Polyoxymethylene(POM),also known as Delrin and Acetal,It is a linear polymer with no side chains, high density and high crystallinity. According to the different chemical structures in its molecular chain, it can be divided into two types: homopolyoxymethylene and copolyoxymethylene. The important difference between the two is: homopolyformaldehyde has high density, crystallinity, and melting point, but poor thermal stability, narrow cnc machining temperature range (about 10 °C), and slightly lower acid-base stability; The melting point and strength are low, but the thermal stability is good, it is not easy to decompose, the machining temperature range is wide (about 50 ° C), and the acid and alkali stability is good. Pom plastic material is an engineering plastic with excellent comprehensive properties. Pom plastic material has good physical, mechanical and chemical properties, especially excellent friction resistance.

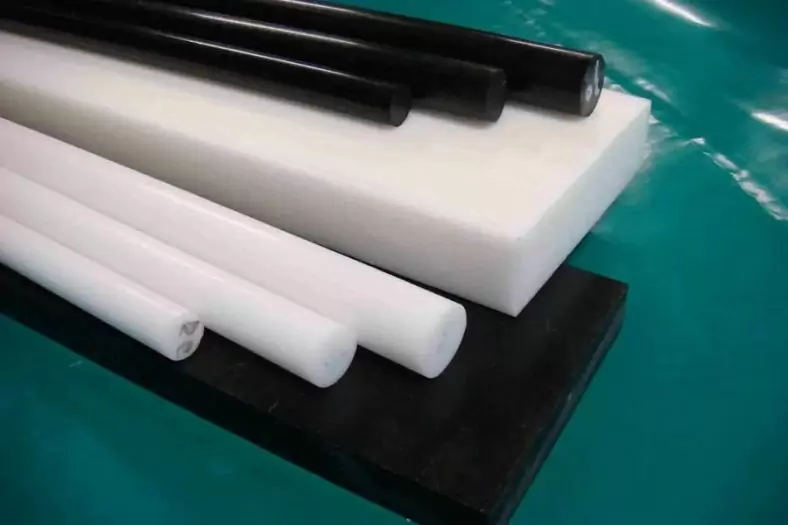

Commonly known as Saigang or Duogang, it is the third largest general engineering plastic.It is suitable for making wear-reducing and wear-resistant parts, transmission parts, as well as chemical, instrument and other parts.One of the synthetic resins, also known as polyoxymethylene resin, POM plastic, steel material, etc.; it is a kind of white or black plastic particles with high hardness, high rigidity and high wear resistance. Mainly used for gears, bearings, auto parts, machine tools, instrument internals and other products that play a role of skeleton.

Cnc Machining POM Parts – Polyoxymethylene Machined Services In China

Looking for reliable, quick-turn POM cnc machining services suppliers and CNC Machined product manufacturers?The pom plastic material has the best comprehensive properties, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance.The density of POM is 1.42g/cm3, which is much smaller than that of plastic ABS,good electrical insulation and it used in precision parts requiring high stiffness, low friction, and excellent dimensional stability.

Be-cu.com is plastic machining specialist of precision CNC machined plastic parts made from pom, delrin (POM-H),acetal and acetal Copolymer (POM-C). Capable of machining parts from 0.020 to 3 in. thickness and +/-0.003 in. tolerance. Methods include milling, turning,drilling, 3d printing,injection molding,sawing, grinding, boring, broaching, punching, reaming, shearing, sanding and tapping. Low to high volume and short to long run production available. Serves the aircraft, candy, communications, electrical, electronics, forklift, foodservice, medical, government, plating, power transmission, welding and military industries. AutoCAD and SolidWorks® files accepted.Manufacturing In China.

- POM 3D Printing: suitable for plastic parts with complex structure and low dimensional tolerance requirements, suitable for proofing or low-volume manufacturing. The most commonly used material is Delrin, Delrin 3D Printing is more popular.

