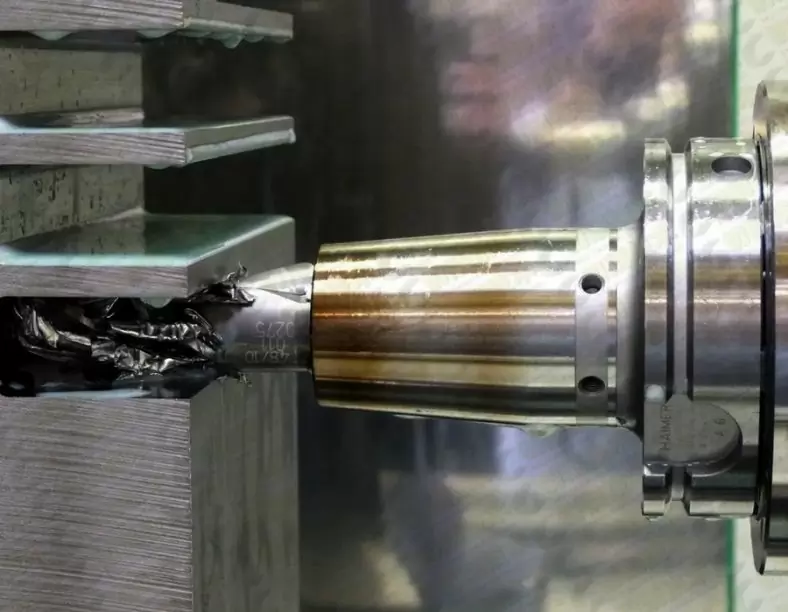

Beauty Instrument Cavity

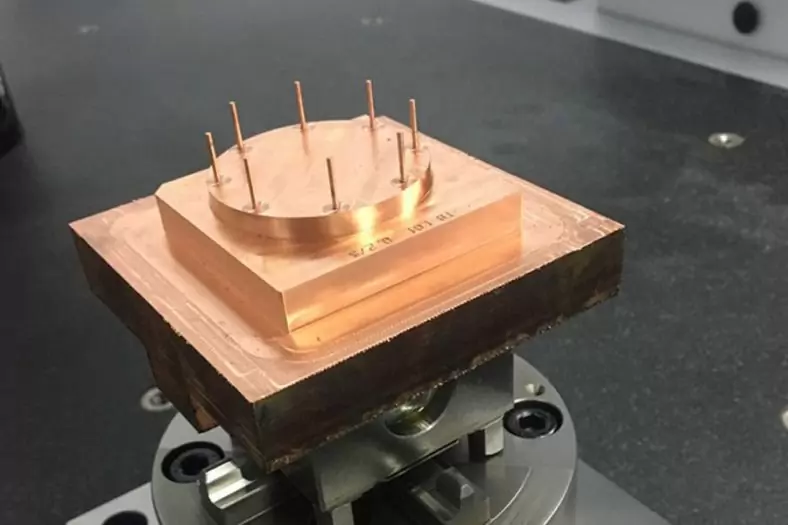

- Product Name: Beauty Instrument Cavity

- No+Color:Custom

- Surface Treatment: Polishing

- Product Material: Copper Alloy

- Proofing Cycle:7 days(100000 pcs/M)

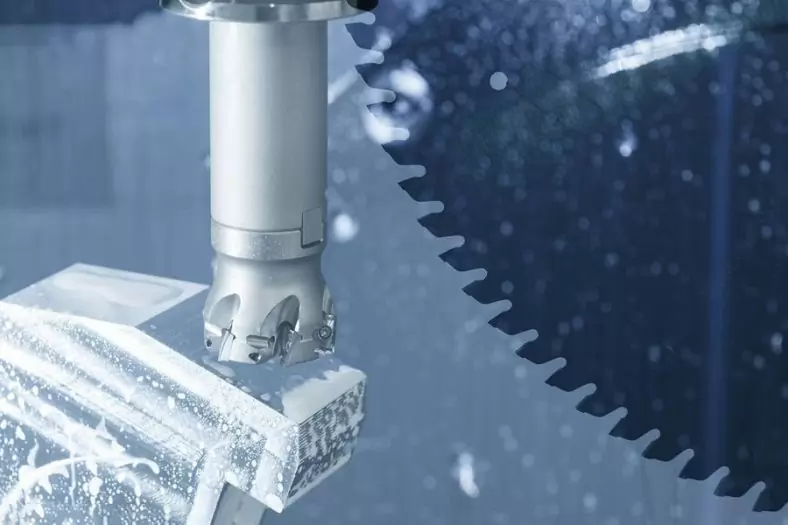

- Application: Turn-Mill Machining Or Swiss Machining Copper

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Machinery Parts

- Production Process: Electronic Cnc Machining

- Size: According To Customer’s Drawings

High-Quality CNC Turning-Milling Machining Copper Facial Massage Roller

A facial massage roller is a beauty tool designed to help improve the health and appearance of your skin through facial massage. It typically consists of a handle and one or two rolling heads made of materials like jade, rose quartz, or metal. Facial massage rollers are often used to relax facial muscles and reduce stress. The rolling motion can have a calming effect, making it a popular choice for self-care routines.

