Metal Spinning Toy

- Material: Brass

- Stamping Size: Custom

- Stamping Type: Spinning Brass

- Stamping Mold: Metal Spinning Molds

- Spinning Thickness: 1.5(mm)

- Post-Processing: Custom

- Surface Treatment: Custom

- Application: Toy

The Mesmerizing Art and Science Behind Metal Spinning Top Toys

Metal spinning top toys have fascinated both children and adults for generations. With their mesmerizing spinning motion and elegant design, these toys have captured our imagination and provided endless hours of joy and entertainment.

The History of Metal Spinning Tops

Metal spinning tops have a rich history that dates back thousands of years. Archaeological evidence suggests that spinning tops were used in ancient civilizations, including ancient Egypt and Greece. Over time, the design and materials of spinning tops have evolved, with metal tops becoming popular due to their durability and longevity. In the 19th and 20th centuries, metal spinning tops gained further popularity, becoming cherished playthings and collectibles.

The Manufacturing Process of Metal Spinning Tops

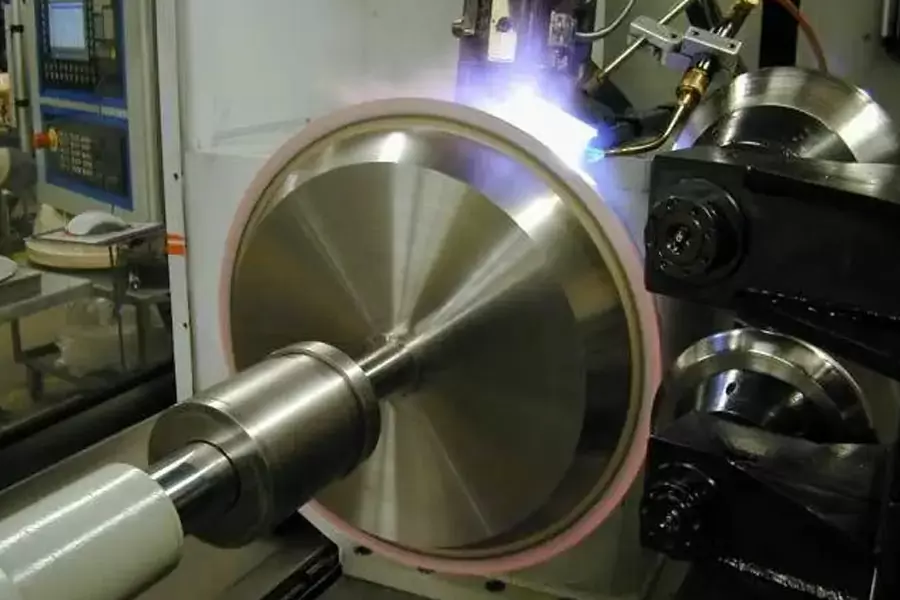

Creating metal spinning tops involves a fascinating manufacturing process that combines craftsmanship and modern techniques. The process typically starts with selecting the appropriate metal, such as aluminum, brass, or stainless steel. The metal is then shaped into a disc or cone-like form using techniques like CNC machining or metal spinning.

Metal spinning, also known as spin forming or metal turning, is a specialized technique where a metal disc is clamped onto a spinning lathe and manipulated by skilled craftsmen. With the application of carefully controlled force and precision tools, the metal is gradually formed into the desired shape, often with a pointed tip for balance and stability during spinning.

The Physics of Spinning Tops

The physics behind the spinning motion of tops is a fascinating subject. When a spinning top is set into motion, several principles come into play. One of the key factors is rotational inertia, which relates to the distribution of mass around the spinning axis. Tops with a higher rotational inertia tend to spin for longer durations.

Additionally, the phenomenon of precession plays a significant role. Precession refers to the gradual change in the orientation of the spinning top’s axis of rotation. This motion arises due to the interaction between the spinning top and external forces, such as gravity and friction. The precession of spinning tops creates a beautiful dance as the top gracefully moves around its central axis.

Design and Innovation in Metal Spinning Tops

Metal spinning tops offer a canvas for creativity and innovation. Artists and designers have pushed the boundaries of top design, exploring unique shapes, materials, and surface finishes. Intricate engravings, colorful anodized coatings, and precision machined details elevate spinning tops from mere toys to objects of art.

