Cnc Machining For Acrylic – What Is Acrylic Cnc Machining

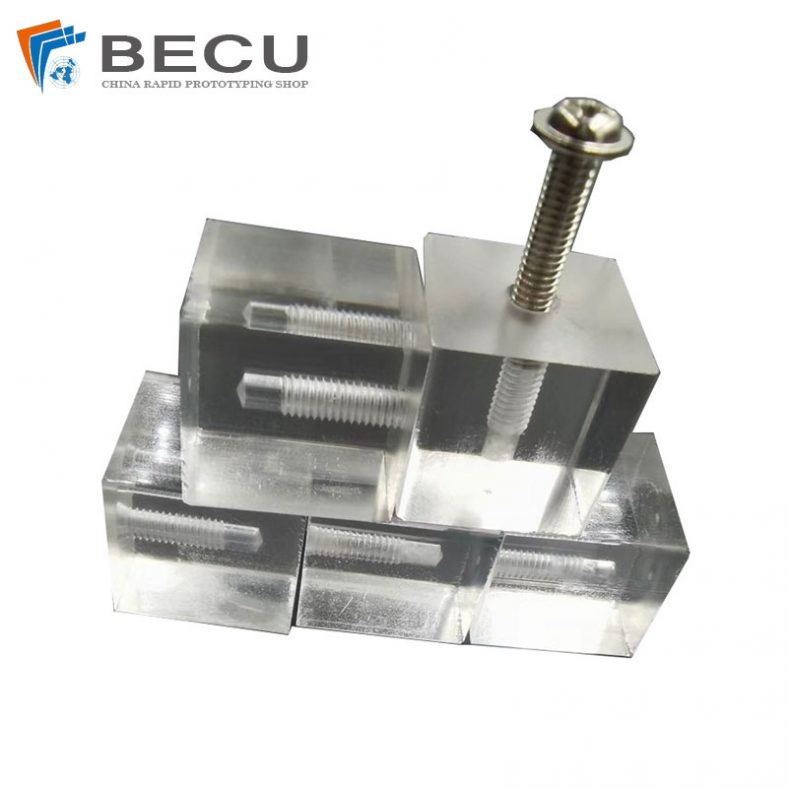

Acrylic, also known as PMMA (polymethyl methacrylate) or Plexiglas, Acrylic comes in different grades and colors. The choice of acrylic will depend on the project requirements—whether it’s transparent, colored, UV-resistant, etc,is a thermoplastic widely used in various industries due to its transparency, durability, and versatility.CNC machining for acrylic involves using computer numerical control (CNC) technology to precisely cut, carve, or mill acrylic material into desired shapes, sizes, and designs.

