Aluminum Sheet Metal Fabrication

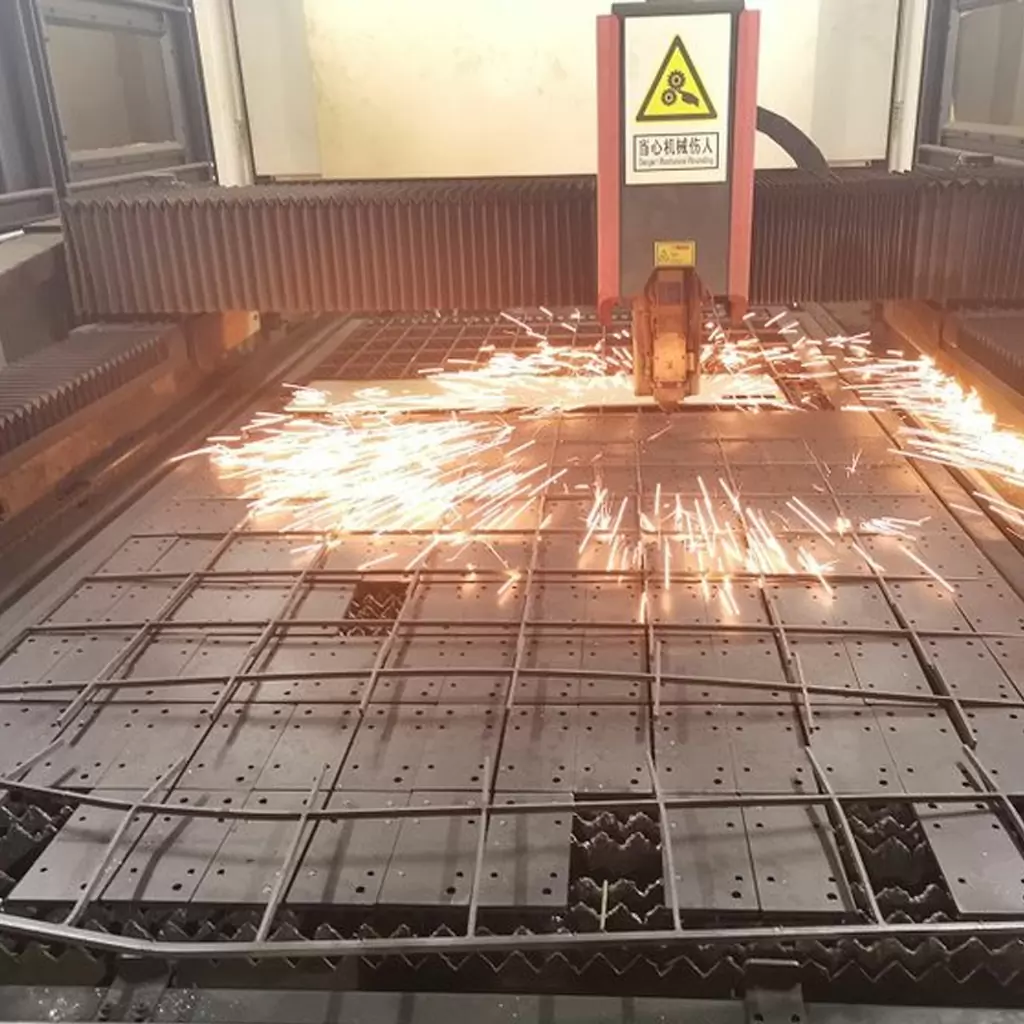

Sheet Metal Fabrication are mainly products of a variety of alloys. The commonly Sheet Metal Fabrication Aluminum parts used alloy is AL-3A21, AL-5A02和 AL-2A06, covering transportation, aerospace, electronics, and military industries.Aluminum alloys have high strength and low density. Most time, Aluminum Sheet Metal Fabrication has a high tolerance to control as much as 0.01MM. Quality and unique aluminum components can be manufactured via laser cutter and cnc bending machine. Best choice for this process is large tonnage bending, and it has high accuracy and precision in bending aluminum sheet.

Sheet Metal manufacturing in aluminum takes several processes from aluminum plate and pipe. Wide range of technologies and machines come up with the best tool design for each equipment made.

Designers and manufacturers tend to launch their products In the shortest possible time frame to save cost. A shape prototype close to the original will be manufactured.

