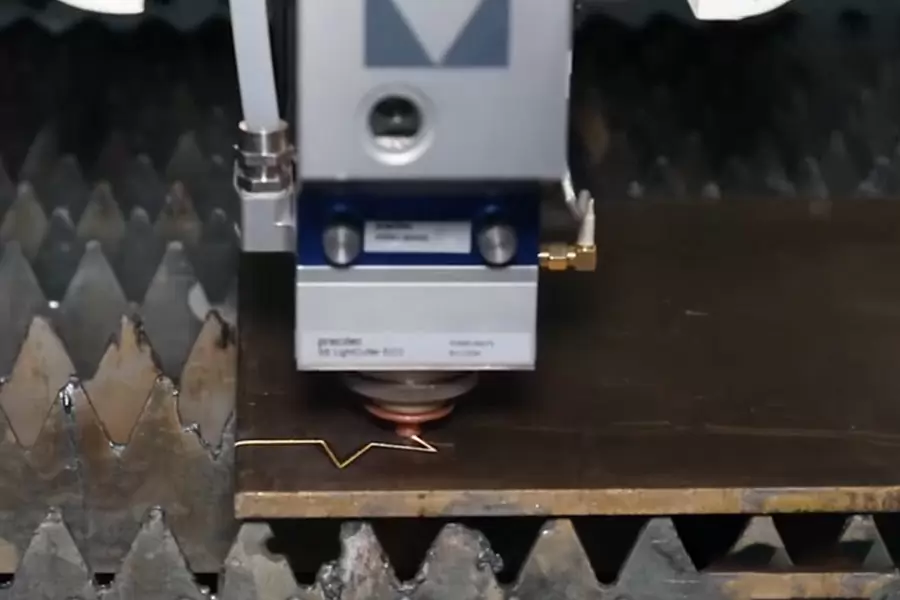

Brass Laser Cutting

Like aluminum, brass and copper have high reflectivity and very good thermal conductivity, so it is necessary to use laser cutting machine with “anti reflection device” for cutting.Laser cutting brass with thickness less than 1mm can be cut with nitrogen, and brass with thickness less than 2mm can be cut. High cutting efficiency. Due to the transmission characteristics of the laser, the laser cutting machine is generally equipped with multiple CNC workbenches, and the entire cutting process can be fully CNC controlled. During operation, it is only necessary to change the NC program to apply to the cutting of parts with different shapes, which can be used for both two-dimensional and three-dimensional cutting.

With the continuous development of the market, professional brass laser cutting processing is not only used in the fitness equipment industry, but also in other fields, such as medical equipment, automation enterprises, display equipment, automobile industry, metal furniture, solar energy manufacturing and other industries.

As one of the most popular cutting technologies, laser cutting has been widely used in art processing. Compared with the traditional cutting process, laser cutting can cut workpieces with better quality and reduce processing procedures. Moreover, with the increase of workpiece thickness, compared with the traditional sheet metal cutting, the process of cutting, blanking and bending requires a lot of molds and more cost investment. Laser cutting does not need to go through these processes, and the cutting effect is better in quality.

Compared with the traditional plate processing method, the optical fiber cutting machine has high cutting quality, high cutting speed and high flexibility. These are the advantages of laser cutting. This technology is very popular.

The Brass Alloy Grades Of Metal Laser Cutting

Brass (copper alloy) uses higher laser power and auxiliary gas is air or oxygen, which can cut thinner plates. The grades of brass alloys are as follows:

| GB | UNS | BS | DIN |

|---|---|---|---|

| H68 | C26200 | CuZn33 | |

| H65 | C26800 | CZ107 | CuZn36 |

| H63 | C26800 | CuZn37 | |

| H62 | C27400 | CZ108 | CuZn37 |

| HPb63-3 | C34500 | CZ119 | CuZn36Pb1.5 |

| HPb60-2 | C36000 | ||

| HPb59-3 | CZ120 | ||

| HPb59-2 | C35300 | CuZn39Pb2 | |

| HPb59-1 | C37800 | CZ122 | CuZn39Pb3 |

| HPb58-2.5 | C38000 | CZ121 | CuZn |

Brass Laser Cutting Services – CNC Laser Cut Brass Parts Suppliers & Manufacturer

Brass is an alloy made of copper and zinc.In Be-cu.com,Brass laser cutting is used in a wide range of applications and industries, including plumbing, oil and gas and the medical and dental industries. Brass alloy is one of the easiest materials to laser cut. The material properties are the go to for applications where components need to conduct electricity and/or be corrosion resistant.

