Cnc Machining Aluminum – Machining Aluminum Specialist

Demand for aluminum is increasing year by year, and with the introduction of IT by electronic devices in usa, aluminum materials and parts are used in all situations such as semiconductor manufacturing equipment, robots, and the aeronautical automobile industry. In addition, there are many opportunities to use it from kitchen utensils used at home to household appliances, and it can be said that it is one of the most closely related metal materials to human life, along with iron.

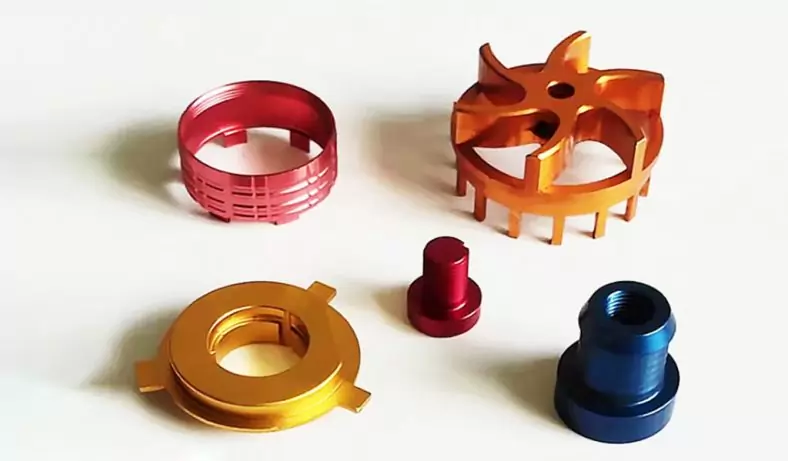

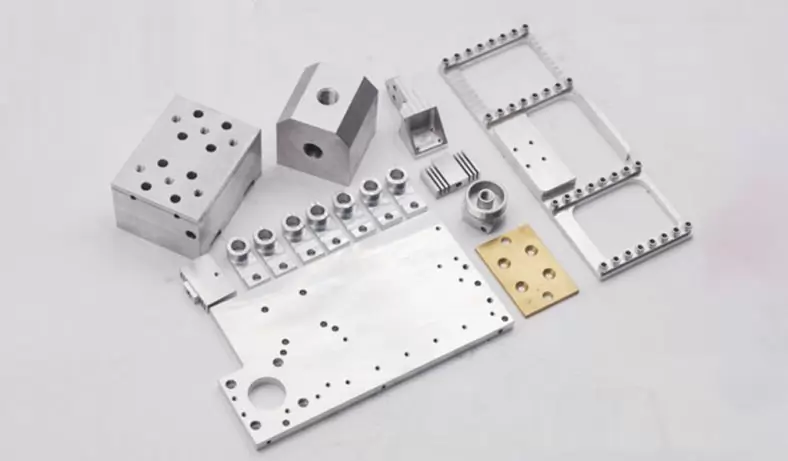

Precision cnc machined aluminum parts are becoming the choice of many industries. Aluminum is one of the most popular materials due to its excellent mechanical properties. These include affordability, flexibility, durability and corrosion resistance.

BE-CU specialize in machined aluminum CNC parts and aluminum prototype for more than 30 years, we have rich experience in quality precision aluminum machining parts. As precision machining specialist, we maintain tight tolerance and dimensions.

You can get turnkey servce inculde 3-4-5 Axis Machining,Swiss Machining,CNC Milling and Turning, Precision Grinding, Wire EDM and Machining Assembly in house, also we can provide Jig&Fixuture to make your proudction more easy.