Benefits of Aluminum In Sheet Metal Fabrication

All Aluminum have a high resistance to corrosion and heat making it a durable metal with a long lifespan.Aluminum is often able to withstand many years of use without showing signs of wear and tear. Other advantages include:

- High resistance to corrosion

- Easily cut, welded, formed, machined and fabricated readily

- Due to its strength, Aluminum can be used to reduce material thicknesses, reduce weight and costs

- 100% Recyclable

- Its unique hygienic properties makes it the first choice in hospitals, kitchens, food and pharmaceutical processing facilities

Aluminum is a popular choice for Sheet Metal Fabrication for multiple reasons. Aluminum is easy to Sheet Metal manufacturing and can be cut effectively, chipped and shaped. Due to its high machinability, it can be machined faster than other metals. Aluminum has an oxidized outer layer that offers corrosion resistance. A strong material, aluminum is suitable for parts for various industries, including aerospace, automotive, healthcare, electronics, etc. Aluminum has a high strength-to-weight ratio, and its light weight makes it perfect for aircraft and automotive pieces. Aluminum is receptive to finishing processes, including anodization and painting. Lastly, aluminum is recyclable, which helps minimize waste during manufacturing as any excess material can be repurposed.Aluminum Sheet Metal,An extremely popular material for sheet metal. It has a superior strength-to-weight ratio, is easy to fabricate and has a good price point. Also, as a strong, aesthetically pleasing, heat resistant and corrosion resistant steel, its applications are widespread. It is used for the fabrication of everything from cutlery to car parts.

The Aluminum Alloy Grades Of Metal Sheet Metal Fabrication

The commonly used aluminum and aluminum alloy plates mainly include the following three materials: rust-proof aluminum 3A21, rust-proof aluminum 5A02 and duralumin 2A06.

Anti-rust aluminum 3A21 is the old brand LF21, which is AL-Mn alloy and is the most widely used anti-rust aluminum. The strength of this alloy is not high (only higher than that of industrial pure aluminum) and cannot be strengthened by heat treatment. Therefore, the cold working method is often used to improve its mechanical properties. It has high plasticity in the annealed state, and good plasticity when it is hardened by semi-cold work. Low plasticity, good corrosion resistance and good weldability during cold work hardening.

Anti-rust aluminum 5A02 is the old brand LF2 series AL-Mg anti-rust aluminum. Compared with 3A21, 5A02 has higher strength, especially higher fatigue strength, high plasticity and corrosion resistance. Heat treatment cannot be strengthened, and the weldability by contact welding and hydrogen atom welding is good. There is a tendency to form crystalline cracks during argon arc welding, and the alloy has a tendency to form crystalline cracks during cold work hardening. The alloy has good machinability in cold work hardening and semi-cold work hardening state, but poor machinability in annealed state and can be polished.

Duralumin 2A06 is the old LY6, which is a commonly used duralumin grade. Hard aluminum and super hard aluminum have higher strength and hardness than ordinary aluminum alloys, and can be used as some panel materials, but they have poor plasticity and cannot be bent. Bending will cause cracks or cracks in the outer radius.

There have been new standards for the grades and states of aluminum alloys. The standard code for the designation method is GB/T16474-1996 and the state code GB/T16475-1996. The comparison table with the old standard is shown in Table 1-1 below:

| Aluminum Grade | Alloying Elements | Strengthening Process | Cracking | Corrosion Resistance | Finishing | Joining |

|---|---|---|---|---|---|---|

| 1xx.x | unalloyed | Non-heat-treatable | – | 1 | 1 | 1 |

| 2xx.x | Copper | Heat-treatable | 4 | 4 | 1-3 | 2-4 |

| 3xx.x | Silicon, Magnesium, Copper | Heat-treatable | 1-2 | 2-3 | 3-4 | 1-3 |

| 4xx.x | Silicon | Heat-treatable | 1 | 2-3 | 4-5 | 1 |

| 5xx.x | Magnesium | Non-heat-treatable | 4 | 2 | 1-2 | 3 |

| 6xx.x | NOT USED | NOT USED | – | – | – | – |

| 7xx.x | Zinc | Heat-treatable | 4 | 4 | 1-2 | 4 |

| 8xx.x | Tin, Copper, Nickel | Heat-treatable | 5 | 5 | 3 | 5 |

Aluminum Sheet Metal Fabrication Services – Sheet Metal Manufacturing Aluminum Parts Suppliers & Manufacturer

Bringing this all together, Laser cutter are on a rise and aluminum remains the top choice for several industry verticals. At Be-cu.com, we offer top-quality finish for sheet metal fabrication aluminum parts using fiber laser cutter and 400-3000T Bending machines as per our clients’ needs. Along with aluminum sheet metal, we also offer precision sheet metal fabrication services for other materials such as magnesium, zinc, titanium, steel, stainless steel, and many more.