In recent years, there has been a resurgence of interest in spinning tops as collectibles and high-end executive toys. Collectors appreciate the craftsmanship, limited editions, and the tactile pleasure of spinning these exquisite objects. Some artisans even incorporate rare materials, such as titanium or exotic woods, to create one-of-a-kind spinning tops that are as visually stunning as they are functional.Be-Cu spun factory has 20+ experience spinning brass parts for companies like Top Toy Brand. Our team of highly skilled spinners offer 30+ years of combined expertise.Do you have a big idea that our spinners can help with? Contact us today for a free estimate and get free friendly help and advice from a member of the team.

The Enduring Appeal of Metal Spinning Tops

Metal spinning tops have an enduring appeal that transcends generations. They offer a break from the fast-paced digital world, allowing us to reconnect with tactile experiences and the simple joy of play. Spinning tops are also a source of wonder and fascination, engaging our senses and captivating us with their graceful motion.

Metal spinning tops embody a perfect blend of artistry, craftsmanship, and scientific principles. From their ancient origins to modern-day iterations, these toys continue to enchant people of all ages. Whether it’s the thrill of watching them spin, the intricate designs, or the calming effect they have on our minds, spinning tops hold a timeless charm.

Why Choose Our Metal Spinning Top Toy Service?

- Tooling. Metal spinning of exotic or super alloys does require tooling, however the tooling in most cases will last for the lifetime of the product. Be-cu.com’s experience in spin tool development allows optimized tooling, such that thinning, follow on trimming and material spring back are controlled.

- Prototyping. Because tooling is minimized metal spinning can be a good fit for prototyping of complex components. As the design concept evolves tooling may be adjusted to match the part and quickly produce more prototypes.

- Cost. Given a suitable geometry Metal Spinning can be a very cost effect way to produce large diameter hollow shapes.

Contact Be Cu Now for your Custom Metal Spinning, We are your best online Spinning services choice!

The Advantage of Metal Spinning Top Toy

- Compared to the tools employed in alternative forming methods, metal spinning tools are typically 10% of the cost.

- The metal spinning process amounts to significantly shorter turnaround times – tools and spun components can be available within weeks rather than months.

- Metal spinning tools can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Metal spinning produces smooth, durable objects without seams or welds, for parts require feature superior strength and great aesthetics.

The Specifications of Precision Metal Spinning Top Toy

| CNC Metal Spinning Capabilities | English Units | Metric Units |

|---|---|---|

| Max Part Length / Height | 48.0 in | 1,220 mm |

| Max Blank Size, Diameter | 49.0 in | 1,245 mm |

| Max Roller Force | 19 ton | 169 kN |

| Max Blank Thickness, Stainless Steel | 0.25 in | 6.3 mm |

| Max Blank Thickness, Steel | 0.31 in | 8 mm |

The Shapes Achieved Of Metal Spinning Parts

Simple shapes are easy to make in less time. But for complex shapes, it requires more time because it increases steps as per the block shape.

In addition to metal spinning, Be-cu.com also offers in-house tooling, welding, abrasive polishing and hydroforming, helping to drive down your costs and streamline production. Quicker turnaround times and lower costs are two of the most attractive advantages of metal spinning. The ability to form very thick components and large diameters with uniformity and high quality at low and high quantities, are more appealing reasons to consider metal spinning.To find out if metal spinning would be beneficial for your application or end product, contact us today.

- Domed

- Flanged

- Domed with flange

- Dished

- Semi elliptical

- Hemisphere

- Flanged, dished and flued

- Trumpet

The Detail Of BE-CU Metal Spinning Company

At Be-cu.com, we use a variety of materials for metal spinning such as cold rolled steel, hot rolled steel, aluminum spinning, stainless steel spinning, brass, copper spinning and exotic metals such as titanium and inconel. Be-cu Metal Spinning Section specializes in the forming of stainless steel. With our automated metal spinning lathes and the capabilities of our deep drawing, stamping and welding equipment, our ability to form your part to your specifications and within your budget are realistic. Be-cu Metal Spun Company has over 30 years of metal forming experience and has used the spinning technology for a variety of industries such as aerospace, automotive, military, ordnance, plastics, lighting, pharmaceuticals, dairy, etc…

We have engineers on staff with metal spinning expertise to help guide you on designing a custom part and choose the optimal process to produce high quality spun parts at a competitive and affordable price. Tooling is custom made to form parts to your configuration.