What Is Titanium Swiss Machining

Titanium alloys are obtained by using two different microstructures formed by titanium at different temperatures, adding different types of elements to gradually change the phase transition temperature and phase content. Titanium alloys are used in aviation due to their superior performance. , aerospace, petroleum, chemical, automobile and other industrial production fields have been widely used, but in the process of Swiss CNC Machining titanium alloy, there are processing problems such as low cutting efficiency, poor tool wear resistance, and difficult chip removal. The characteristics of titanium alloys are as follows:

- High strength: Titanium alloy has low density and high strength, and its strength is greater than that of ultra-high strength steel.

- Poor thermal conductivity: The thermal conductivity and thermal conductivity of titanium alloy are small, only 1/15 of that of aluminum alloy and 1/5 of that of 45 steel. The cutting heat should not be dissipated, which will inevitably cause a large temperature difference and thermal stress during the cutting process. , resulting in faster tool wear.

- Small cutting force: Although the cutting force of titanium alloy is only 1/2~1/3 of that of 45 steel, the contact area between the cutting and the rake face is small, so the pressure on the cutting edge is much greater than that of cutting 45 steel. .

- Active chemical properties: At high temperature, titanium alloy reacts chemically with N element in the air to form a TiN work hardening layer.

- The friction coefficient of titanium alloy is large: the coefficient of deformation of titanium alloy is small, the coefficient of friction between the tool and the workpiece is large, and the springback deformation is large, and the workpiece is easily deformed by force, which seriously affects the machining accuracy of the workpiece.

Swiss Machining Titanium Services – Custom Titanium Swiss CNC Machining Parts

Looking for reliable, quick-turn swiss machining titanium services suppliers and swiss machining product manufacturers?

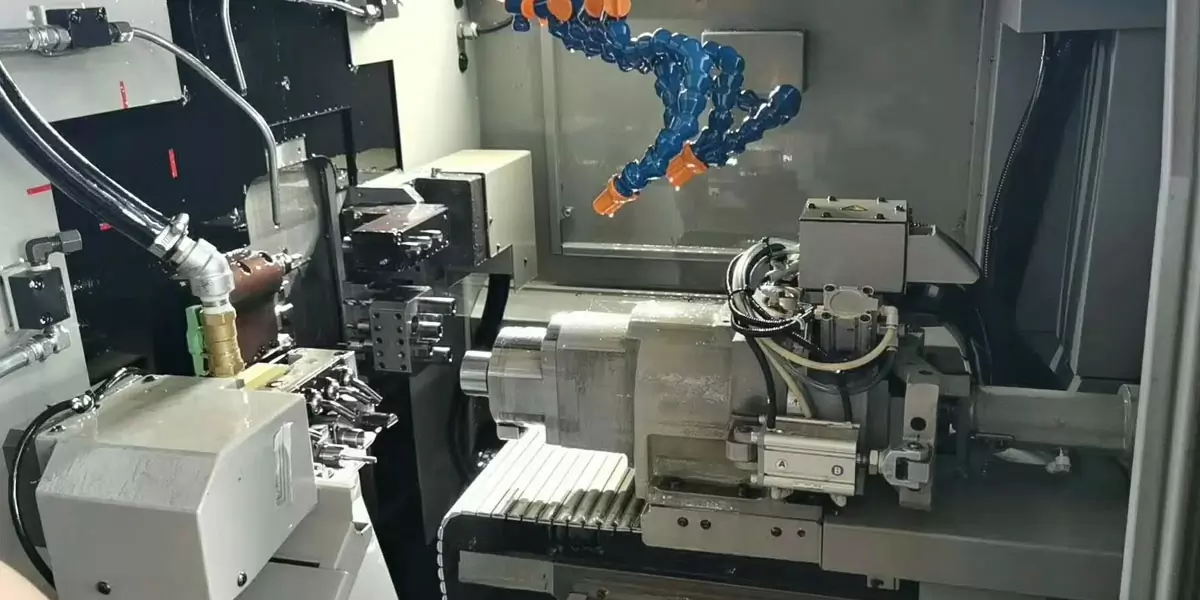

Delivering a titanium project on spec, on time and on budget is one of the toughest challenges in the swiss machining industry. The experts at Be-cu.com have learned, through decades of experience, the productivity secrets needed to inspire complete confidence in the users of top quality titanium swiss machining. Be-cu can customize and manufacture any titanium precision swiss screw machine parts to fit your needs.

Because the quality and accuracy of tooling is crucial for titanium work,Be-cu maintains its own in-house tool facility. EDM technology is used to create quality tools that can cut titanium without degradation to the work piece or cutting tool.

The ultimate success secret to our titanium swiss machined parts is the keen eye and experienced hand of the Be-cu craftsmen who oversee the titanium machining process. They put decades of experience into making sure cutting speeds, feed rates, cutting fluids and tool conditions are perfectly maintained for precise titanium swiss CNC machining.

Swiss machining titanium has several advantages over other materials. Titanium swiss machined parts are known for their high strength and weight; it is also ductile, corrosion resistant against salt and water, and has a high melting point, making it the perfect option for many industries and applications.

Why Choose Our Titanium Swiss Machining Service?

- Save time and money for your titanium project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of titanium grades and alloy materials can be machined

- Custom complex titanium machined parts and components at specific tolerances

- High speed swiss machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Titanium Swiss Machining Case Studies

Swiss Machining processes such as precision swiss machining and cnc turning are today considered the most economic way to make titanium prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making titanium concept models and precise functional components. Understanding the properties of different titanium alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on titanium alloy. Be-cu prototyping company provides a range of solutions for the swiss machining of titanium parts.