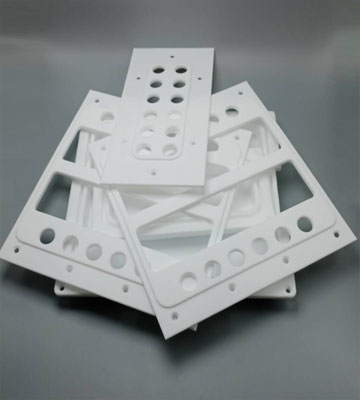

Polytetrafluoroethylene (PTFE), commonly known as the Teflon™, is a high molecular polymer obtained by polymerizing tetrafluoroethylene as a monomer that can be used in a range of applications, can be easily machined to any form that you desire. This makes it a popular choice of material for producing parts featuring intricate designs and complex geometries.PTFE is white waxy, translucent, excellent in heat resistance and cold resistance, and can be used for a long time at -180 to 260ºC. At BE-CU.com, we specialize in customized PTFE/Teflon parts machining and fabrication services for industrial applications. Our vast industrial experience coupled with our technical knowledge and manufacturing expertise has helped us build quality teflon machined parts.Be-cu.com is your #1 source for high precision Teflon™ machining. Request a quote on your project or contact us today to get started.

Cnc Machining Teflon Parts – PTFE Machined Services In China

Looking for reliable, quick-turn teflon cnc machining services suppliers and CNC Machined product manufacturers?

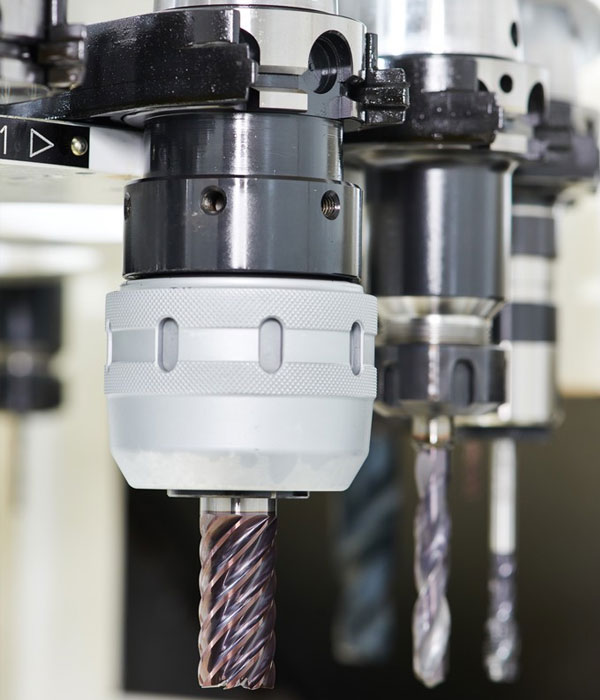

Using teflon materials (chemically known as Polytetrafluoroethylene) is ideal for a wide spectrum of CNC machining applications where thermal, chemical, and combustion properties are critical to performance.BE-CU.COM is experienced expert for precision cnc machining teflon parts.Our Precision PTFE CNC machining services include milling, boring, drilling, tapping, EDM, routing, rolling, routing, laser cutting, waterjet cutting, facing, threading, reaming, taper turning, tapping, knurling, gear hobbing, broaching, cutting, counterboring, countersinking. Secondary operations include assembly, centerless grinding, heat treating, polishing, electroplating, powder coating and welding.

ISO 9001:2015 certified machining services for PTFE. Machining capabilities include 7-axis, CNC, single spindle, Swiss screw, continuous, dial transfer, high speed, high velocity, in-line, and rotary transfer machining. Capable of manufacturing parts with maximum dimensions of 24″ L x 12″ W x 12″ H, a 2.5″-6″ diameter, and tolerances of +/-.0001″. Prototype and low to high volume production offered. Suitable for cabling and electrical insulators, semiconductor components, capacitors, non-lubricating bearings, O-rings, seals, gaskets, bushings, bearings and gears. Serves the aerospace, appliance, automotive, chemical, communications, cosmetics, electrical, marine, medical, mining, packaging, plumbing, optical, retail, telecommunications, textile, transportation and wastewater industries. CAD and CAM files accepted.

How To Ensure PTFE Plastic Machining Accuracy?

Through a scientific/rigorous method and a non-impetuous mind

- The team members have 35 years of experience in plastic machining more than 100,000 precision products.

