Brass 360 Shaft

- No.: Brass

- Color: Custom

- Surface Treatment: Oxidation

- Product Material: Brass Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Precision Cnc Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Shaft

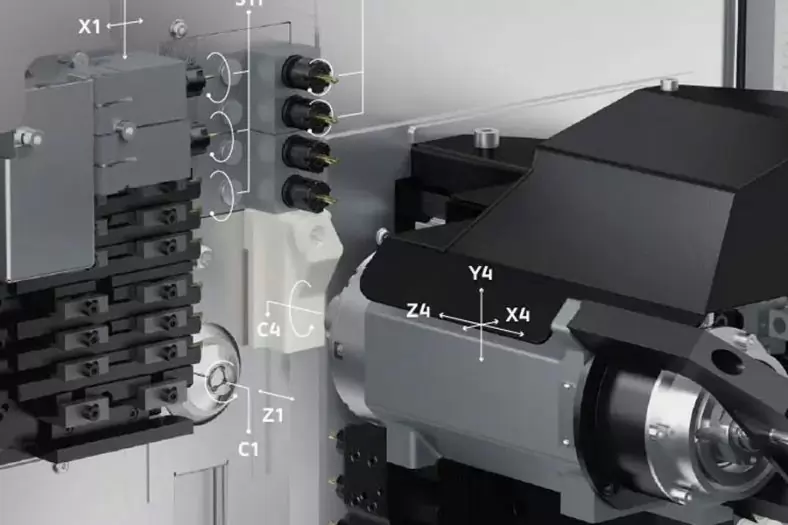

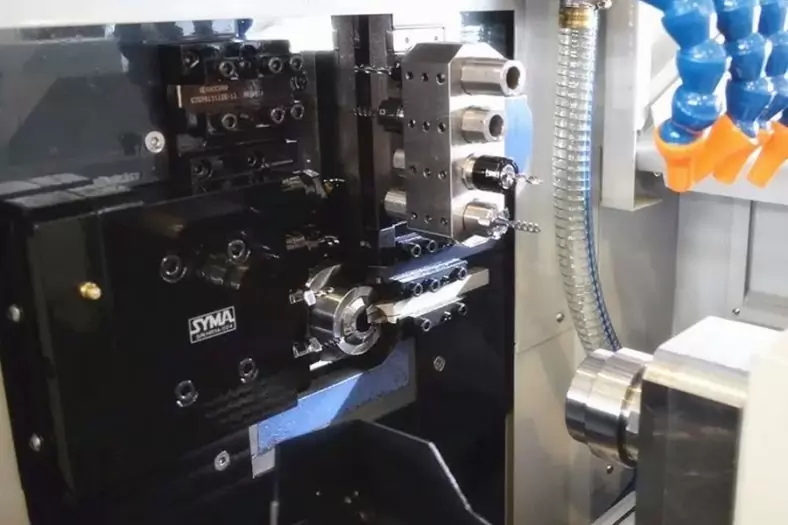

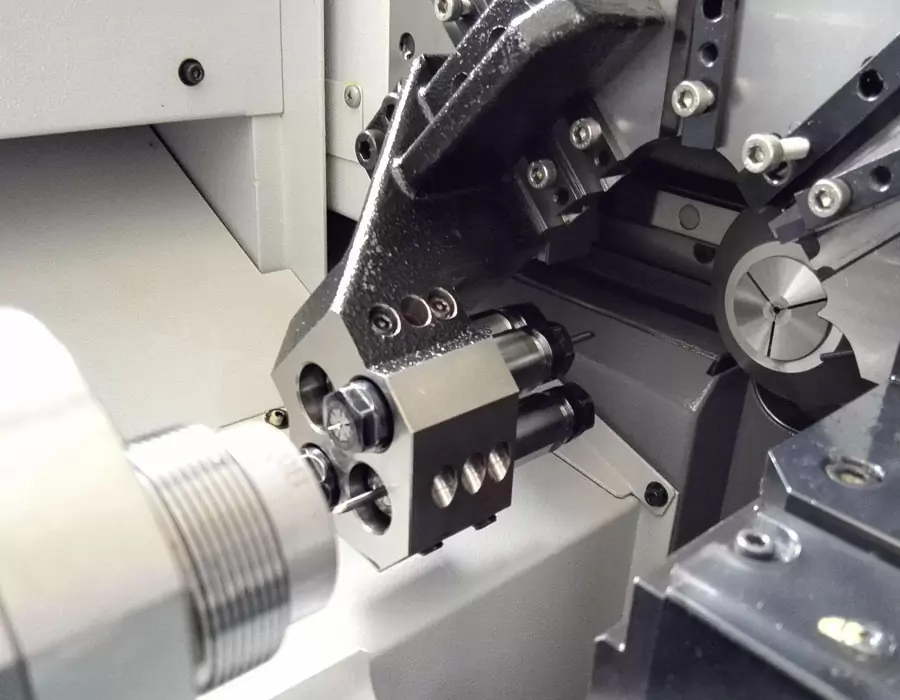

- Production Process: Brass Swiss Machining

- Size: According To Customer’s Drawings

High-Quality Swiss CNC Machining And Turning Brass 360 Shaft

At Be-cu.com, we pride ourselves on the ability to adapt to our customers needs. With this mindset, we’ve achieved long term success in manufacturing intricate components for the world’s leading Swiss CNC Machining And Turning Brass 360 Shaft’s in a range of markets. In order for this success to be made possible, we’ve tailored our systems and processes to maximize productivity, efficiency and quality by utilizing Lean Manufacturing initiatives from inception to completion of each manufactured component.

The Advantages Of Swiss CNC Machining And Turning Brass 360 Shaft

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Swiss CNC Machining And Turning Brass 360 Shaft

| Material | Brass |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Shaft |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Prototype Company

If you need intricate components fabricated by a reliable precision CNC parts manufacturer, you can trust with CNC Swiss machining services offered at be-cu prototype, which is a China top cnc machining company that is specialized in CNC services and precision hardware production for decades of years, and have the capability to provide Swiss CNC machining services with the latest Swiss turning and machining technology for the manufacturing needs of various industries all over the world. With advanced Swiss lathe and Swiss machines, as well as other manufacturing facilities, our seasoned experts and technicians can give you the most cost-effective solutions and produce the highest quality Swiss machined parts based on the industry standards and customer requirements. From 5 axis milling service to CNC Swiss machining services, from Swiss CNC turning to wire EDM, no matter what type of CNC components you call for, our team will help you to approach the standard. Welcome to contact us to get a free quote fast.

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Swiss Turning Stainless Steel 17-4 PH Positioning Bushing

-

Precision Swiss Turning Titanium Alloy Medical Shaft

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Swiss CNC Machining And Turning Brass 360 Shaft