The Cutting And Machining Characteristics Of Aluminum

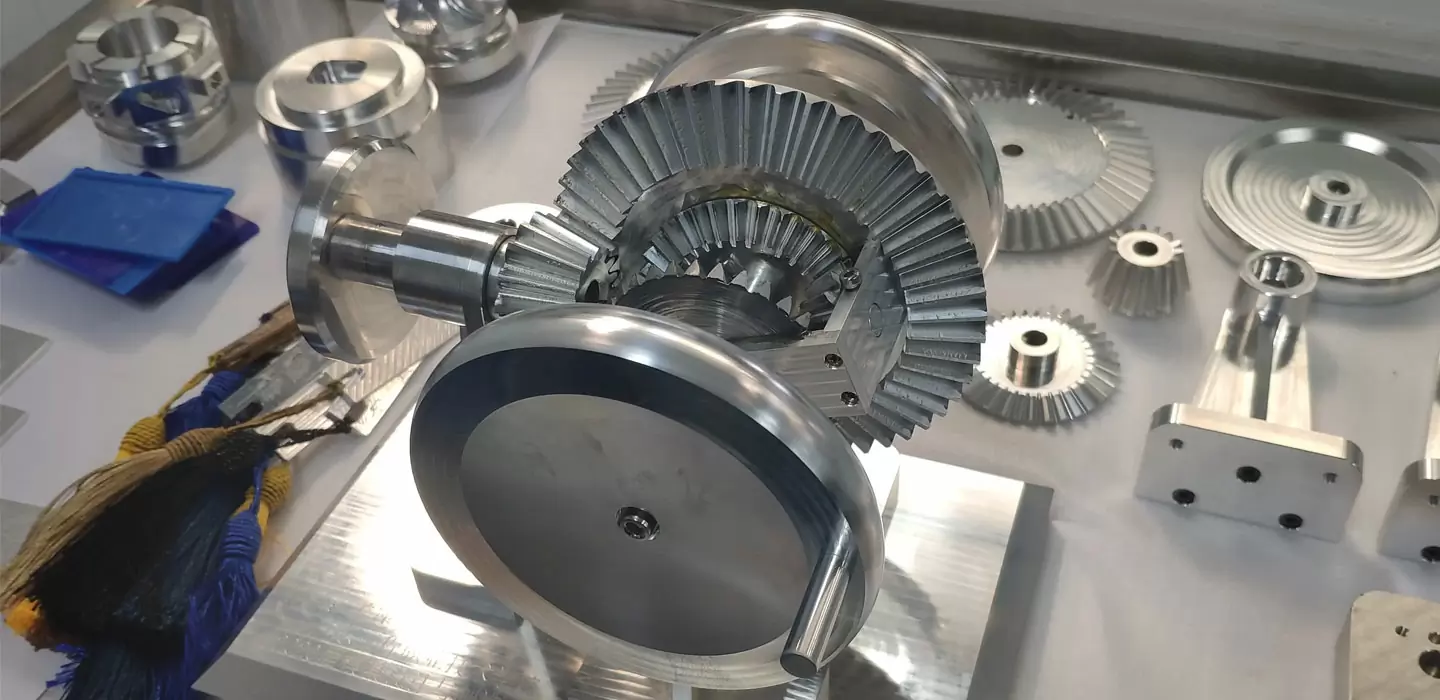

If the object is limited to aluminum, machining can be viewed from a different perspective than steel. These properties open up new uses for aluminium, where different cnc machining conditions and methods can be applied than steel. There are many types of machining, but here we will focus on cutting. Even with Aluminum, machining such as cutting, grinding, and polishing is actually used. However, cutting is the most widely used.

The latest developments in china cnc machining technology are impressive. For cnc machine, such as ultra-high-speed cnc machines with spindle speeds of tens of thousands of revolutions and machining centers that can perform various types of cuts with automatic tools and changers. As for tools, carbide tools are already common, and natural single crystal diamond tools are also used on an industrial scale. In addition, there are a large number of ultra-precision cut products that take full advantage of these technologies. The current situation is that as these technological developments are closely related to the cutting characteristics of aluminum, cutting technology is becoming more and more mature.

High Machining And Cutting Speed

It Can Be Continuously Cut For Long Time

The Wide Range Of Suitable Cutting Conditions

Less Energy Is Required For Cnc Machining

Good Cnc Machining Or Cutting Accuracy

There Are Few Restrictions On Mechanical Rigidity

High Flexibility With Respect To Machining Parts

Why Choose Our Aluminum Cnc Machining Service?