- Constant temperature cnc machining environment ●5-axis ultra-precision machining equipment, achieving 0.1μ resolution, 1μ cutting ●Equipped with ultra-high-precision Renishaw probe (on-line detection and compensation of parts during cnc plastic machining, so that the results can be seen before leaving the machine)

- Cooperate with global engineering plastics material suppliers to ensure the quality of raw materials

- ISO standardized management and evolving precision machining technology for special engineering plastics

- What can really achieve ultra-high precision for complex engineering plastic products is:

- Persistence in mission, love for the industry and not impetuous heart

Why Choose Our PTFE Cnc Machining Service?

- Save time and money for your PTFE project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of PTFE grades and plastic materials can be machined

- Custom complex PTFE machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top PTFE/Teflon Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make PTFE prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making PTFE concept models and precise functional components. Understanding the properties of different teflon plastic, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on ptfe. Be-cu prototyping company provides a range of solutions for the machining of teflon plastic parts.

What Is Teflon – The Basic Information Of Polytetrafluoro-Ethylene

Polytetrafluoroethylene (PTFE) is commonly known as the king of plastics. It is a polymer compound formed by addition polymerization of tetrafluoroethylene. There are three kinds of granular, powder and dispersion. The density of the solid is 2.25g/cm3. White color, translucent, good heat resistance. The operating temperature can be between -75°C and 250°C. When heated to 415 ℃, it can be decomposed and the generated gas is harmful to human beings. It does not react with all chemicals except molten metal sodium and liquid fluorine. In chemical production, it is used as equipment lining, fractionation tower, bellows, pumps, valves, gaskets, etc.; in the machinery industry, it is used as seals, piston rings, rotating bearings, etc.; Wire insulation, cable insulation, high-frequency electronic instrument insulation and the manufacture of high-frequency cables, high-precision capacitors, wires, etc.; in the construction industry, used to make large pipes, steel structure roof trusses, bridges, etc.; in the textile industry, it can be used as an anti-stick roller In the pharmaceutical industry, it is used as artificial blood vessels, artificial heart-lung devices, disinfection protectors, etc.; in the plastic and food industry, it is used as a release agent. In 1935, when R.J. Plaquette was studying the refrigerant of halothane, he found that when the container was filled with tetrafluoroethylene, a white solid appeared on the wall of the container, which was the first discovery of polytetrafluoroethylene. In 1941, the DuPont Company of the United States conducted a pilot test, and industrial production began in 1950.

The Property Of Polytetrafluoro-Ethylene

Suspension PTFE is white, odorless, tasteless, non-toxic powder, with relative density of 2.1 to 2.3, glass transition temperature of 327 °C, thermal decomposition temperature of 415 °C, excellent high and low temperature resistance, and can be used in – Long-term use at 250~260℃. It is easy to decompose and release toxic gas above 400℃. It has excellent electrical properties and is not affected by working environment, humidity, temperature and frequency. It has good arc resistance, but poor corona resistance. Ol。 Good lubrication performance, has a very low coefficient of dynamic and static friction, the coefficient of friction to metal is as low as 0.07, and its own coefficient of friction is as low as 0.07. The non-stick surface is more prominent, and almost all sticky substances cannot adhere to its surface. The wetting properties of water and many organic solutions are very poor. Has excellent resistance to atmospheric aging and non-flammability. The performance remains unchanged after long-term exposure to the atmosphere. Under normal conditions, PTFE is completely non-flammable. Excellent chemical stability. Except for elemental fluorine and molten metal sodium, which have a certain corrosive effect on its products, almost all strong acids, strong bases, strong oxidants and organic solvents do not work on it, so it is known as “the king of plastics”. Adding different fillers to PTFE, such as graphite, copper powder, molybdenum disulfide, glass fiber, carbon fiber, polyphenylester, etc., the performance of the obtained filling product is greatly improved compared with that of pure PTFE. The use of PTFE fillers in various application fields is extremely common and can widely meet the special requirements of users. Filled products with different formulations have different properties. Some load-resistant deformation can be increased by 5 times, thermal conductivity can be increased by 5 times, hardness can be increased by 10%, compressive strength can be increased by 2 to 3 times, wear resistance can be significantly improved, and linear expansion coefficient can be reduced. 30% to 50%.

- Melting point: 327 °C

- Boiling point: 400 °C

- Density: 2.15 g/mL at 25 °C

- Refractive index: 1.35

- Solubility: Solubility in water:

- Form: powder

- Color: white

- Specific gravity: 2

- Water solubility: Insoluble in water. Soluble in perfluoro kerosene.

