3D Printing For Nylon – What Is Nylon 3D Printing

The realm of 3D printing has continually evolved, introducing new materials and expanding the horizons of what’s possible in manufacturing and prototyping. Among these materials, nylon stands out as a versatile polymer, offering a plethora of benefits that make it a preferred choice in various industries.

Nylon, also known as polyamide, is a synthetic thermoplastic polymer characterized by its durability, flexibility, and resistance to wear and tear. Its suitability for 3D printing stems from its ability to produce robust, functional parts with excellent mechanical properties.

Typically, nylon filaments used in 3D printing processes are created through the extrusion of polyamide pellets, resulting in a material that offers high tensile strength and impact resistance.Be-Cu prototype provides nylon plastic 3D printing service with constantly high efficiency and quick turnaround. Advanced 3D printers and optimal materials allow us to ensure both cheap prices and premium quality.

Which Nylon Grade for 3D Printing

Several nylon grades commonly used in 3D printing include:

Nylon 12 3D Printing

Nylon 12 is valued for its exceptional impact strength, flexibility, and chemical resistance. It has a lower moisture absorption rate compared to Nylon 6 and Nylon 6/6, making it less prone to warping and dimensional changes due to moisture absorption. Nylon 12 is often used in applications requiring high durability and impact resistance, such as automotive and aerospace components.

- Density:1.3g/cm3

- Heat distortion temperature:150℃

- Tensile strength:47MPa

- Tensile modulus: 1900MPa

- Yield elongation :8%

- Elongation at break:19%

- Notched impact strength:8KJ/m2

- More

Nylon 6 (PA6) 3D Printing

Nylon 6/6 (PA66) 3D Printing

Glass-Fiber Reinforced Nylons 3D Printing

Carbon-Fiber Reinforced Nylons 3D Printing

Selecting the appropriate nylon grade for 3D printing depends on the specific requirements of your project, such as mechanical properties, thermal characteristics, chemical resistance, and intended application. Considerations like layer adhesion, printing temperature, warping tendencies, and post-processing requirements also play a significant role in choosing the suitable nylon grade for your 3D printing needs.

Nylon 3D Printing Service – 3D Printing Nylon Parts

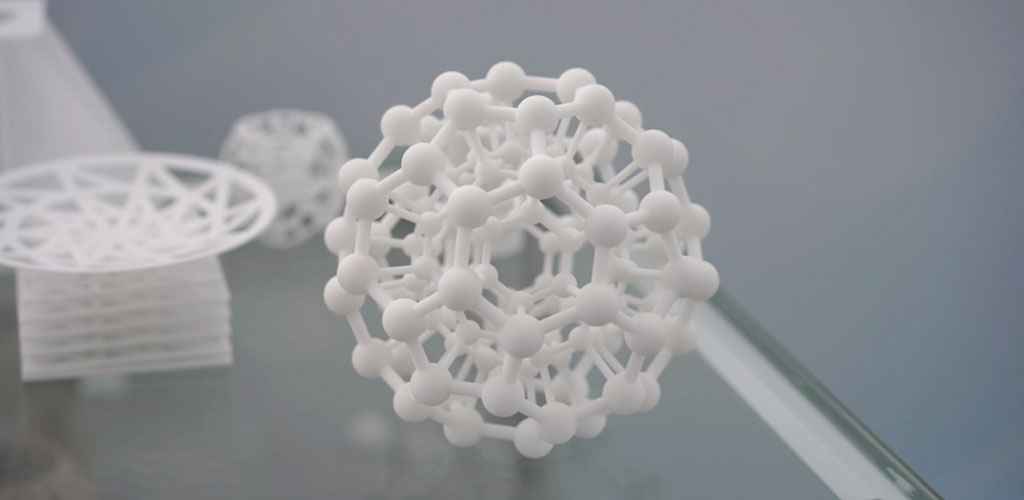

Nylon’s remarkable strength-to-weight ratio makes it an ideal choice for producing sturdy and resilient parts. Its ability to withstand stress and impact makes it suitable for functional prototypes, mechanical components, and end-use parts in various industries.It Is a realalteal alternative to injection molding and offers you absolute design freedom.

