Laser Cutting For Acrylic

Laser cutting acrylic is a precise and efficient process that uses a high-powered laser beam to cut through acrylic sheets or other acrylic materials with precision. Acrylic, often referred to by brand names like Plexiglas or Perspex, is a transparent thermoplastic material that is commonly used in various applications, including signage, displays, architectural models, jewelry, and more.

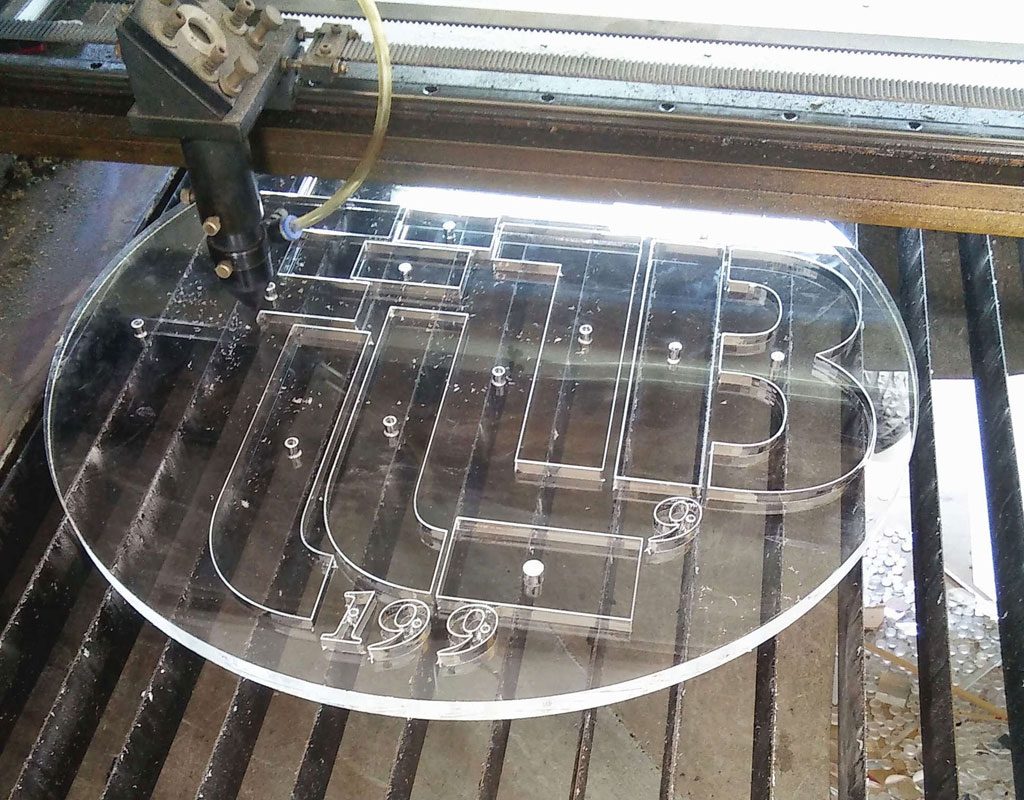

Laser cutting is a popular method for shaping and engraving acrylic due to its ability,Acrylic sheets are prepared for laser cutting by securely fixing them to the laser bed or platform. It’s important to ensure that the material is flat and well-supported to prevent warping or distortion during the cutting process. A high-powered laser beam is generated within the laser cutting machine.

The beam is focused through a series of lenses to a very fine point, creating an intense and concentrated energy source,to produce clean and precise cuts, intricate designs, and smooth edges.Be-Cu’s Acrylic laser cut services offer you high precision parts and prototypes at low costs and high quality.

Acrylic (PMMA) Material Properties

Cutting acrylic, or PMMA, parts exhibit good optical properties, UV stability, high gloss, and scratch resistance. It’s an economical alternative to polycarbonate when impact strength and overall toughness is not needed,It is also often used as a substitute for glass in applications where the combination of transparency and impact resistance is required.Here’s a chart summarizing some of the key material properties of Acrylic (Polymethyl Methacrylate or PMMA):