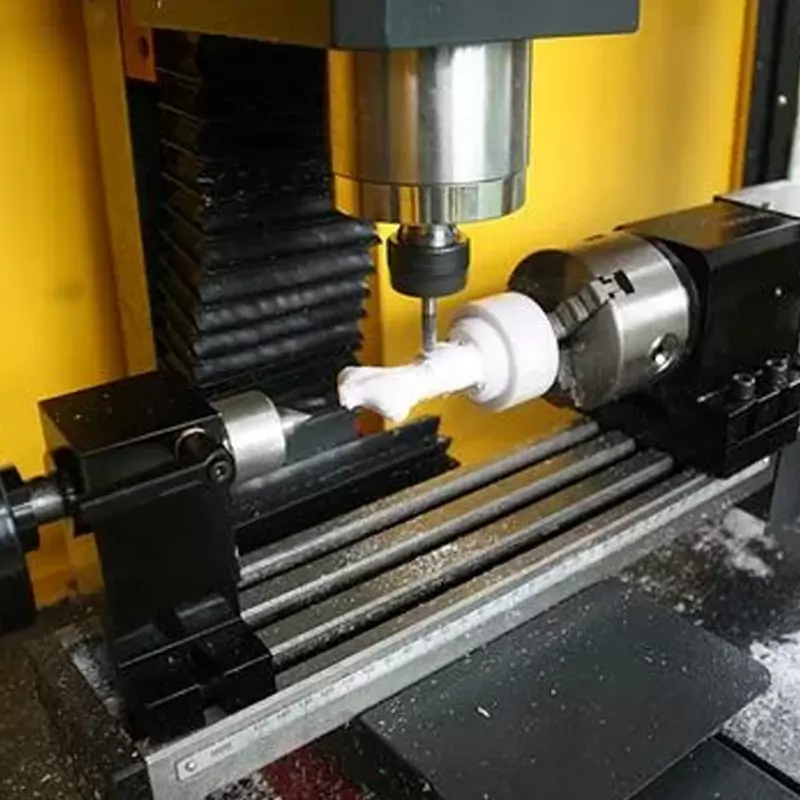

- POM CNC Milling: Part structure suitable for plastic sheets, processed by 3 aix milling, 4aix milling, and 5aix milling machines, suitable for proofing or low-volume manufacturing

- POM CNC Turning: Parts suitable for plastic rod or tube structures, processed by CNC lathes, suitable for proofing or low-volume manufacturing

- POM Injection Molding: suitable for simple structures, batches of plastic parts, using injection molding machines.

In addition to the cnc machining of POM plastic materials, Be-cu.com can also do other better materials for you, such as CNC Machining POM, the material POM can be replaced by other plastic, such as ABS, PC, PE, POM, Delrin, Nylon, Teflon, PP, PEI, Peek. Automation equipment, auto industry, hardware tool, mechanical accessories, equipment precision parts, medical device, cosmetics industry, aviation industry, industrial machines, automobile and other industries which machining parts are used etc..Whether it is a rapid prototype of a piece or a low-volume CNC manufacturer, we can help you solve quality and cost problems, provide your drawings and design solutions, and get a instant quotation within 4 hours. Ships within a week at the earliest.

How To Ensure POM Plastic Machining Accuracy?

Through a scientific/rigorous method and a non-impetuous mind

- The team members have 35 years of experience in plastic machining more than 100,000 precision products.

- Constant temperature cnc machining environment ●5-axis ultra-precision machining equipment, achieving 0.1μ resolution, 1μ cutting ●Equipped with ultra-high-precision Renishaw probe (on-line detection and compensation of parts during cnc plastic machining, so that the results can be seen before leaving the machine)

- Cooperate with global engineering plastics material suppliers to ensure the quality of raw materials

- ISO standardized management and evolving precision machining technology for special engineering plastics

- What can really achieve ultra-high precision for complex engineering plastic products is:

- Persistence in mission, love for the industry and not impetuous heart

Why Choose Our POM Cnc Machining Service?

- Save time and money for your POM project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of POM grades and plastic materials can be machined

- Custom complex POM machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top POM Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make POM prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making POM concept models and precise functional components. Understanding the properties of different pom plastic, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on POM. Be-cu prototyping company provides a range of solutions for the machining of pom plastic parts.