We produce your parts in Pa12 using FDM/SLS/HP Multi Jet Fusion 3D printing: the parts are therefore 100% solid and have no need for supports.From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. When it comes to 3D printing with nylon, choosing the right grade is essential as different grades of nylon offer distinct properties and characteristics suited for various applications. We provide nylon or polyamide (PA) materials to cater for various applications. Use nylon materials for prototyping and small batch production of functional parts.

| Material | Maximum Printing Size | Lead Time | Tolerance | Color | Distortion Temperature |

|---|---|---|---|---|---|

| PA12-White | 350*350*400mm | 48 or 72 Hours | ± 300μm or 0.3%mm | White | 145℃ |

| PA12-Black | 350*350*400mm | 48 or 72 Hours | ± 300μm or 0.3%mm | Gray-Black | 145℃ |

| PA12 Glass-filled | 330*330*380mm | 48 or 72 Hours | ± 300μm or 0.3%mm | Light-Grey | 160℃ |

| HP PA12 Black | 370*270*380mm | 48 or 72 Hours | ± 300μm or 0.3%mm | Black | 175℃ |

| HP PA12 Gray | 370*270*380mm | 48 or 72 Hours | ± 300μm or 0.3%mm | Gray | 175℃ |

Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our Nylon 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.

Advantages Of Nylon 3D Printing

- Outstanding mechanical properties

- Complex geometric structures

- Very resilient and durable material

- Easily post-processed in any color

- High chemical, heat and abrasion resistance

- Low cost

- MJF technology provides great balance between

Certifications & Quality Printing

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

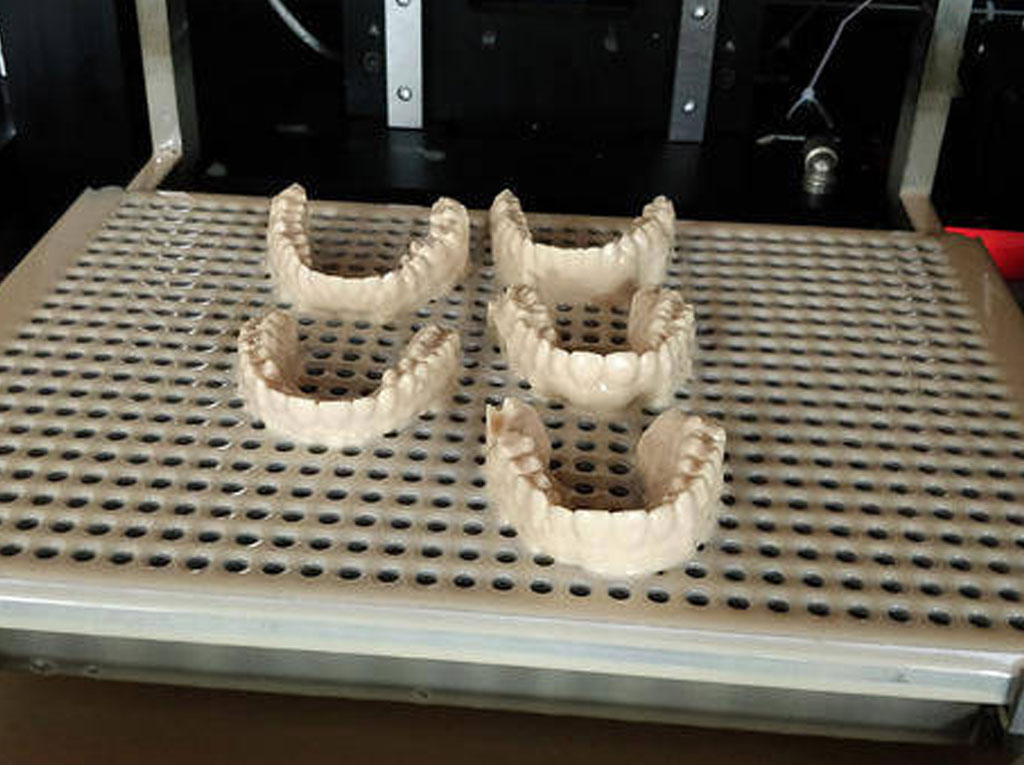

Top China Nylon 3D Printing Parts & Case Studies

The nylon 3D printer distributes even layers of plastics powder and the powdered nylon is selectively melted to previous layers, which allows 3D nylon parts to be fabricated of a bed of powdered plastics. Using nylon 3D printing allows us to produce parts with complex geometries that using traditional manufacturing methods not capable of and with materials that are difficult to process. 3D printing nylon materials including PA12,PA11, etc.