| Property | Value/Description |

|---|---|

| Chemical Formula | (C5O2H8)n (Polymer of Methyl Methacrylate) |

| Common Trade Names | Plexiglas, Lucite, Perspex, Acrylite, etc. |

| Transparency | Transparent to translucent |

| Density | 1.18 to 1.20 g/cm³ (varies with grade) |

| Refractive Index | 1.49 to 1.50 (similar to glass) |

| Melting Point | 160-220°C (320-428°F) |

| Glass Transition Temperature (Tg) | ~105°C (221°F) |

| Thermal Conductivity | 0.15-0.20 W/(m·K) (Low thermal conductivity) |

| Specific Heat Capacity | 1.35-1.60 J/(g·K) |

| Coefficient of Thermal Expansion (CTE) | 70-80 x 10^-6/°C (similar to glass) |

| Tensile Strength | 72-90 MPa (10,000-13,000 psi) |

| Flexural Strength | 90-120 MPa (13,000-17,000 psi) |

| Young’s Modulus | 2.1-3.0 GPa (300,000-435,000 psi) |

| Hardness (Rockwell Scale) | M75-95 (varies with grade) |

| Electrical Insulation | Excellent electrical insulator |

| UV Resistance | Good UV resistance, but can yellow over time |

| Chemical Resistance | Resistant to many chemicals |

| Water Absorption | Low water absorption |

| Flammability | Flammable (burns), but self-extinguishing |

Keep in mind that the specific properties of acrylic can vary depending on the grade and manufacturing process used. Acrylic is known for its optical clarity, lightweight nature, and ease of fabrication, making it a popular choice for various applications, including clear plastic sheets, signage, optical lenses, and more.

Acrylic Laser Cut Manufacturer – PMMA/Plexiglass Laser Cutting Service

Be-Cu Prototype is now offering complete Laser Acrylic Cutting And PMMA Precision Cut Service.

Be-Cu.com

Choosing Be-cu for fabricating your PMMA components will be the right decision with firm assurance of high quality but low cost. We can flexibly handle different orders whose quantities range from 10,000 pieces of PMMA Cut products to one piece of prototype in a fast production cycle. Capable of cutting parts ranges from 60 x 100 in. bed sizes to cut acrylic range from very thin to thick material, polishing thickness up to 1 in. and 0.010 in. accuracy.

While laser cutting Acrylic parts are relatively durable and versatile, this plastic is easy to fail and crack when suffering high compressive and tensile forces.Be-Cu has the capability to process fragile plastics carefully to avoid failure in the process of precision cutting, significantly decreasing the materials waste, saving costs, and then improving efficiency. What’s more, the accuracy of PMMA cut parts can be ensured at high speed in Acrylic fabrication with our advanced fiber laser cut technologies. Acrylic sheets are available in various colors and finishes, including transparent, translucent, and opaque options. The choice of color can significantly impact the aesthetics of the final product.Our work is completely based on your digital file to eliminate cutting errors. You can upload your CAD file to get a fast and free online quote, we’ll keep track of all the details and get your design to processing in a short time.

Acrylic Sheets For Laser Cutting

Acrylic sheets are a popular choice for laser cutting due to their transparency, ease of cutting, and the ability to produce precise and clean edges.Acrylic Type:

- Cast Acrylic: Cast acrylic sheets are often preferred for laser cutting. They have excellent optical clarity and are known for producing smooth, polished edges when laser cut. Cast acrylic is available in various colors and thicknesses.

- Extruded Acrylic: Extruded acrylic is a more cost-effective alternative but may not provide the same level of edge clarity as cast acrylic. It is suitable for applications where absolute optical perfection is not essential.

Consider the size of the acrylic sheets needed for your project. Acrylic sheets are available in standard sizes, and custom sizes can often be ordered to match your project’s requirements.

The Application Of Acrylic Laser Cut

Acrylic laser cutting is widely used in a variety of applications due to its precision, versatility, and ability to create intricate and custom designs. Some common applications of acrylic laser cutting include:

Signage and Displays

Architectural Models

Art and Decor

Aerospace and Engineering

Jewelry and Accessories

Awards and Trophies

Jewelry and Accessories

Awards and Trophies

Educational Materials

Custom Enclosures and Cases

Point-of-Purchase (POP) Displays

Cosplay and Costume Accessories

Electronic Front Panels

Acrylic Prototypes

Promotional Products

Medical and Laboratory Equipment

These are just some of the many applications of acrylic laser cutting. Its versatility and ability to produce high-quality, intricate designs make it a valuable tool in industries ranging from art and design to manufacturing and engineering.

Benefits Of Laser Cutting Acrylic

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient Laser Cut factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Custom Laser Cutting Acrylic Projects & Parts Case Studies

Using our top of the Acrylic laser cut service allows us to create unique design and features.We provide custom precision cutting services for a wide range of Acrylic. Using our high speed Acrylic laser cutter allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.Check out our extensive gallery that shows precision Acrylic laser cutting prototypes and parts from our valued customers.