What is Brass Alloy & What is it Used for

Adding zinc to pure copper will make the color of copper yellow, which is brass, so the main components of brass are copper and zinc. Brass has good mechanical properties and wear resistance, and can be used to manufacture precision instruments, ship parts, bullets and shells of artillery shells, etc. Brass sounds good when struck, so musical instruments such as gongs, cymbals, bells, and horns are all made of brass.

Brass is divided into ordinary brass and special brass according to its chemical composition characteristics, and can be divided into processed brass and cast brass according to the production process.

The performance of ordinary brass is related to its zinc content. When the mass fraction of zinc is less than 32%, it has good mechanical properties, is easy to perform various hot and cold processing, and has very good corrosion resistance to the atmosphere and seawater. Ordinary brass is mostly used to make cold deformation parts, such as condensers, cartridge cases, etc.

A small amount of other elements, such as aluminum, iron, silicon, manganese, lead, tin, nickel and other elements, are added to ordinary brass to form special brass. Usually, when a certain metal element is added, it is called a certain brass. For example, nickel-nickel brass and lead brass are brass with nickel and lead added. The addition of these elements can improve the corrosion resistance and wear resistance of the alloy to varying degrees, manganese is used to improve the heat resistance, silicon can improve the casting properties of the alloy, and lead can improve the machinability and lubricity of the material.

Cnc Machining Brass Services – Custom Brass Machined Parts China

Looking for reliable, quick-turn brass cnc machining services suppliers and CNC Machined product manufacturers?

The professionals at BE-CU prototype use a combination of vertical and horizontal CNC machining centers to produce precision components made from brass and its alloy.BE-CU’s facility also includes eight equipment models, with 13 brass milling centers in total. This allows for even more flexibility in manufacturing. Our team of engineers selects the most appropriate equipment to complete CNC machining processes based on several factors, including the volume, material, and geometry of the part produced. In turn, we provide our customers with top-quality products at the most competitive prices.Contact us for a quote for your project, we are dedicated to provide you with quality cnc machining brass parts services.

Why Choose Our Brass Cnc Machining Service?

- Save time and money for your brass project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of brass grades and alloy materials can be machined

- Custom complex brass machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Brass Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make brass prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making brass concept models and precise functional components. Understanding the properties of different brass alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on brass alloy. Be-cu prototyping company provides a range of solutions for the machining of brass parts.

