

Micro Laser Cut Parts and Components for Every Industry

Numerous industries are eagerly following the trend of utilizing miniature parts in their product applications – including electronic tooling, medical parts, component energy-driven motors, fluidic circuits and particle filters just to name a few. The extreme attention to detail, dedication to precision and high level of expertise garnered in our employees is what sets BE-CU apart from other laser cutting shops, making our reputable services highly sought after across a multitude of industries, including:

Certifications & Quality Cutting

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Metal Material Of Micro Laser Cutting

Metal material can be easily machined and have a low raw material cost, making them often the most economical choice for prototyping and Micro laser cutting.There are a few factors to consider when choosing the right metal for Micro Laser Cutting. The metal you choose is critical to your ultimate success. For example, metals may need to withstand high temperatures or bend or break under pressure. When choosing the right metal, corrosion resistance, machinability, price, weight and visual appearance all play a role.

Top China Pipe/Plate/Sheet Micro Laser Cutting Case Studies

Laser cutting processes such as fiber laser cutting , Co2 laser cutting and Micro laser cutting are today considered the most economic way to make metal prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sheet metal is the only option. Our company has rich experience making metal concept models and precise functional components. Understanding the properties of different metal material, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on metal material. Be-cu prototyping company provides a range of solutions for the cutting of Metal Parts.