Massaging your face with a roller can stimulate blood circulation, which may help improve the delivery of oxygen and nutrients to your skin cells. This can result in a brighter and more radiant complexion.Many people use facial rollers to promote lymphatic drainage. Gently rolling the tool in specific directions on your face can encourage the lymphatic system to eliminate toxins and reduce puffiness.Facial rollers can also be used in conjunction with skincare products. After applying serums or moisturizers, you can use the roller to help the product penetrate your skin more effectively.

A CNC (Computer Numerical Control) machining facial massage roller refers to a facial massage roller that has been manufactured or crafted using CNC machining techniques. CNC machining is a precise and automated manufacturing process commonly used to create intricate and detailed parts and products, including various tools and equipment.When it comes to a facial massage roller, CNC machining may be used to create the roller’s rolling head or any other component with precision. A facial massage roller created using CNC machining techniques is likely to be of high quality and precision due to the automated and controlled nature of the manufacturing process. This can result in a smoother and more effective massage experience for users. However, the choice of material and design also plays a significant role in the overall quality and performance of the facial massage roller.

The Advantages Of CNC Turning-Milling Machining Copper Facial Massage Roller

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of CNC Turning-Milling Machining Copper Facial Massage Roller

| Material | Copper |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

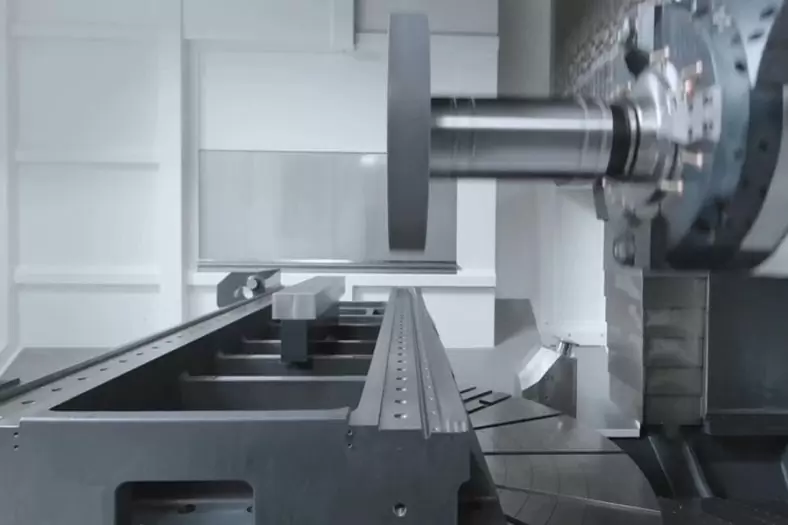

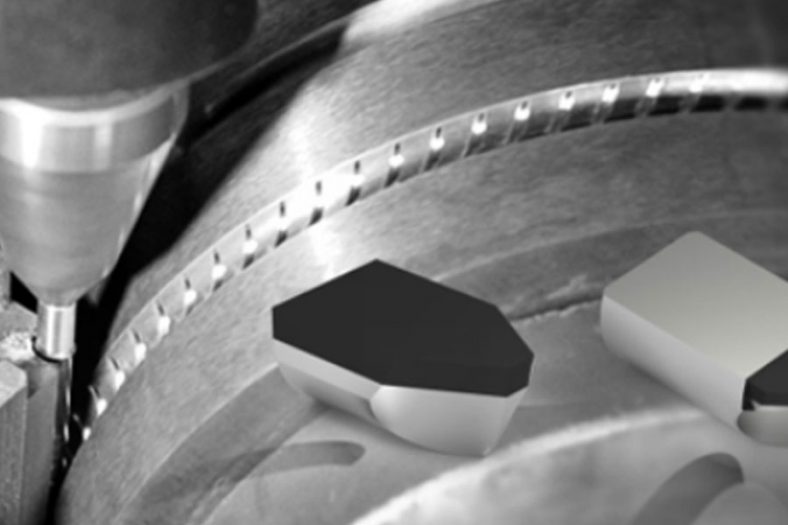

| Main Process | CNC Turning ,Cnc Milling,Cnc Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Electronic,Beauty Device |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.