-

3D Printing Pool Pressure Cleaner Parts and Accessories

-

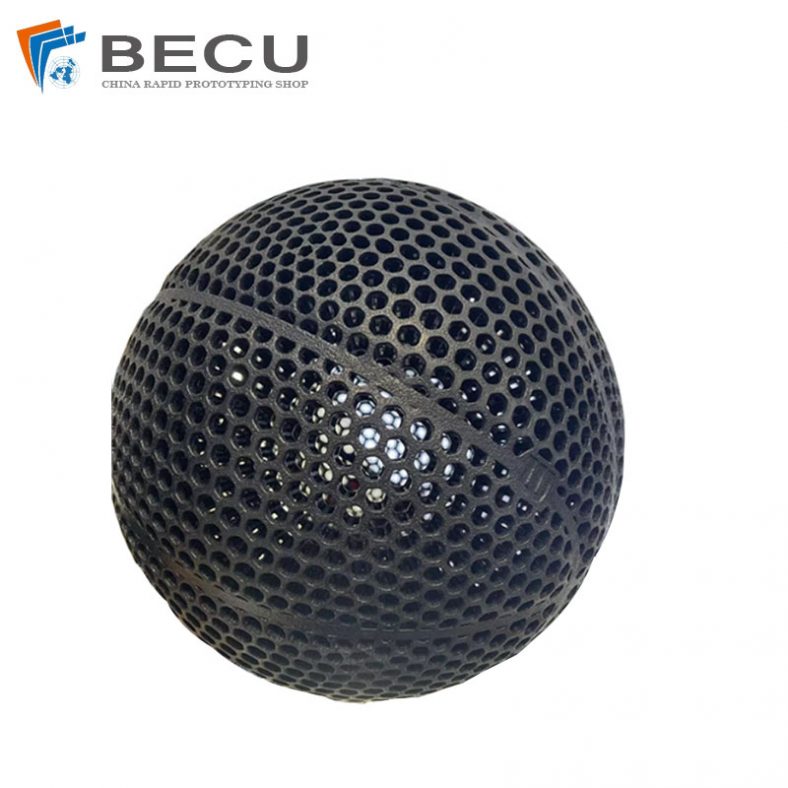

Nylon 3D Printed Size 5 Basketball

-

Black Nylon Medical Threaded Screw By MJF 3D Printing

-

MJF 3D Printing Black Nylon Red Dot Sighting For Medical

-

MJF 3D Printing Black Nylon Medical Arm Guards

-

3D Printed Octopus

-

SLA 3D Printing Black Panther Trophy By Spray Paint

-

Multi Jet Fusion Printed Nylon Plastic Parts

-

MJF 3D Printing Nylon 12 For Industrial Parts

-

MJF 3D Printing Handicraft Prototype

-

MJF 3D Printing Nylon 12 Prototype Parts

-

3D Printing Nylon Prototype Parts With Painted Surface

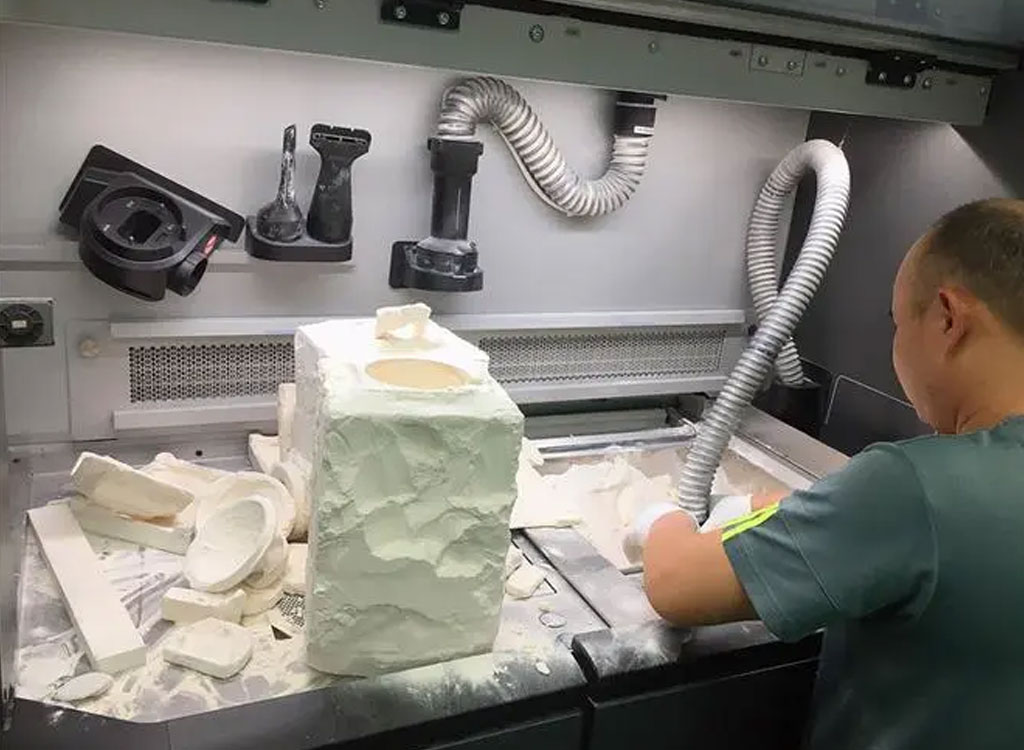

SLS 3D Printing For Nylon

The most commonly used nylons for SLS 3D printing are PA 11 and PA 12, but there are many more varieties. PA 11 powder is used for parts that require UV and impact resistance, while PA 12 is the first choice to enhance part strength and stiffness. In addition, there are reinforced PA powders, also known as nylon composite powders, which usually contain glass or carbon fiber particles in addition to nylon.

Some printers’ lasers are not powerful enough to print on all nylon materials. Be sure to check with your printer manufacturer about which materials can be used, because while some materials are generally acceptable, the results may not be as strong or flexible as promised unless printed on a certified machine.

SLS printers with open material systems can produce quality parts using a variety of materials from an equally wide range of manufacturers, so you have some choice when shopping. Closed system SLS printers can only use materials recommended by one manufacturer (usually the printer manufacturer’s recommended materials).

After printing, the part is completely wrapped in unsintered powder, which is also the support for the sintered part. Fortunately, with SLS technology, 50% to 70% of the green powder can be reused for future prints. From a sustainability perspective, this offers advantages over traditional manufacturing.

SLS printing is messy and requires equipment to “depowder” the parts and recycle the powder. SLS parts require only a small amount of post-processing, and their surfaces are usually matte and rough, which can be smoothed and are particularly suitable for dyeing.

Fused Deposition Modeling (FDM) For Nylon

FDM (3D printing using filament) is less suitable for nylon than SLS, but it can still produce strong and durable parts. In fact, FDM has advantages over SLS, including lower cost and less clutter.

The FDM 3D printing molding machine uses filament. The filament is melted and extruded in layers through the nozzle onto the molding platform until the part is formed. Not all FDM printers can handle nylon filament easily. It is important to have a good quality (all metal) hot end that can withstand temperatures above 250°C. In addition, nylon yarn is prone to warping, so adhesion to the bed surface is also a problem.

There are different types of nylon yarn, the most common ones are PA 6 and PA 66. Both products share the standard properties of nylon, namely strength, abrasion resistance and a low coefficient of friction, but have one big drawback: they are highly hygroscopic, so proper storage is key.

