ABS machining refers to the process of using machining techniques to shape, cut, or otherwise modify parts made from ABS (Acrylonitrile Butadiene Styrene) plastic.

ABS is a commonly used thermoplastic polymer known for its excellent combination of properties, including good mechanical strength, impact resistance, chemical stability, and electrical insulating characteristics.

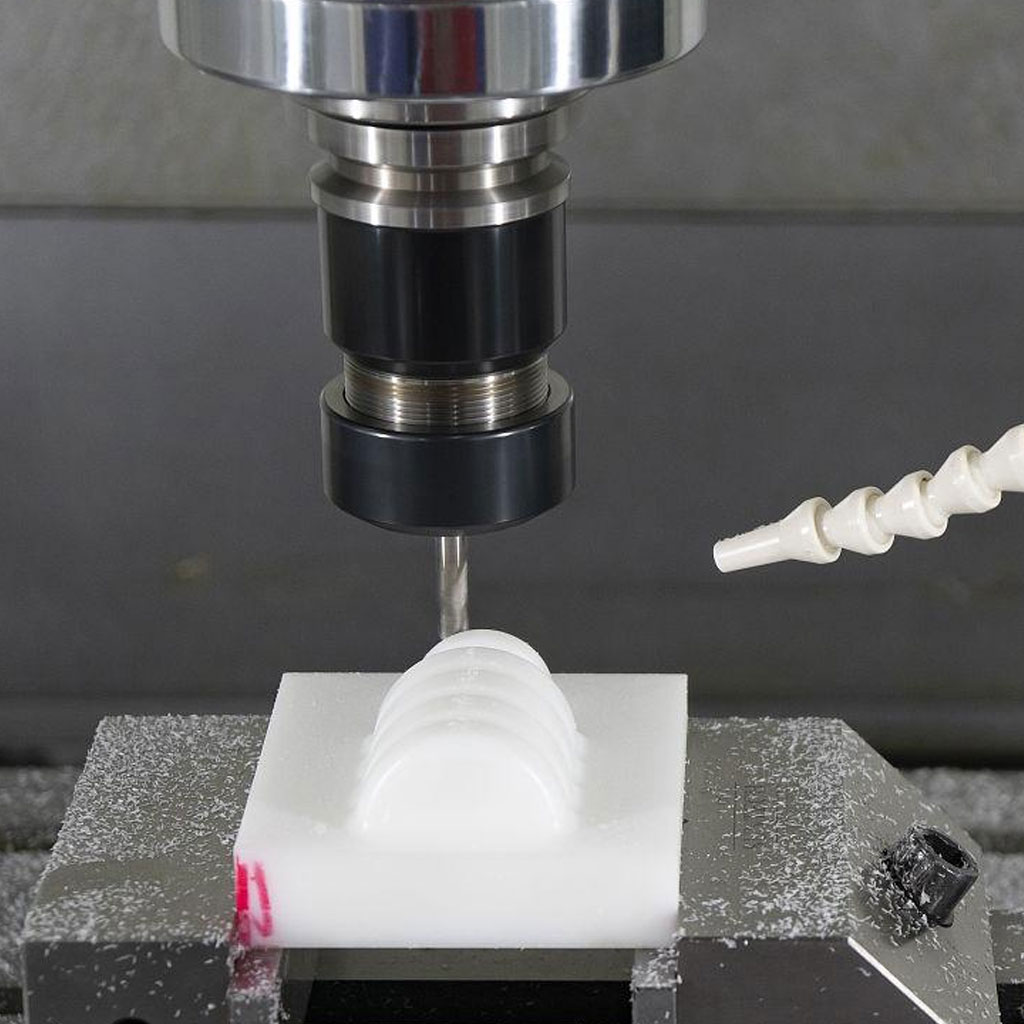

CNC Machining ABS involves using various cutting tools and processes to achieve specific shapes, dimensions, and surface finishes for parts made from this material.The machining process for ABS typically involves subtractive manufacturing methods, where material is removed from a larger piece of ABS stock to create the desired shape.

Cnc Machining ABS Parts – Machining ABS(Acrylonitrile Butadiene Styrene)

In the dynamic world of modern manufacturing, where precision and versatility reign supreme, finding a reliable partner to meet intricate production needs is paramount. Enter Be-Cu prototype, a trailblazing CNC machining company at the forefront of innovation and quality. Specializing in ABS plastic CNC machining, Be-Cu prototype has garnered a reputation for delivering impeccable results that exceed expectations. With a dedication to cutting-edge technology, meticulous craftsmanship, and a client-centric approach, Be-Cu prototype has emerged as a leader in the realm of ABS plastic machining.

ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic polymer celebrated for its exceptional blend of mechanical strength and versatility. Its superior impact resistance, chemical stability, and electrical insulating properties make it a material of choice across diverse industries, from automotive to electronics, consumer goods to healthcare products. When precision machining is required, ABS plastic presents both opportunities and challenges.This is where Be-Cu prototype’s ABS plastic CNC machining service shines. Leveraging state-of-the-art CNC technology, the company expertly transforms raw ABS plastic material into intricately designed components that meet the most exacting specifications. From rapid prototyping to full-scale production, Be-Cu prototype empowers clients with a comprehensive suite of advantages:

Uncompromising Precision

Seamless Versatility

Rapid Prototyping to Production

Material Integrity and Consistency

Cost-Efficiency

Environmental Responsibility

The table below displays an overview of the material properties, units and values for machining ABS

| Property | Units | Typical Value |

|---|---|---|

| Density | g/cm³ | 1.04 – 1.07 |

| Tensile Strength | MPa | 40 – 50 |

| Flexural Strength | MPa | 60 – 70 |

| Impact Strength (Izod) | J/m | 250 – 400 |

| Hardness (Rockwell) | – | R85 – R115 |

| Melting Point | °C | 210 – 220 |

| Specific Heat Capacity | J/g°C | 1.2 – 1.4 |

| Thermal Conductivity | W/m·K | 0.15 – 0.25 |

| Coefficient of Thermal Expansion | 1/°C | 70 – 100 x 10^-6 |

| Electrical Insulation | – | Good |

| Chemical Resistance | – | Good |

| Water Absorption | % | 0.2 – 0.8 |

Do you have specific abs cnc machining requirements? Feel free to get in touch with our abs machining experts to discuss the use of abs plastic to machine your parts for industrial applications. Our experts will respond to you at the earliest.

CNC Milling ABS

In the ever-evolving landscape of modern manufacturing, precision and innovation stand as cornerstones of success. We proudly present to you our advanced CNC Milling ABS service, an embodiment of cutting-edge technology, meticulous craftsmanship, and unwavering commitment to excellence. At Be-Cu.com, we understand that achieving the highest level of precision in creating intricate components from ABS (Acrylonitrile Butadiene Styrene) plastic is both an art and a science. With our expertise, state-of-the-art machinery, and client-centric approach, we’ve set a new benchmark in CNC milling ABS, transforming concepts into reality with unparalleled accuracy and finesse.

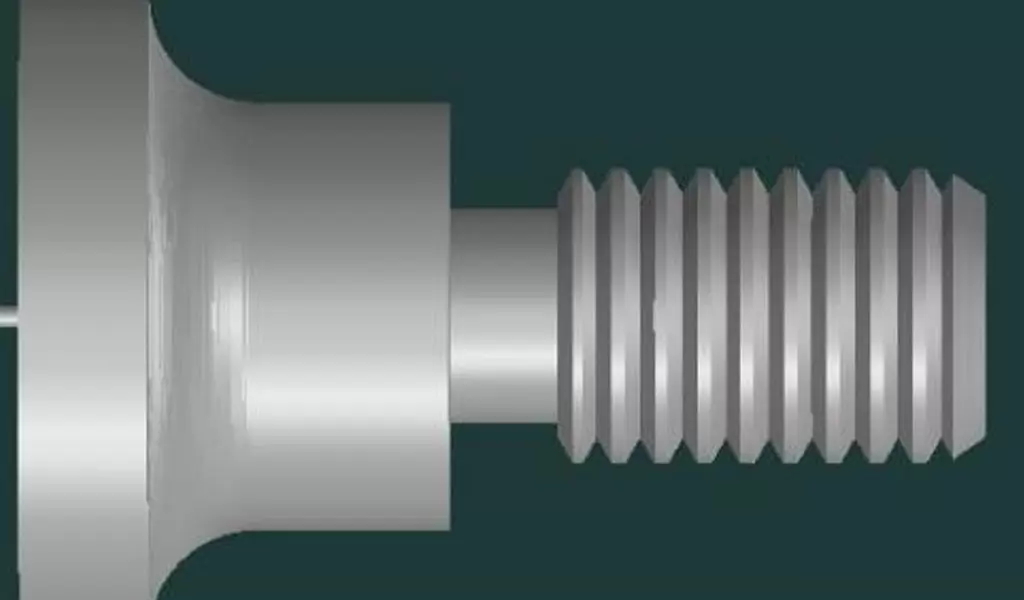

CNC Turning ABS

At Be-Cu, we’ve harnessed the power of advanced technology and unparalleled expertise to deliver exceptional CNC turning solutions for ABS (Acrylonitrile Butadiene Styrene) plastic components. With a commitment to excellence, a passion for intricate design, and a relentless pursuit of perfection, our CNC Turning ABS service redefines the art of precision engineering.Our CNC turning technology, backed by cutting-edge software and machinery, enables us to achieve micro-level precision that caters to even the most intricate geometries and tightest tolerances.

How To Ensure ABS Plastic Machining Accuracy?

Through a scientific/rigorous method and a non-impetuous mind

- The team members have 35 years of experience in plastic machining more than 100,000 precision products.

- Constant temperature cnc machining environment ●5-axis ultra-precision machining equipment, achieving 0.1μ resolution, 1μ cutting ●Equipped with ultra-high-precision Renishaw probe (on-line detection and compensation of parts during cnc plastic machining, so that the results can be seen before leaving the machine)

- Cooperate with global engineering plastics material suppliers to ensure the quality of raw materials

- ISO standardized management and evolving precision machining technology for special engineering plastics

- What can really achieve ultra-high precision for complex engineering plastic products is:

- Persistence in mission, love for the industry and not impetuous heart

Why Choose Our ABS Cnc Machining Service?

- Save time and money for your ABS project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of ABS grades and plastic materials can be machined

- Custom complex ABS machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top ABS Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make ABS prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making ABS concept models and precise functional components. Understanding the properties of different ABS plastic, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on ABS. Be-cu prototyping company provides a range of solutions for the machining of ABS plastic parts.