Kitchen Appliance Valve Core

- No.: Brass

- Color: Custom

- Surface Treatment: Oxidation

- Product Material: Brass Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: CNC Machining Cookware

- Production Process: Brass CNC Milling

- Size: According To Customer’s Drawings

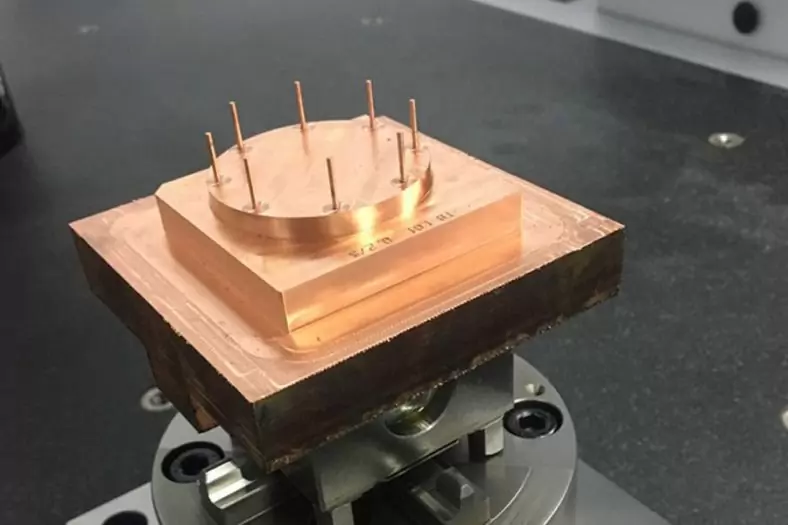

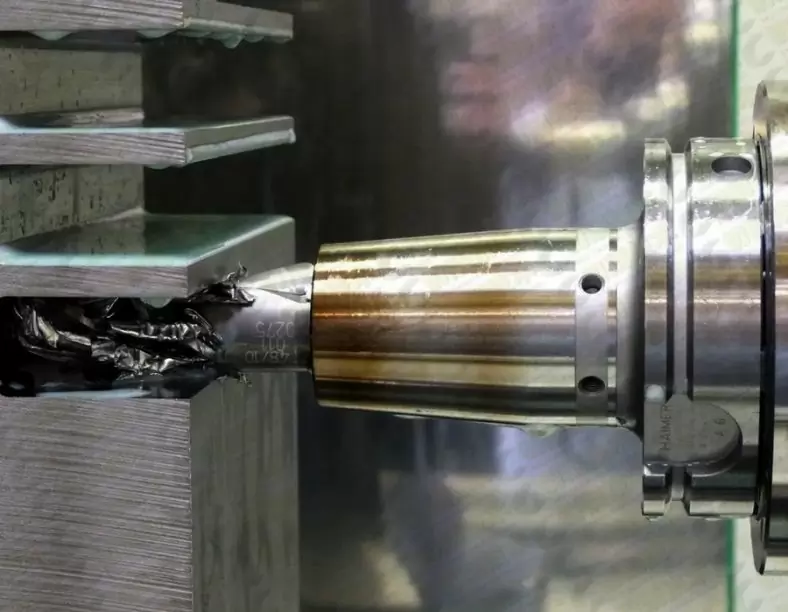

High-Quality CNC Machining Brass Natural Gas Kitchen Appliance Valve Core

In natural gas appliances, including those used in kitchens, brass valves are commonly used due to their durability and resistance to corrosion. Valves play a crucial role in controlling the flow of natural gas to appliances like stoves, ovens, and water heaters. The core of a valve, often referred to as the valve cartridge or valve stem, is the part that regulates the flow of gas.Brass is a common material for gas valves due to its resistance to corrosion and ability to withstand the high-pressure conditions typically found in gas lines.There are various types of gas valves, including manual shut-off valves, thermostatic control valves, and safety valves. The specific type of valve used depends on the appliance and its function.