- Merck: 14,7562

- Stability: Stable – unreactive with most materials. Incompatible with molten alkali metals, fluorine and other halogens, strong oxidizing agents.

Teflon – Properties – Forming

Polytetrafluoroethylene is a straight-chain thermoplastic polymer in terms of molecular structure, but even at a temperature below the crystallization transition point (327 ° C), it can only form a non-crystalline gel state, and the melt viscosity is as high as 1010 ~ 1011Pa. s, cannot flow, so it is difficult to use thermoplastic processing methods to form, and it is necessary to use a processing method similar to “powder metallurgy” – a combination of cold pressing and sintering. Usually, the powdery resin is first cold-pressed in a mold at a pressure of 20-30MPa, then sintered at 370-380°C, and then cooled and shaped to make plates, rods, sleeves, gaskets, parts, filling products and Rough etc. The blanks are then machined into various parts, sheets and non-oriented films. The non-oriented film can also be calendered into an oriented film or wrapped and bonded to make a sandwich gasket and other products. A pore-forming agent (such as sodium sulfate or sodium chloride, etc.) is mixed into the polytetrafluoroethylene resin. After cold pressing and sintering, the pore-forming agent is removed to obtain a porous blank or product. Porous blanks can be turned into porous films or sheets.

1.High Chemical Stability

PTFE can withstand the action of all strong acids, strong bases, strong oxidants, reducing agents, etc. except for molten alkali metals, fluorine elements, strong fluorinated media, and sodium hydroxide above 300 °C. Its chemical corrosion resistance exceeds that of precious metals, glass, ceramics, enamels and alloys, etc. Even uranium fluoride, which is a strong corrosive agent in the atomic energy industry, does not corrode it.

2.Wide Operating Temperature Range

PTFE can be used in a wide area of -250 to 260 °C, and can maintain a certain degree of flexibility even at an ultra-low temperature of -260 °C; at 260 °C, its breaking strength still remains about 5MPa (about 1 at room temperature). /5), the yield strength reaches 1.4MPa.

3.Prominent Non-Stick

PTFE is a solid material with the smallest surface energy at present. The surface tension is only 0.019N/m. Almost all solid materials cannot adhere to its surface. Only liquids with surface tension below 0.02N/m can completely infiltrate its surface.

4.Abnormal Lubricity

Because the mutual attraction between PTFE macromolecules is small, and the attraction of the surface to other molecules is also small, its friction coefficient is very small, and it is the self-lubricating material with the lowest friction coefficient found so far.

5.Excellent Electrical Insulation Properties

PTFE is a highly non-polar material with excellent dielectric properties and excellent arc resistance. During high voltage discharge, only some cracked non-conductive gas is released without carbonization causing short circuit.

6.Excellent Aging Resistance And Radiation Resistance

There is no photosensitive group in the PTFE molecule, so it is not only dimensionally stable at low temperature and high temperature, but also has the same performance in harsh environments, and is not attacked by microorganisms in a humid state, and has extremely high protection against various ray radiations.

7.Minimal Water Absorption

The water absorption rate of PTFE is generally about 0.001% to 0.005%, and its permeability is also low.

The Production Method Of Teflon

The purified tetrafluoroethylene monomer is polymerized in an enamel or stainless steel polymerization kettle with water as a medium, ammonium persulfate as an initiator, sulfite reducing agent, and hydrochloric acid as an activator. The operating pressure is 0.6-0.8MPa, the operating temperature is 10-50°C, and the reaction time is 2-3h to obtain a polymer, which is then smashed, ground, washed and dried to obtain a powdery suspended polytetrafluoroethylene resin product.

Teflon – Structure And Characteristics

- In PTFE, fluorine atoms replace the hydrogen atoms in polyethylene, because the larger radius of fluorine atoms is (0.064nm), which is larger than the radius of hydrogen atoms (0.028nm), and the negative charge of fluorine atoms of adjacent macromolecules They repel each other, so that the C-C chain is gradually twisted from the flat, fully stretched tortuous conformation of polyethylene to the helical conformation of PTFE, and forms a tight and completely “fluorinated” protective layer, which makes it unmatched by other materials. Chemical stability and low cohesive energy density.

- The bond energy of the C-C bond is 372kJ/mol, and the bond energy of the C-F bond is 347kJ/mol, which are the strongest among the known bond energies, so the intramolecular bond is firm, the heat resistance is high, and the long-term use temperature It is -250℃~260℃, and the bond length of C-C bond is 1.54×10-10m, and the bond length of C-F bond is 1.41×10-10m, which is also the shorter of common single bonds, so the chemical properties Stable, difficult to react chemically with other substances, showing excellent weather resistance, stain resistance and chemical resistance.