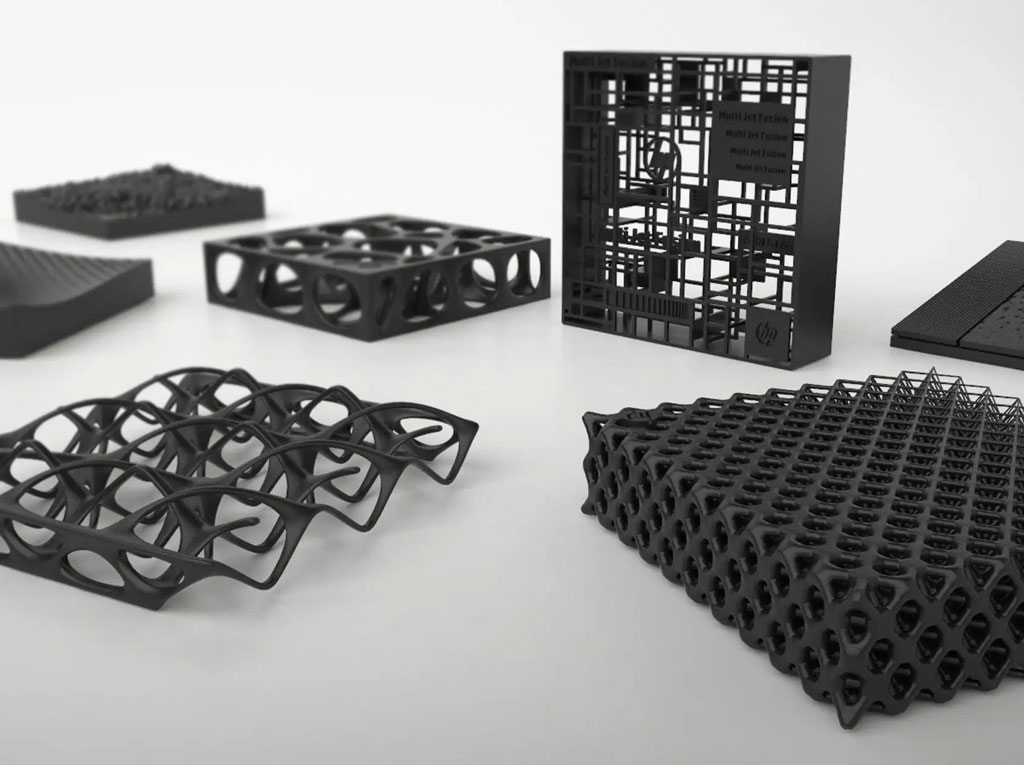

Multi-Jet Fusion (MJF) For Nylon

The HP Multi Jet Fusion 3D Printing Tips Box is a display piece printed in Nylon 12 and other nylon materials that showcases the various parts available with Multi Jet Fusion (Source: HP)

MJF is a unique powder-based 3D printing technology developed by HP. It’s similar to SLS, but also has a thing or two in common with binder jetting.In the Multi Jet Fusion process, radiation-absorbing ink is introduced into the powder bed via a print head. Areas that do not need to be printed are cooled using a second printing fluid, a thinning agent.

After each layer is printed, energy is directed into it using an infrared lamp. This process sequence is repeated until the entire structural volume of the job box is filled and the required parts within the powder bed are printed. Unlike other binder jet printing technologies, HP Multi Jet Fusion prints each new layer of materials and agents on top of the previous layer that is still molten, allowing the two layers to completely fuse to print directly from the powder bed. out of solid components.

While both technologies can print some amazing details on parts, MJF outshines SLS when it comes to printing detail. This is thanks in part to the detailing agent, which works by slightly reducing the melting potential energy at the edges of the part to make the edges as sharp as possible.

While the SLS may have an edge over the MJF when it comes to color options, that may be coming to an end with the arrival of the latest addition to HP’s MJF series, white nylon PA12. It has similar features and properties to standard PA12, including easy absorption of dyes, but is slightly more expensive.

After printing, you can recycle the unsintered powder, just like SLS. However, MJF can reuse more powder, even up to 80%. While this largely depends on the specific machines you compare, MJF machines are comparable in price to industrial SLS machines, but print times are faster and the detail may be greater.

HP isn’t the only 3D printer manufacturer to introduce heat into what appears to be a binder jetting process. Voxeljet has developed a technology called High Speed Sintering (HSS) in which a thin layer of plastic powder (such as PA 12) is applied to a heated building platform. The inkjet printhead then moves across the entire surface of the platform, wetting or penetrating various areas of the building platform with infrared light-absorbing ink. The building platform is then illuminated with infrared light, and the ink-jet areas absorb the heat, causing the underlying powder layer to sinter, while the un-ink-jet powder remains loose. The sintered parts cool in a controlled manner in the build area before being removed and unpacked. The HSS process, unlike the HP process, does not require a second printing fluid.

Online Cooperate With Nylon 3D Printing Company

We want you to have access to as many 3D printing materials as possible, so you can make the best choice for your project.Nylon is an ideal material for use in 3D printing.At Custom nylon 3D Printing, we rely on over a decade of experience to ensure we always exceed your expectations. We work with a variety of software files, including:

- MakerOS

- NetFabb

- AutoCAD

- Fusion 360

- HP SmartStream 3D.

Our default time-frame is 7 days, but we can turnaround a completed project within 48 hours in many instances. Our other capabilities include rapid prototyping, nylon cnc machining, laser engraving, vinyl cutting, and 3D modeling.

To learn more about what nylon 3D printing from Be-Cu company can do for you, and to begin your custom request, contact us via [email protected] today.