Brass laser cutting is just simply cost efficient, and extremely durable. Laser cut brass fittings are often used in electronic hardware because of its low strength and weight properties. Over the years we have manufactured millions of laser cutting components for a number of industries made from brass. You can trust in us to have repeat success in any of your brass laser cutting needs.

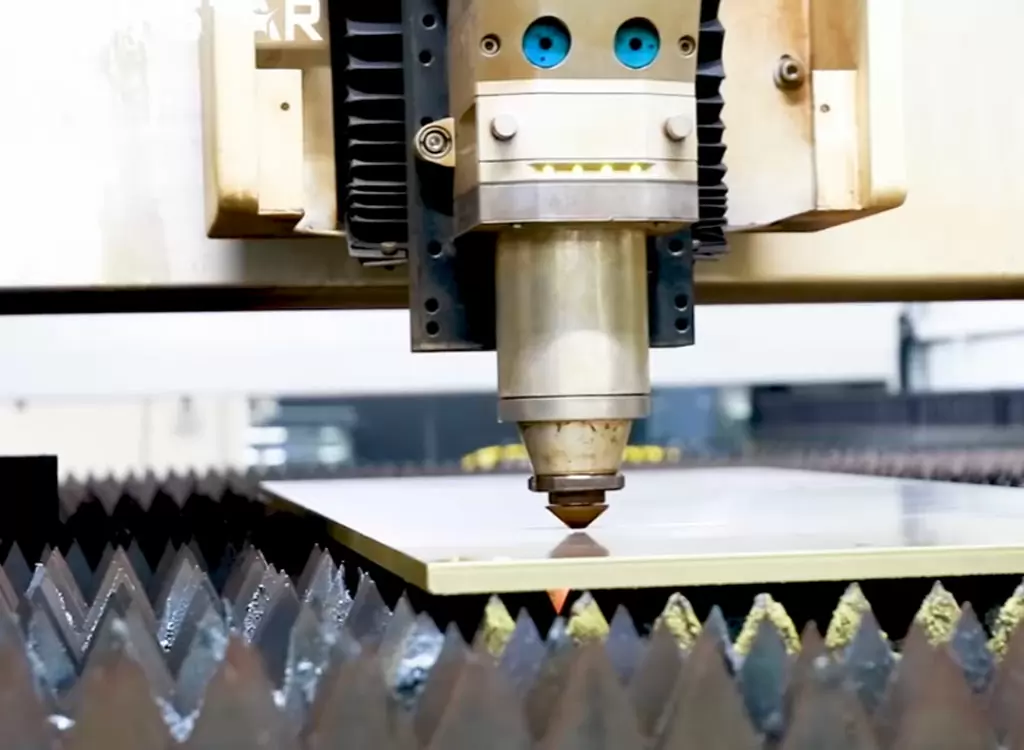

Our Brass Laser Cutting Capabilities

ISO 9001:2015 certified Brass plate laser cutting & Brass tube laser cutting services to eliminate burrs & secondary operations in fabricated tubing assemblies. Plate cutting to 1 in. thick, 60 in. x 120 in., tolerances to plus/minus .002 in., CAD/CAM nesting software increases sheet yield resulting in less material scrap, quantities from one piece to thousands.

Rapid laser inspection with 1st article inspection & reports, no tooling, reverse engineering capabilities. Secondary services include machining, aqueous cleaning, coping, beading, drilling, flattening, flaring, notching, piercing, slotting, swaging, threading, bar coding, brush & tumble deburring, chamfering, JIT-SPC, plating, powder coating, reverse engineering, packaging & assembly. ISO certified QC & inspections.