- There are no branches on the main chain of macromolecules, and no cross-chains are formed in the whole, so the molecular outline is smooth, and the TFE monomer has perfect symmetry, which makes the attraction and surface energy between PTFE molecules low, so PTFE has Very low surface friction coefficient, and easy to transfer to the dual surface during the sliding process to form a thin transfer film.

The Application Of Teflon Plastics

PTFE has excellent high and low temperature performance and chemical stability, good electrical insulation, non-adhesion, weather resistance, non-combustibility and good lubricity. It is used in the aerospace field to a wide range of daily commodities and has become a modern science and technology. It is an indispensable material for solving many key technologies in military industry and civilian use.

Suspension PTFE (named as general-purpose molded PTFE resin in domestic standards) has a wide range of applications. In the chemical industry, it is suitable for use as chemical equipment lining; pipes, fittings and valve linings; pumps, heat exchangers, fractionation towers, bellows, sealing gaskets and sealing packings, etc. In the machinery industry, it can be used as mechanical seals, piston rings, rotating bearings, etc. The mechanical dynamic seal ring or static seal ring made of it can be combined with ceramic ring, high silicon iron ring or hard alloy ring to form a mechanical seal friction part. Can also be used as auxiliary seals such as O-rings and V-rings. Filled PTFE products made by adding glass fiber, graphite, bronze powder or molybdenum disulfide have good lubricity and wear resistance, and overcome the disadvantage of large creep. In the electrical and electronic industry, it can be used as wire, cable insulation, high-frequency cable, flexible cable, motor groove, high-precision capacitor, tube socket, various parts and connectors, electronic computer signal wire insulation, printed circuit board, etc. . In the construction industry, it is used as bridges, tunnels, steel structure roof trusses, large pipelines, storage tanks, and even highways and displacement bearing sliders. In the textile industry, it is used as an anti-stick roller, a reciprocating part, and a conveyor belt impregnated with PTFE. It is used as a mold release agent in the food industry.

1.The Application In Anti-Corrosion And Wear-Reduction

According to the relevant statistics of developed countries, the economic loss caused by corrosion in today’s industrialized countries accounts for about 4% of the gross national economic output value. A considerable number of accidents in chemical production are caused by chemical reactions caused by equipment corrosion and medium leakage. It can be seen that the loss caused by corrosion is a serious problem, and it has attracted widespread attention. PTFE material overcomes the shortcomings of ordinary plastics, metals, graphite, ceramics, etc., such as corrosion resistance and poor flexibility. With its excellent high and low temperature resistance and corrosion resistance, it can be used in harsh conditions of temperature, pressure and medium. It has become the main corrosion-resistant material in petroleum, chemical, textile and other industries.

PTFE pipes are mainly used as delivery pipes and exhaust pipes for corrosive gases, liquids, vapors or chemicals. The push tube formed by PTFE dispersion resin is lined into the steel pipe to form a lining, or the PTFE push tube is wound with glass fiber for reinforcement, or the PTFE push tube is woven and wound with steel wire to be reinforced, and the liquid medium can be transferred under high pressure. It is an indispensable part of hydraulic transmission, and can greatly improve the rupture strength at high temperature and has good bending fatigue resistance.

Because the friction coefficient of PTFE material is the lowest among known solid materials, this makes filled PTFE material the most ideal material for oil-free lubrication of mechanical equipment parts. For example, adding lubricating oil to equipment in industrial fields such as papermaking, textiles, and food can easily contaminate products, so filling PTFE materials solves this problem. In addition, experiments have shown that adding a certain amount of solid additives to engine oil can effectively save about 5% of engine fuel oil.

2.Corrosion-Resistant Sealing Material

Another major application of PTFE in chemical industry is sealing material. Due to its good comprehensive properties, PTFE is unmatched by any sealing material. It can be used for sealing in various harsh occasions, especially when high temperature and corrosion resistance are required.

PTFE raw material tape has long fiber, high strength, large plasticity and good calendering ability. It can be completely sealed by applying a small pressing force. It is easy to operate and apply, and it is more efficient when used on uneven surfaces or precise structures. , has good sealing performance and can improve corrosion resistance, expand its scope of use.