- Save time and money for your aluminum project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be machined

- Custom complex aluminum machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Aluminum Alloy Material Of Cnc Machining

Aluminum alloys can be easily machined and have a low raw material cost, making them often the most economical choice for prototyping and machined metal parts.Its density is low, around a third of that of steel, and it has an excellent strength/weight ratio, making it a very interesting structural material. It is also a non-magnetic material.

Aluminum alloys has natural protection against corrosion. In addition, it can be anodized if greater control of the external oxide layer and an aesthetic finish are desired.It has high thermal conductivity and high electrical conductivity (although anodizing is not electrically conductive).Aluminum alloy is also very suitable for cold environments. It has the advantage over steel in that its tensile strength increases with decreasing temperature, while retaining its hardness. Steel, on the other hand, becomes brittle at low temperatures.

Top China Aluminum Cnc Machining Parts & Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make aluminum prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making aluminum concept models and precise functional components. Understanding the properties of different aluminum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on aluminum alloy. Be-cu prototyping company provides a range of solutions for the machining of aluminum parts.

-

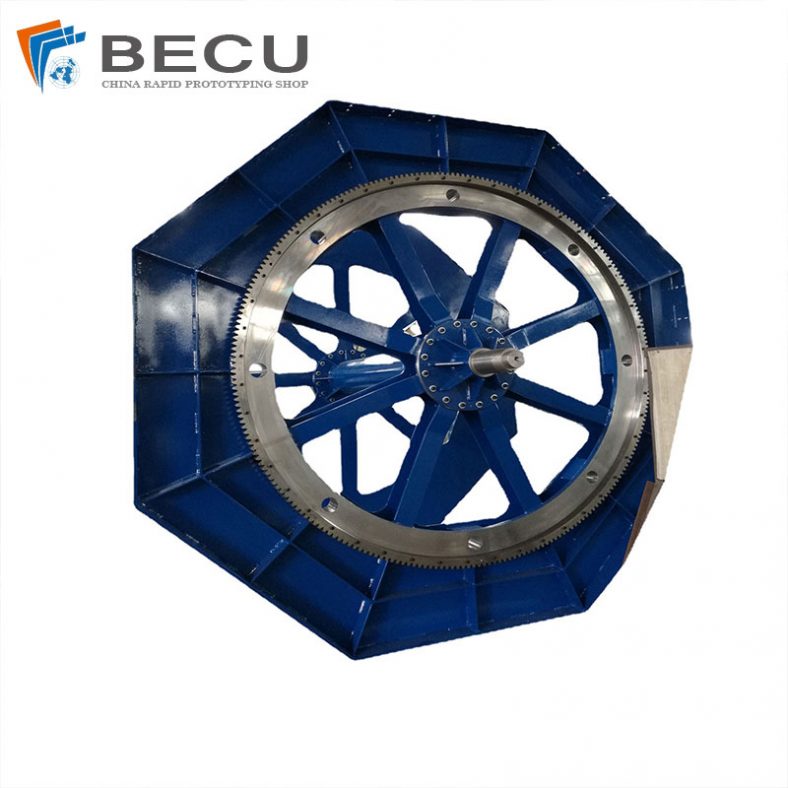

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

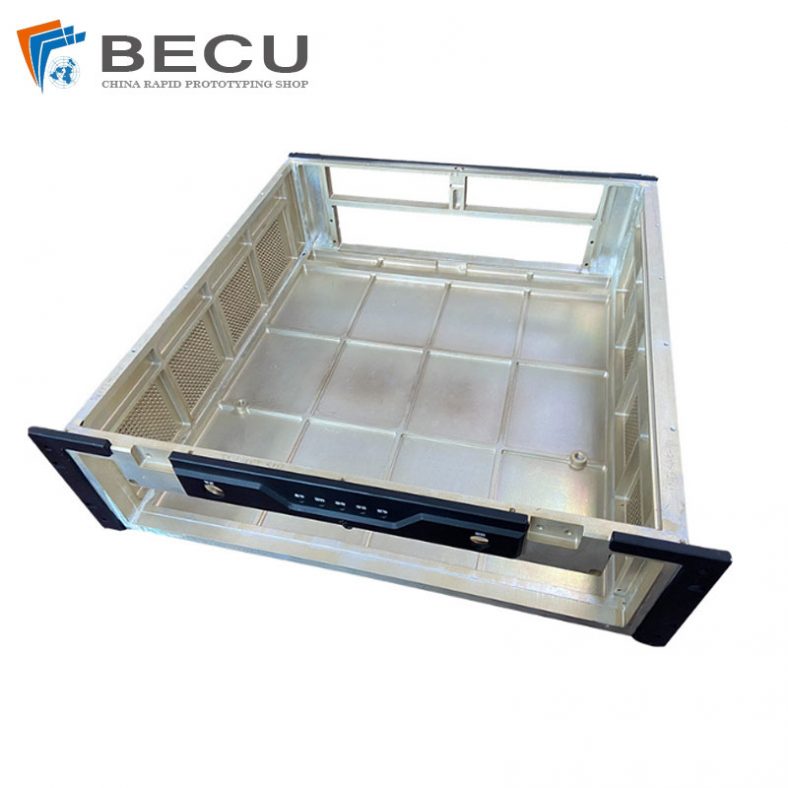

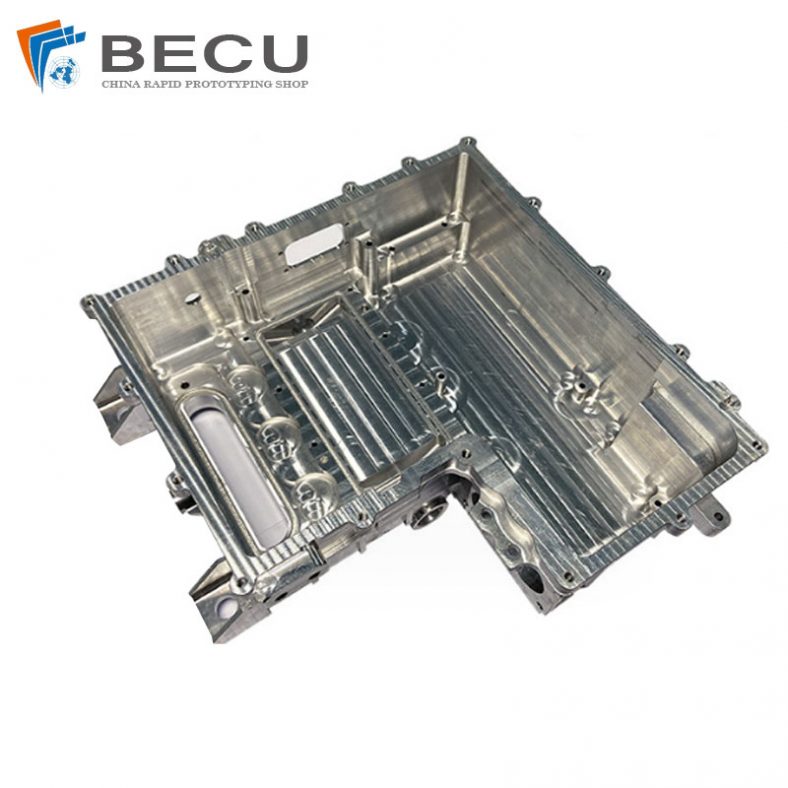

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

CNC 6063 Aluminum Automotive Motor End Cover

-

CNC Machining Gas Stove Bottom Joint

-

CNC Turning 6063 Bicycle Tightening Disc

-

Precision CNC Machining Unmanned Aerial Vehicle Motor Base

-

Metal CNC Machining Motor Front And Rear Covers

-

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

-

CNC Machining For Camera L Bracket

-

Welding CNC Machining 5M Drum For Centrifugal Fan

-

Large Machining Micro-Automation Robots Joint

-

CNC Machining 6061-T1 Electromagnetic Clutch Parts

-

Precision Machining 6061-T1 Automobile Motor Prototype

-

Precision Machining Security Door Lock Guard Housing

-

Custom Electron Optical Instrument Sight Bracket