The Characteristics Of Swiss Machining Stainless Steel

The machinability of stainless steel is much worse than that of medium carbon steel. Taking the machinability of ordinary No. 45 steel as 100%, the relative machinability of austenitic stainless steel 1Cr18Ni9Ti is 40%; ferritic stainless steel 1Cr28 is 48%; martensitic stainless steel 2Cr13 is 55%. Among them, the machinability of austenitic and austenitic ferritic stainless steels is the worst. Stainless steel has the following characteristics in the cnc machining process:

- Serious Work Hardening: Among stainless steels, the work hardening phenomenon of austenitic and austenitic ferritic stainless steels is the most prominent. For example, the strength s of austenitic stainless steel after hardening reaches b1470 ~ 1960MPa, and with the increase of s, the yield limit s increases; the s of austenitic stainless steel in the annealed state bs does not exceed σb30% ~ 45%, and after work hardening s85% to 95%. The depth of the work hardened layer can reach 1/3 of the machining depth or more; the hardness of the hardened layer is 1.4 to 2.2 times higher than the original. Because the plasticity of stainless steel is large, the character is distorted during plastic deformation, and the strengthening coefficient is large; and the austenite is not stable enough, under the action of cutting stress, part of the austenite is transformed into martensite; in addition, compound impurities are in the cutting process. Under the action of heat, it is easy to decompose and disperse, so that a hardened layer is produced during cutting. The work hardening phenomenon produced by the previous feed or the previous process seriously affects the smooth progress of the subsequent process.

- Large Machining Force: stainless steel has large plastic deformation during the cutting process, especially austenitic stainless steel (its elongation is more than 1.5 times that of No. 45 steel), which increases the machining force. At the same time, the work hardening of stainless steel is serious and the thermal strength is high, which further increases the cutting resistance, and the curling and breaking of the chips is also difficult. Therefore, the cutting force of machining stainless steel is large. For example, the unit cutting force of turning 1Cr18Ni9Ti is 2450MPa, which is 25% higher than that of No. 45 steel.

- High Cutting Temperature: The plastic deformation and the friction with the tool are very large during cutting, which generates a lot of machining heat; plus the thermal conductivity of stainless steel is about ½ to ¼ of that of No. 45 steel, a large amount of machining heat is concentrated in the cutting area and the cutting tool. – On the interface where the chips contact, the heat dissipation conditions are poor. Under the same conditions, the cutting temperature of 1Cr18Ni9Ti is about 200°C higher than that of No. 45 steel.

- Chips Are Not Easy To Break And Stick Easily: the plasticity and toughness of stainless steel are very large, and the chips are continuous during turning, which not only affects the smooth operation of the operation, but also crushes the processed surface. Under high temperature and high pressure, stainless steel has a strong affinity with other metals, which is easy to produce adhesion and form built-up edge, which not only aggravates tool wear, but also causes tearing and deteriorates the machined surface. This feature is more pronounced for martensitic stainless steels with lower carbon content.

- The Tool Is Easy To Wear: the affinity effect in the process of machining stainless steel makes the tool-chip bond and diffuse, so that the tool produces bond wear and diffusion wear, resulting in crescent craters on the rake face of the tool, and the machining edge will also form tiny In addition, the hardness of carbide (such as TiC) particles in stainless steel is very high, and direct contact with the tool during cutting, friction, scratching of the tool, and work hardening will aggravate tool wear.

- Large Linear Expansion Coefficient: The linear expansion coefficient of stainless steel is about 1.5 times that of carbon steel. Under the action of machining temperature, the workpiece is prone to thermal deformation, and the dimensional accuracy is difficult to control.

Swiss Machining Stainless Steel Services – Custom Stainless Steel Swiss CNC Machining Parts

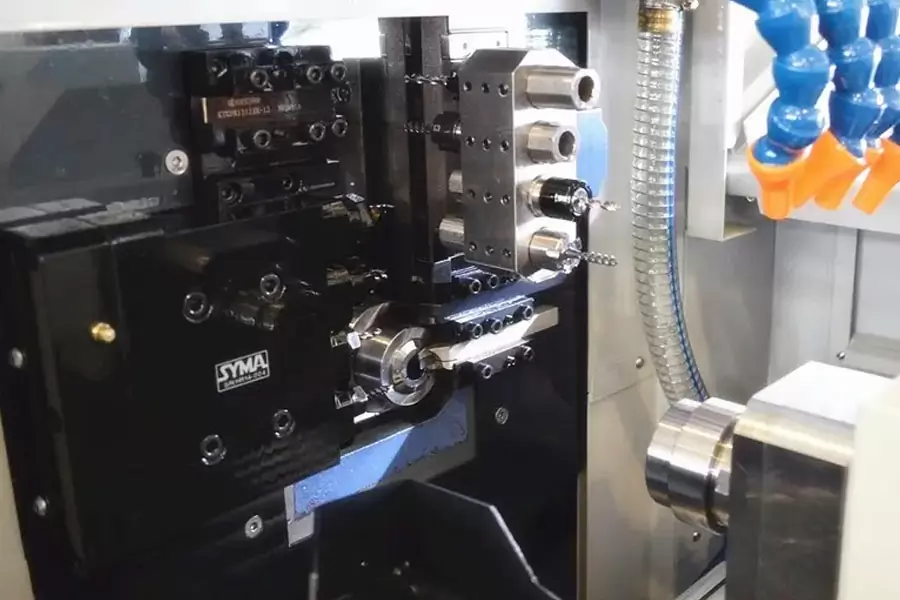

Looking for reliable, quick-turn swiss machining stainless steel services suppliers and swiss machining product manufacturers?High quality, carefully maintained tooling is a key to successful stainless steel swiss cnc machined parts. This is why Be-cu.com maintains a complete in-house tooling capability. Additional benefits come from the extensive selection of automated machining equipment at Be-cu (including CNC Swiss, multi-spindle and CNC milling equipment under Esprit CAD/CAM control.)

All these advantages, combined with 30+ years of expertise cnc swiss cnc machining stainless steel, make Be-cu swiss machining company you can be confident in to come through on the delivery day. Experience the Be-cu stainless steel advantage for yourself by contacting us on your next component project.

Why Choose Our Stainless Steel Swiss Machining Service?

- Save time and money for your stainless steel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of stainless steel grades and alloy materials can be machined

- Custom complex stainless steel machined parts and components at specific tolerances

- High speed swiss machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Stainless Steel Swiss Machining Case Studies

Swiss Machining processes such as precision swiss machining and cnc turning are today considered the most economic way to make stainless steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making stainless steel concept models and precise functional components. Understanding the properties of different stainless steel alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on stainless steel alloy. Be-cu prototyping company provides a range of solutions for the swiss machining of stainless steel parts.

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

Swiss Turning Stainless Steel 17-4 PH Positioning Bushing

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

Swiss Machining Stainless Steel Pin Cylindrical Discharge Needle

-

Precision Swiss Machining Tooth Drive Screw Rod

-

Cnc Swiss Machining Stainless Steel 304 Taper Needle

-

Automatic Swiss Cnc Machining Stainless Steel 316 Special Long Screw