Our sheet metal aluminum fabrication services’ tolerance values range from +/-0.005″ (+/-0.125mm) to +/-0.001″ (0.025mm) and Capable of forming parts from 12 in. to 90 ft. length, 0.015 to 0.125 in. material thickness to help you achieve the desired application of the part without any worries of errors or mistakes. If you are looking to produce aluminum parts, Be-cu.com is your trusted partner. Our project managers and talented pool of highly experienced engineers will collaborate with you to help you achieve your business and manufacturing goals.

Drop us an email or request a no-obligation quote for more information.

Why Use Our Aluminum Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal Aluminum parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication aluminum to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off aluminum laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom aluminum laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

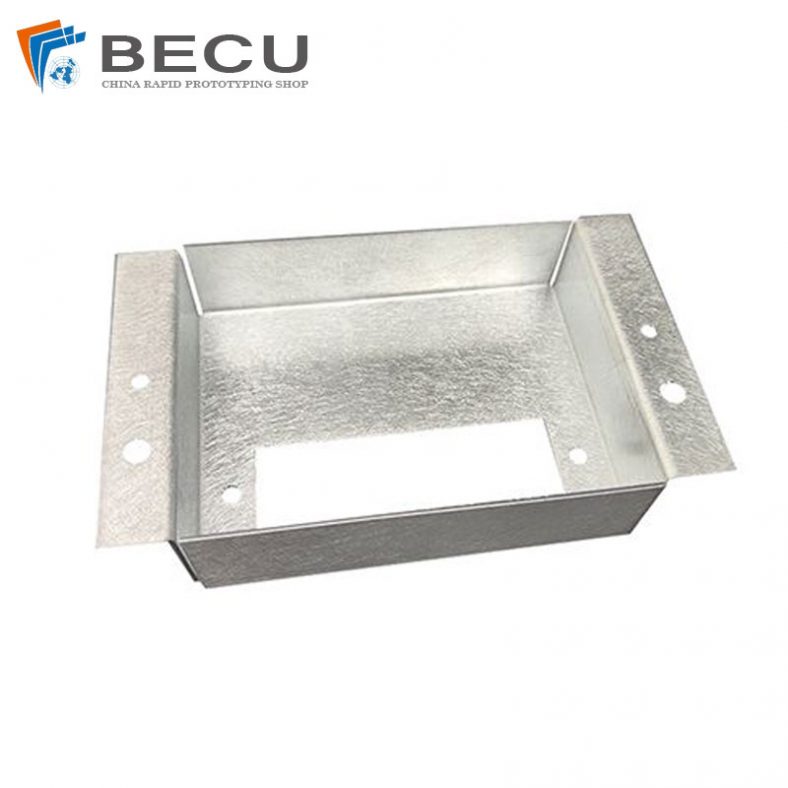

Our Capabilities And Case Studies Gallery Of Aluminum Sheet Metal Fabrication

As a single-source manufacturing solutions provider, Be-cu.com offers a comprehensive group of services, including Aluminum sheet metal fabrication.

Using sheet metal fabrication, we manufacture aluminum parts that exhibit a high degree of structural integrity.Aluminum sheet metal parts have no seams, enabling them to tolerate high pressure, and the sheet metal process itself realigns the grain structure of the metal to improve tensile strength. The enhanced metallurgical properties allow the use of lighter gauge metals to achieve the desired strength characteristics, which saves on material cost. sheet metal fabrication also results in high-quality finishes that reduce the need for secondary operations.

Inside our sheet metal fabrication department, we manufacture parts for a variety of purposes, from automotive applications to medical equipment. We have the capacity to achieve tolerances as close as ±0.005” for specialty applications that require extreme precision. Our sheet metal fabrication capabilities are supported by our machining, fabrication, and finishing departments, making the use of sheet metal fabrication virtually limitless. For more information about the sheet metal fabrication process or any of our other production capabilities, contact us directly.

-

Sheet Metal Fabrication Aluminum 5052 Medical Box For Fire Fighting

-

Sheet Metal Fabrication POS Machine Box Shell

-

Sheet Metal Fabrication Industrial Computer Bottom Cover

-

Sheet Metal Manufacturing 10.1 Inch Hardware Monitor Enclosure

-

32-Inch Medical Sheet Metal All-In-One Machine Cabinet

-

Precision Fabrication Wall Mount Gaming Computer Case Chassis

-

0.8MM All Aluminum Sheet Metal Mini Host Computer Chassis

-

3MM Fabrication Aluminum 5052 Brushed Battery Box

-

Sheet Metal Aluminum 7075 Industrial Control Chassis Accessories

-

Sheet Metal Fabrication Aluminum 6061 Tablet Computer Housing