Why Use Our Brass Laser Cutting Services

The Top 6 Reasons:

- No MOQ:One-off Brass laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom brass sheet metal fabrication process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

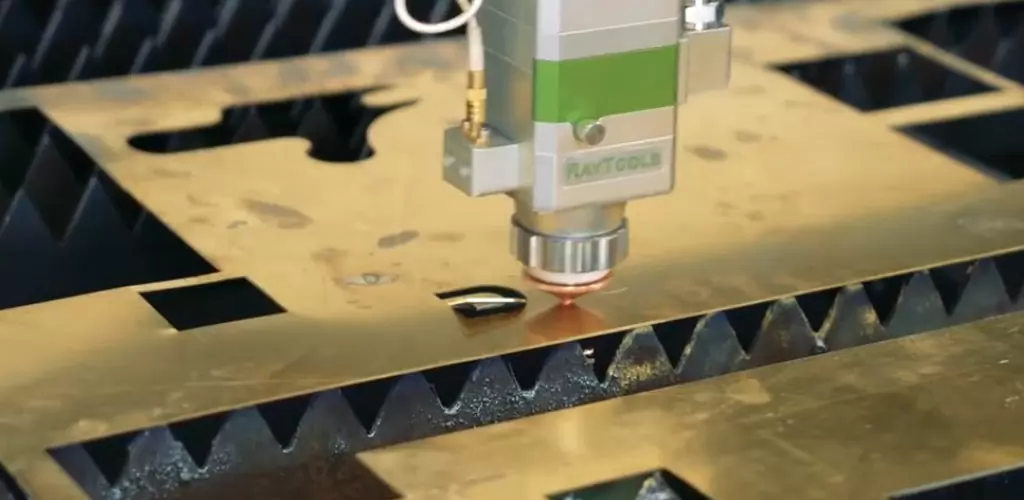

Combine With Other Brass Manufacturing Processes

Most laser shops will only give quotations for laser cutting as a standalone process. But when the quantity of new parts goes up to hundreds or more, you need a better solution for the best results. For some of these conplex parts, it is better not to cut them from a solid block at all, but to use tool-based fabrication or edm cutting assisted by milling.

When making Brass cutting parts, Be-cu.com offers several ways to combine precision laser cutting with other manufacturing processes in order to create more complex parts that can be made in large quantities. These process combinations can maximize the functionality of Brass while still enjoying the benefits of other production processes.

CNC Bending,Welding, Laser Engraving, Metal Etching,Precision machining, stamping, EDM, Wire Cutting and more can all be complemented with laser cutting to make better Brass components. No matter the test and no matter what properties are required.

Our Case Studies Gallery Of Brass Laser Cutting

Brass laser cutting produces durable, end-use Brass parts with a wide selection of Brass materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy, robotics and more.Compared with traditional laser cutting companies, we have a large amount of precision machines, so we can do precision post-machining in house.Send your CAD files or inquiry to us, a fast, free online laser cutting quote of required Brass components will be back. Get your Brass Laser Cut Parts into fabrication in the shortest time.

The Advantage Of Brass Laser Cutting

- Thin Cutting Seam: The cutting seam of laser cutting is generally 0.1mm-0.2mm

- The cutting surface is smooth: the cutting surface of laser cutting has no burrs and no slag.

- Small thermal deformation: The laser processing of laser processing has thin slits, high speed and concentrated energy, so the heat transmitted to the material to be cut is small, and the deformation of the material is also very small.

- It is suitable for the processing of large-size products: the mold manufacturing cost of large-size products is very high, and laser processing does not require any mold manufacturing. For this, we recommend changing the needle to one size larger, and try to adjust the feeding time of the feeding dog. Slow down, and you can fix this problem. Moreover, laser processing completely avoids the slump formed when the material is punched and sheared, which can greatly reduce the production cost of the enterprise and improve the grade of the product.

- It is very suitable for the development of new products and shortens the research and development cycle: once the product drawings are formed, laser processing can be carried out immediately, and you can get the physical objects of the new products in the shortest time.

- Material saving: laser processing adopts computer programming, laser equipment can cut different shapes of products, and different combinations of upper and lower thread thicknesses of the interlock sewing machine will definitely produce different sewing effects. Under normal circumstances, the upper and lower lines should be the same thickness.