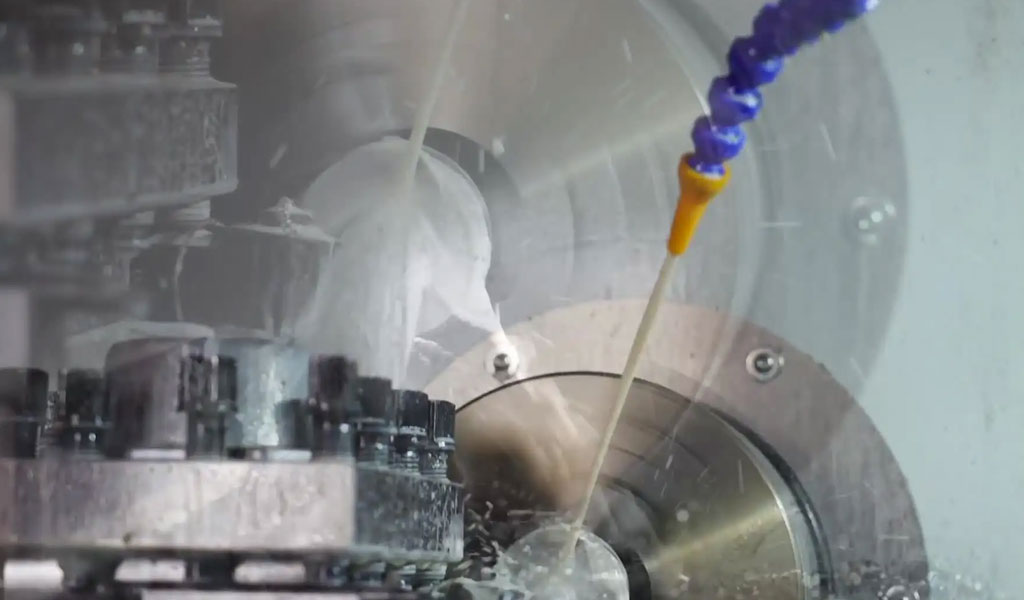

CNC machining is highly precise and efficient for acrylic, offering the ability to create intricate designs and achieve tight tolerances. However, it requires expertise in CNC programming, material properties, and machine operation to produce high-quality acrylic parts or products.

Be-Cu Prototype Inc has experienced CNC machinists or experts familiar with acrylic machining to optimize the process and achieve your desired results.

Aacrylic Cnc Machining Service – Custom CNC Plexiglass Parts Suppliers

If you’re looking for a readily available plastic with a high strength-to-weight ratio and good machinability, Plexiglass could be the right choice for your project.

Be-Cu Prototype Co. specializes in Acrylic CNC Machining(Acrylic CNC Milling,Acrylic CNC Turning and Acrylic 5 Axis Machining).

CNC Milling Acrylic

CNC milling acrylic refers to the process of using a computer numerical control (CNC) machine to precisely shape, carve, or cut acrylic material into specific designs, shapes, or parts.

- 3-axis CNC Milling: Produce the most common geometries and are best suited for designs that do not require multiple rotations of the acrylic block. Our 3-axis milling service are typically used to drill holes, mill slots, or machine previse edges.

- 4-axis CNC Milling: Allow access to an additional side of the acrylic block, allowing the milling of holes, slots, and other features to the side of a acrylic parts.

- 5-axis CNC Milling: Provide the highest precision and use multidimensional rotation to allow access to all sides of a acrylic block, allowing the creation of intricate details and complex designs.