The sealing of sliding parts uses PTFE packing, which can obtain good corrosion resistance and stability, and it has a certain compressibility and resilience, and has low sliding resistance. Filled PTFE sealing material has a wide temperature range and is the main substitute for traditional asbestos gasket materials. It also has high modulus, high strength, creep resistance, fatigue resistance, high thermal conductivity, low thermal expansion coefficient and friction coefficient, etc. Performance, adding different fillers can expand the scope of application.

3.Anti-Stick Application

PTFE material has the smallest surface tension among solid materials, does not adhere to any substance, and also has excellent characteristics of high and low temperature resistance and non-toxicity, so PTFE is often used as a coating as a non-stick lining for tableware, mainly for non-stick pans and The inner pot of the microwave oven.

In the textile industry, a large number of chemical sizing is used for sizing of yarn, especially when using styrene-butadiene milk, acid methyl cellulose, polyvinyl acetate and other very viscous sizing as the sizing, serious sticking roll phenomenon will occur. It is necessary to remove the sticky scars to continue production, which not only increases the labor, but also reduces the production efficiency and affects the product quality. After using the PTFE sticking roller, the anti-sticking effect is remarkable. Similarly, it can also be applied to various plastics. Packaging and sealing machinery.

4.Electrical Applications

The inherent low loss and dielectric constant of PTFE make it an ideal insulating material for wire and cable. Reasons why PTFE is used as wire coating: It has excellent electrical properties, its volume resistivity can reach 1017Ω, its surface resistivity is greater than 1016Ω, and it remains unchanged under 100% relative humidity; the dielectric constant is as low as 2.0, and the dielectric The electrical loss tangent is about 2 × 10-4 and has nothing to do with temperature and frequency; good heat resistance, long-term use at 260 ° C, good insulation, can reach H level or above; strong toughness and flexibility, even low Toughness is still not affected to -90 ℃; aging resistance, excellent weather resistance, high chemical stability; non-flammable and low smoke. Printed circuit substrates made of it have been widely used in the aerospace field, so PTFE products are especially suitable for many high-performance and challenging fields such as telecommunications, computers, testing and measurement, and national defense.

5.Construction Applications

With the development of domestic and foreign economies, many cultural and entertainment facilities have used it as a roof material in the construction, which has long been widely used abroad. The first building using this material was built in California in the 1970s. In the past two years, it has also been used in China, such as: Shanghai 80,000 people stadium, roof of Hongkou Stadium, Oriental Pearl Tower, Beijing Olympic Bird’s Nest, etc. PTFE as a building membrane material has a durability of more than 20 years (now commonly used high-decorative, high-weather-resistant acrylic polyurethane coatings, acrylic silicone coatings and silicone coatings, its durability is generally 5 to 10 years, and silicone poly Ester paint is only 10 to 15 years at most); and its self-cleaning property is good, it does not absorb dust and dirt, and rainwater can wash off the surface attachments, which can reduce the cost of painting and cleaning, so it is suitable for occasions with high cleanliness requirements. .

6.Medical And Health Applications

A variety of polymer products are widely used in modern medicine, which greatly excludes and replaces the application of metals and other materials in the medical field. These products are not only used in the human body and in contact with human body tissues, but also in various devices in the medical field. In recent years, the polymer PTFE has good flexibility and biocompatibility, and is gradually becoming an important part of biofunctional materials.

PTFE has low surface tension, non-hydrophilicity and good biocompatibility, and can be used in artificial blood vessels. The increase in the surface potential energy of the artificial blood vessel wall will promote the sedimentation and coagulation of endothelial cells, which is the change of the surface energy of microporous PTFE products. Leads to a pronounced biological response to the surrounding tissue, exploiting this property to prevent thrombotic processes in the graft space. The gastroscopic forceps catheter is composed of expanded PTFE and rubber plastic film. Because it can be bent and deformed at will, it has no foreign body reaction when it comes into contact with the human body. It is used for instant sampling of the human stomach, foreign body extraction, polyp removal, etc. The patient is spared unnecessary suffering.

In addition, polyPTFE can be made into artificial cruciate ligament, joint, esophagus and trachea, urethra, bile duct, etc. in medicine. It can also be used for plastic surgery, bone tissue replacement, promotion of fracture healing, skin or organ transplantation, periodontal tissue regeneration, etc.

7.Other Applications

PTFE also has many applications, such as using its membrane with porosity, as a filter material, it can selectively permeate gas or liquid, and it is used for gas-liquid separation, gas-gas separation and liquid-liquid separation. Carbon black pressure can also be used to make heating elements, such as the middle heating layer of electric blankets.