The Advantages Of CNC Machining Brass Natural Gas Kitchen Appliance Valve Core

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of CNC Machining Brass Natural Gas Kitchen Appliance Valve Core

| Material | Brass |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

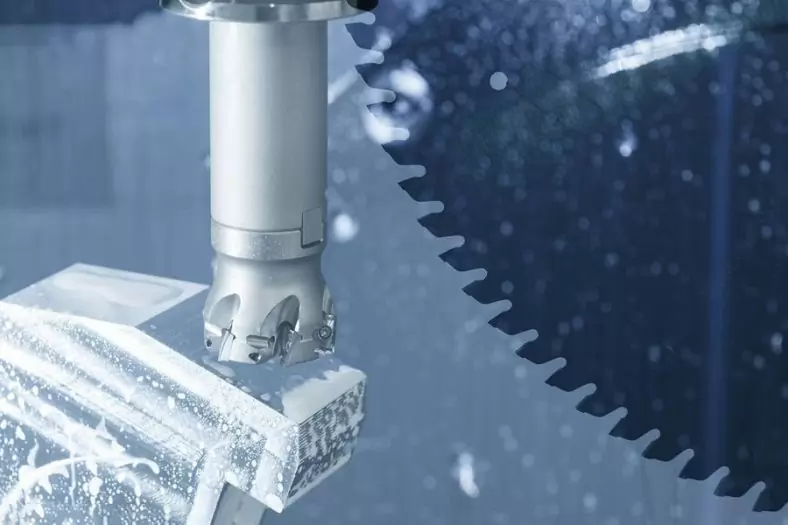

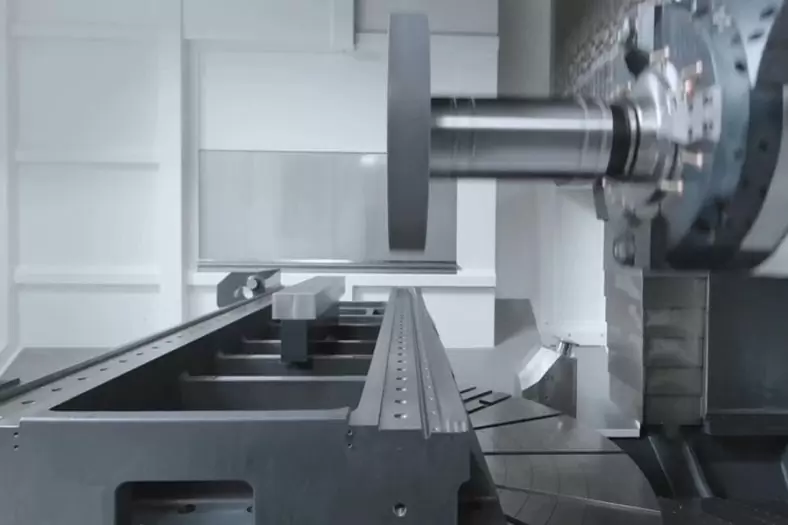

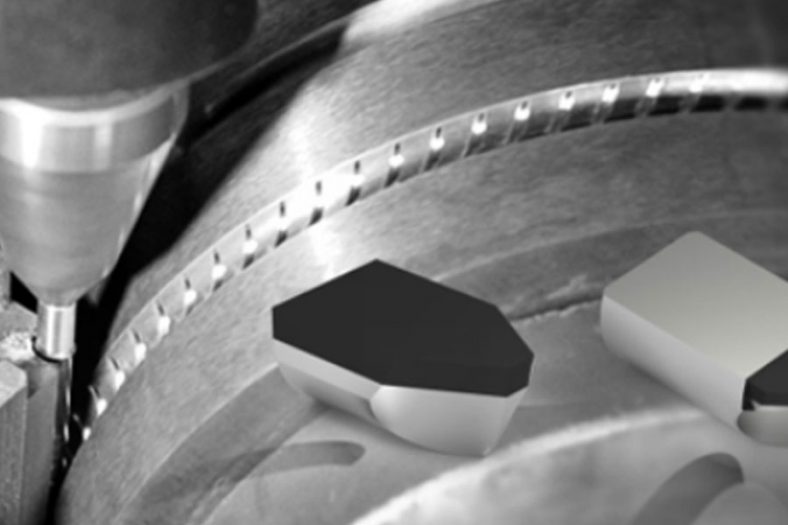

| Main Process | Milling, Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Cookware |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.