-

Precision Turning H59 Brass Dough Hooks And Beaters

-

Brass Direct Injection Flame Distributor Nozzle For Gas Stove

-

CNC Machining Brass Natural Gas Kitchen Appliance Valve Core

-

CNC Machining Double Threaded Pen Nib

-

CNC Machining Brass Solid Gourd Keychain

-

Precision Turning Solid Wenchang Pagoda Copper Ornament

-

Turn-Mill Machining Electronic Connector Components

-

Brass Turning Welding Machine Plug

-

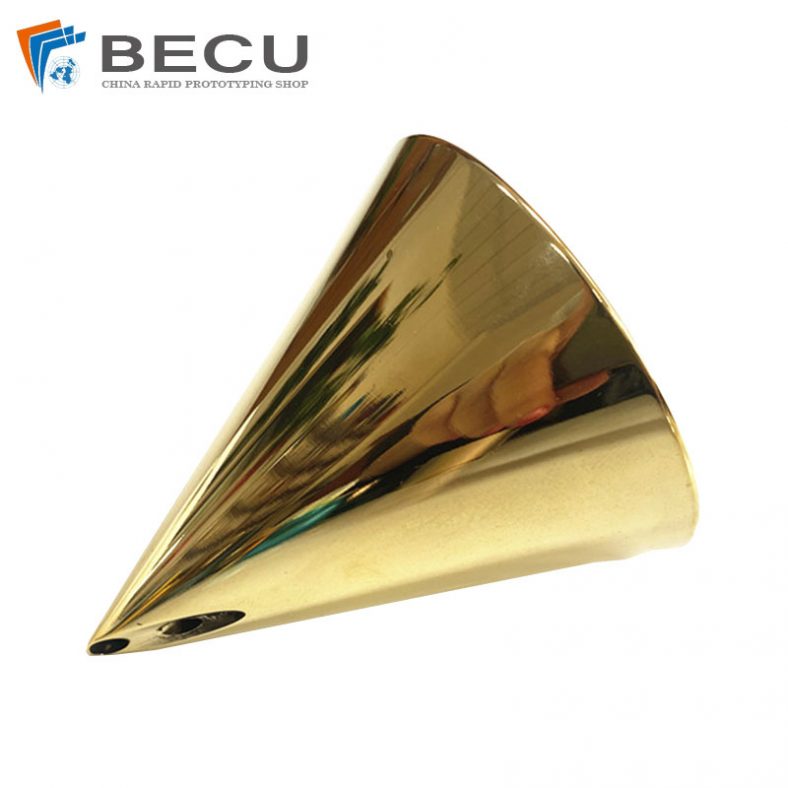

Precision Turning Brass 353 Cone Housing

-

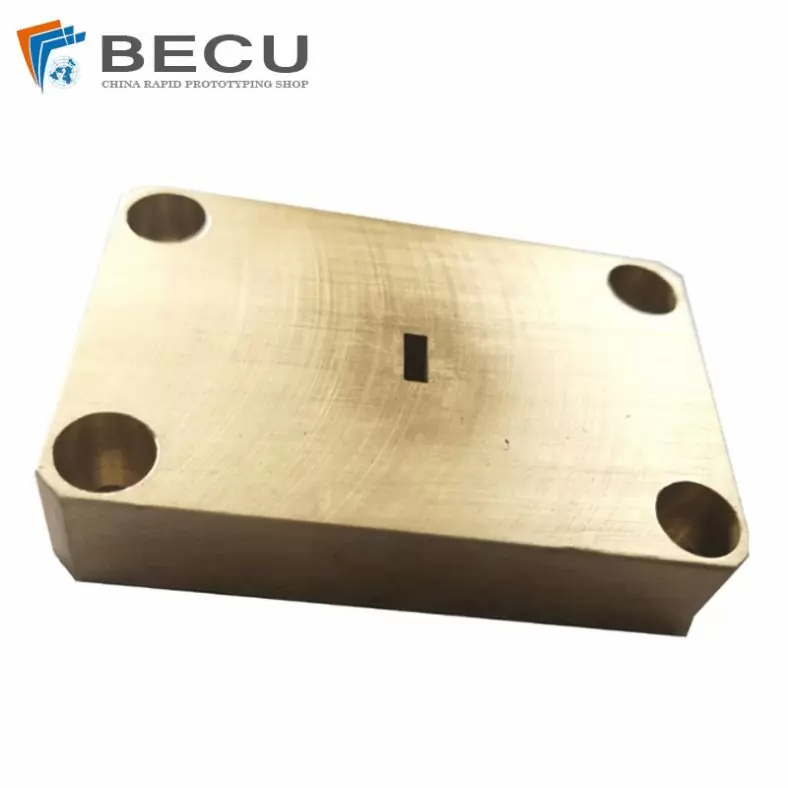

5 Axis Turn-Mill Machining Brass Parts

-

Swiss CNC Machining And Turning Brass 360 Shaft

-

Milling Machining Wear-Resistant Precision Brass Spare Parts

The Material Type Of CNC Machining Brass Alloy

The strength and corrosion resistance of special brass are better than ordinary brass, and the casting performance has also been improved to a certain extent. In production, special brass is often used to manufacture important marine parts such as propellers and compression nuts and other corrosion-resistant parts.

- Ordinary brass: radiators, condenser pipes, thermal bimetals, bimetallic plates, metal meshes for the paper industry, cartridge cases, springs, screws, washers;

- Tin brass: elastic casing for automobile tractors, pipes for marine vessels, condenser pipes, ship parts;

- Lead brass: parts of automobiles, tractors and clocks, parts made by hot stamping or cutting;

- Iron brass: suitable for parts that work under friction and seawater corrosion conditions;

- Manganese Brass: Manufacturing marine parts and telecommunications equipment, corrosion-resistant parts, propellers;

- Aluminum Brass: High-strength cnc machining parts in seawater work, ships and other corrosion-resistant parts, screws and compression nuts working under heavy load conditions.