CNC machining Bakelite refers to the process of using Computer Numerical Control (CNC) machines to shape, cut, and mill Bakelite material into precise and intricate components. Bakelite is a type of synthetic thermosetting plastic that was one of the first plastics to be used in industrial applications. It is known for its excellent electrical insulating properties, mechanical strength, and heat resistance.At Be-Cu.com, we have always been dedicated to pushing the boundaries of CNC machining technology. With the rapid evolution of industries and their increasing demand for intricately designed components, we recognized the need to enhance our service portfolio. This realization led us to develop the Bakelite CNC Machining Service, a specialized solution designed to cater to the unique properties and applications of Bakelite Parts.

Machining Bakelite Service – Cnc Machining Bakelite Parts

Bakelite, renowned for its outstanding electrical insulation capabilities and mechanical strength, has secured its place in a wide range of industries, from electronics to automotive and beyond. Our Bakelite CNC Machining Service takes this versatile material to new heights, delivering precision-engineered components that meet the most exacting requirements.

What sets our Bakelite CNC Machining Service apart is a fusion of cutting-edge technology and a team of skilled experts. Our state-of-the-art CNC machinery operates with micron-level accuracy, ensuring that every cut, contour, and detail is executed flawlessly. Our technicians, armed with years of experience in CNC machining and a deep understanding of Bakelite, optimize machining parameters to guarantee the highest quality results.

Customization lies at the heart of our service. We understand that each project comes with its unique challenges and design specifications. Our engineering team collaborates closely with our clients, transforming their ideas into tangible components that exceed expectations. This level of partnership ensures that every piece leaving our facility not only meets industry standards but also embodies the vision of our clients.

With our Bakelite CNC Machining Service, we are poised to cater to a diverse range of industries. Whether you require Bakelite insulators, connectors, or specialized components, we have the expertise and technology to deliver outstanding results that drive your projects forward.

I invite you to connect with us to discuss how our Bakelite CNC Machining Service can elevate your projects to new heights. We are excited to explore the endless possibilities that this development brings and look forward to collaborating with you to shape the future of precision engineering.

Thank you for your time and consideration. We eagerly anticipate the opportunity to showcase the capabilities of our Bakelite CNC Machining Service and demonstrate how it can meet and exceed your expectations.

Bakelite Machining Properties

The table below displays an overview of the material properties, units and values for machining bakelite.

| Property | Description and Value |

|---|---|

| Material | Bakelite (Phenolic Resin) |

| Density | 1.3 – 1.5 g/cm³ |

| Hardness | Rockwell M 60 – 100 |

| Tensile Strength | 40 – 80 MPa (5800 – 11600 psi) |

| Compressive Strength | 110 – 140 MPa (16000 – 20300 psi) |

| Flexural Strength | 90 – 140 MPa (13000 – 20300 psi) |

| Impact Strength | 1 – 10 kJ/m² (0.48 – 4.76 ft-lb/in²) |

| Thermal Conductivity | 0.2 – 0.6 W/(m·K) |

| Electrical Insulation | Excellent |

| Thermal Expansion | 60 – 80 x 10^-6/°C (33.3 – 44.4 x 10^-6/°F) |

| Operating Temperature Range | Up to 150°C (302°F) |

| Machinability | Good |

Do you have specific bakelite cnc machining requirements? Feel free to get in touch with our Bakelite machining experts to discuss the use of bakelite plastic to machine your parts for industrial applications. Our experts will respond to you at the earliest.

