What Is Aluminum Swiss Machining

Aluminum Swiss Machine is a slitting lathe, which is a lathe whose main shaft can move longitudinally. It originated in Switzerland and is also called a Swiss lathe. Mainly used for machining aluminum bars with a diameter of 1 ~ ~ 32mm (there are also larger, but not the mainstream). Widely used in instruments, meters, watches, cameras, home appliances, medical equipment, hardware, communication electronics, automobiles, military industry, aerospace and other fields.

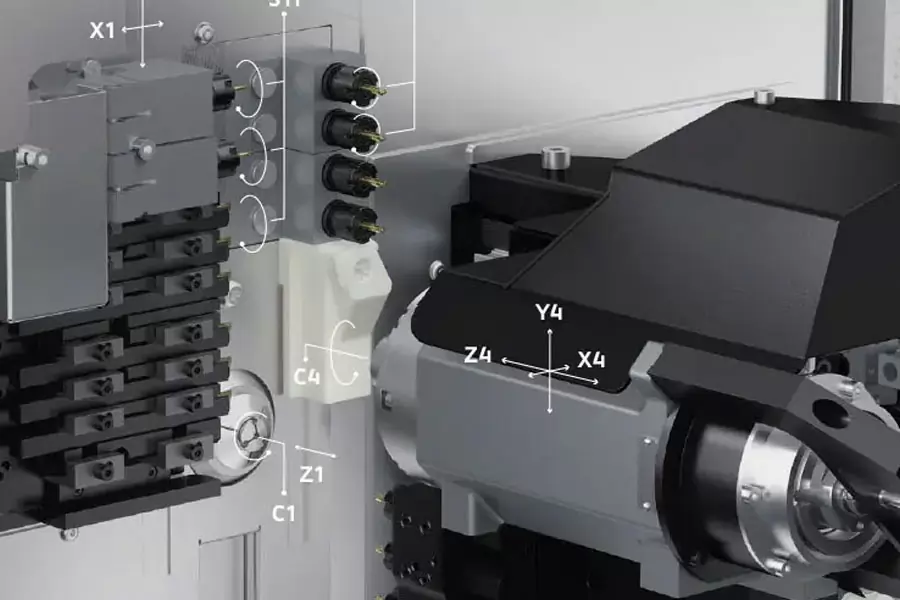

The spring chuck in the through hole of the main shaft holds the bar and rotates synchronously with the main shaft. There is a guide sleeve walking machine at the front end of the bar with a support guide sleeve to support the bar, and the headstock moves longitudinally (that is, the axis of the bar The direction of the Z axis of the machine tool is the direction of the machine tool), and the longitudinal cutting is completed; the radially distributed tools move radially (in the direction of the X and Y axes of the machine tool) to complete the radial cutting.

Swiss Machining Aluminum Services – Custom Aluminum Swiss CNC Machining Parts

Looking for reliable, quick-turn swiss machining aluminum services suppliers and swiss machining product manufacturers?

ISO 9001:2015 certified. 3, 4, 5 and 6-axis precision aluminum CNC Swiss machining services.CNC Swiss turning, milling, boring, deburring, drilling, knurling, reaming, broaching, thread cutting, roll threading and tapping services are offered. Capable of machining parts from 0.01 to 1 5/8 in. dia. with +/- 0.0003 in. tolerance.

Prototype and low to high run production volume are available. Suitable for toys, industrial brakes, controls, connectors, fasteners, fittings, shafts, valves, pins, spindles, bushings, spacers, standoffs, sensors, machinery, engine, turbine, hydraulic, turbomachinery components and construction equipment applications. Blanket orders are accepted. Serves the aerospace, automotive, electronics, fluid power, HVAC, marine, medical, mining, pulp and paper industries. JIT delivery.

Why Choose Our Aluminum Swiss Machining Service?

- Save time and money for your aluminum project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be machined

- Custom complex aluminum machined parts and components at specific tolerances

- High speed swiss machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Aluminum Swiss Machining Case Studies

Swiss Machining processes such as precision swiss machining and cnc turning are today considered the most economic way to make aluminum prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making aluminum concept models and precise functional components. Understanding the properties of different aluminum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on aluminum alloy. Be-cu prototyping company provides a range of solutions for the swiss machining of aluminum parts.