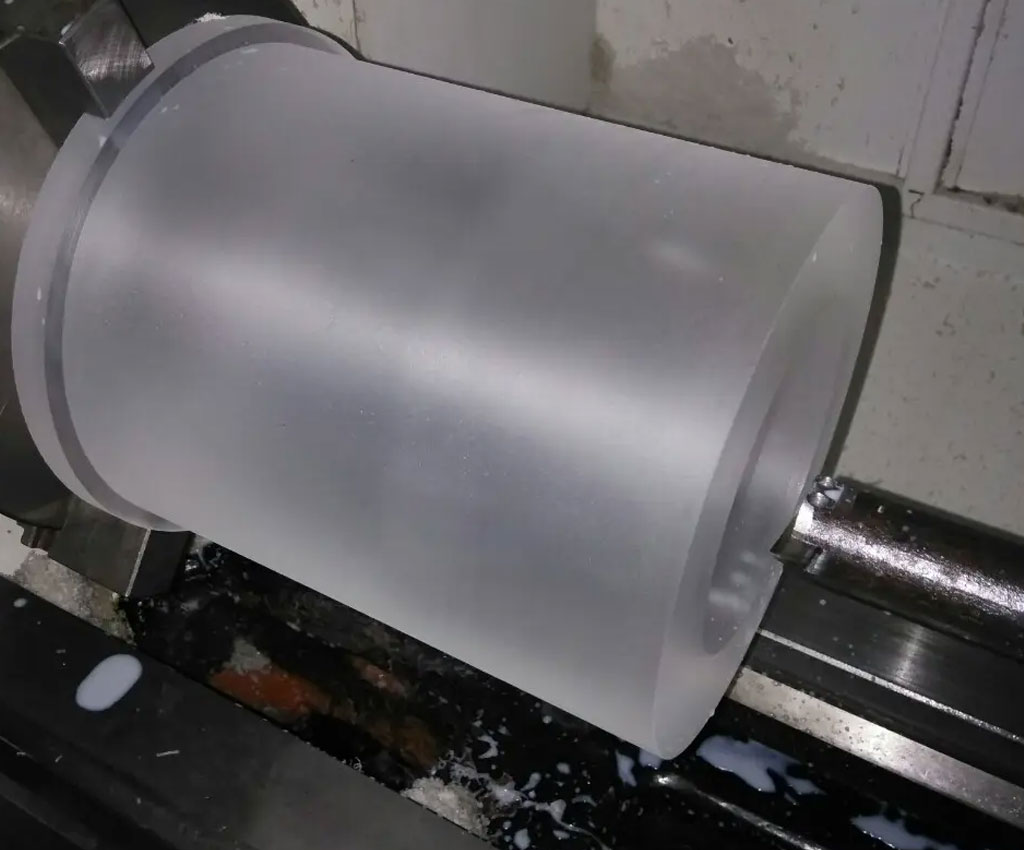

CNC Turning Acrylic

CNC turning acrylic refers to the process of using a computer numerical control (CNC) lathe machine to shape acrylic material into cylindrical or symmetrical parts by rotating the material against cutting tools.

- At Be-Cu Prototype Inc, we operate a full complement of Acrylic CNC turning equipment, ranging from basic 2- and 3-axis lathes to a revolutionary 5-axis mazak mill-turn center.

- The 5-axis mazak mill-turn center combines precision lathe with CNC mill to machine complex parts in a single setup. It makes unattended machining possible and significantly decreases lead times. Be-Cu is one of the only acrylic manufacturer that has an 5-axis mill-turn center. You will be hard-pressed to find and experience the benefits of this innovative technology anywhere else.

With over 30 years of engineering expertise we are dedicated to offering the highest quality Acrylic CNC machining and other products.

For your custom Acrylic CNC machining design, or reverse engineering, our exemplary service and efficient production ensures prompt deliveries coupled with outstanding service.

In addition to custom CNC Plexiglass Parts and reverse engineering we also provide emergency manufacturing and delivery, engineering, Plexiglass laser cut, PMMA Injection Molding and value-added manufacturing solutions.

Acrylic Grades We Work With

There are several grades and types of acrylic that are commonly used in various industries and applications. The choice of acrylic grade depends on the specific requirements of the project, considering factors such as transparency, impact resistance, UV stability, chemical resistance, and more. Some of the commonly used acrylic grades include:

CNC Machining Extruded Acrylic

CNC Machining Cast Acrylic

CNC Machining Impact-Modified Acrylic

CNC Machining Colored Acrylic

CNC Machining UV-Resistant Acrylic

CNC Machining Flame-Retardant Acrylic

When choosing an acrylic grade for CNC machining or any other application, it’s essential to consider the specific properties required for the project, including mechanical strength, optical clarity, weatherability, chemical resistance, and regulatory compliance if applicable.

Working with Be-Cu Prototype Inc who understands the different acrylic grades and their properties can help in selecting the most suitable material for your specific project needs. Additionally, testing prototypes or samples may be beneficial to ensure the chosen acrylic grade meets the desired performance criteria.

Advantages Of Acrylic Machining

- Great precision and high tolerance ensure high-quality Acrylic parts

- Time and cost-saving, great speed of Machining Acrylic part

- Allows products ordered to be made precisely to the specifications stated

- Complex Acrylic parts for high tech industry can be machined

Why Choose Our Acrylic Cnc Machining Service?

- Save time and money for your Acrylic project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of Acrylic grades and alloy materials can be machined

- Custom complex Acrylic machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Acrylic Cnc Machining Case Studies In China

Whether you require machined Acrylic prototypes or custom Acrylic parts for your electronic,led light,optics,automotive, aerospace applications or medical device component, we can easily help you. With our expertise in CNC Acrylic machining and the ability to integrate external combined processes, we can ensure the best performance for your machining Acrylic projects.Understanding the properties of different acrylic plastics, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on Acrylic Plastic. Be-cu prototyping company provides a range of solutions for the machining of Acrylic parts.