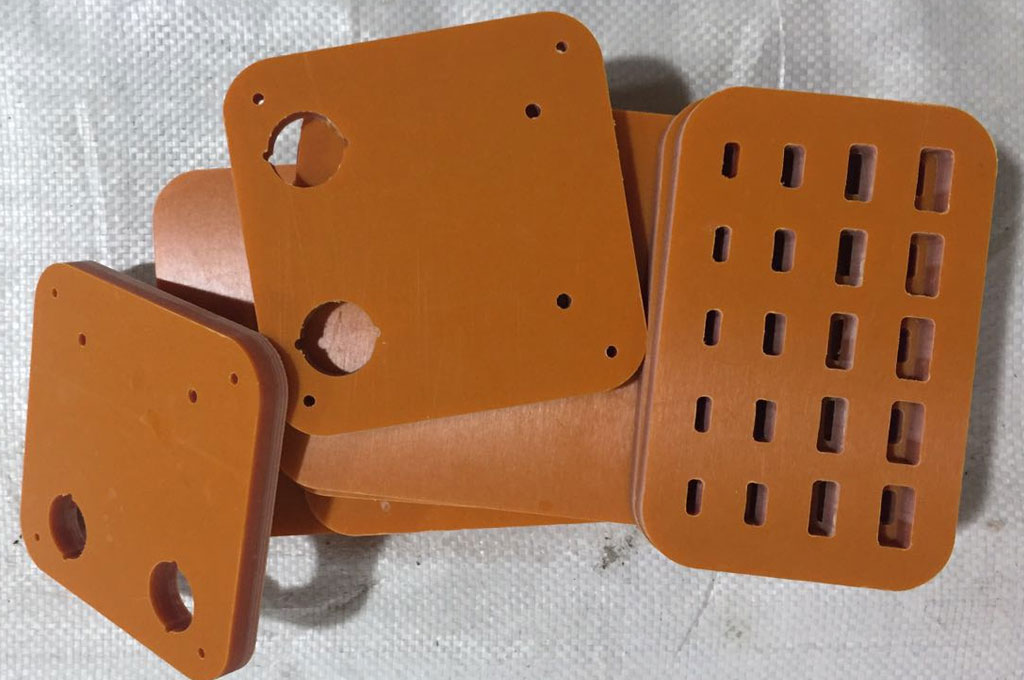

Bakelite Jig And Fixtures

Bakelite jigs and fixtures play a pivotal role in the manufacturing process, particularly in CNC machining and other precision operations. These specialized tools are designed to securely hold workpieces in place, guide machining tools, and ensure accurate and repeatable production.

Bakelite Jigs

A jig is a device used to hold and guide a workpiece during machining or assembly operations. In CNC machining, a Bakelite jig is used to position and secure the Bakelite workpiece in the correct orientation for precise cutting, drilling, and shaping.

Jigs often include features like slots, holes, and clamps to hold the workpiece firmly while allowing the machining tools to access specific areas.

Bakelite Fixtures

A fixture is similar to a jig but is more complex and versatile. A Bakelite fixture not only holds the workpiece but also provides precise positioning and alignment for multiple machining operations.

Fixtures are especially useful for batch production or when multiple operations need to be performed on a single workpiece without repositioning.

How To Ensure Bakelite Plastic Machining Accuracy?

Through a scientific/rigorous method and a non-impetuous mind

- The team members have 35 years of experience in plastic machining more than 100,000 precision products.

- Constant temperature cnc machining environment ●5-axis ultra-precision machining equipment, achieving 0.1μ resolution, 1μ cutting ●Equipped with ultra-high-precision Renishaw probe (on-line detection and compensation of parts during cnc plastic machining, so that the results can be seen before leaving the machine)

- Cooperate with global engineering plastics material suppliers to ensure the quality of raw materials

- ISO standardized management and evolving precision machining technology for special engineering plastics

- What can really achieve ultra-high precision for complex engineering plastic products is:

- Persistence in mission, love for the industry and not impetuous heart

Why Choose Our Bakelite Cnc Machining Service?

- Save time and money for your bakelite project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of bakelite grades and plastic materials can be machined

- Custom complex bakelite machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

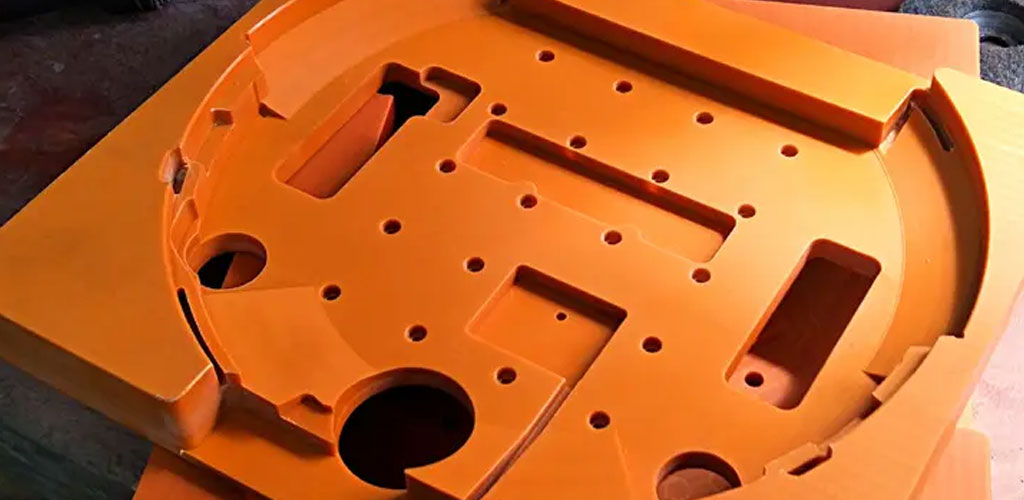

Top Bakelite Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make bakelite prototypes.Our company has rich experience making bakelite concept models and precise functional components. Understanding the properties of different bakelite plastic, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on bakelite. Be-cu prototyping company provides a range of solutions for the machining of bakelite plastic parts.